OWNER’S GUIDE

PIRANHA® RESTAURANT FIRE SUPPRESSION SYSTEM

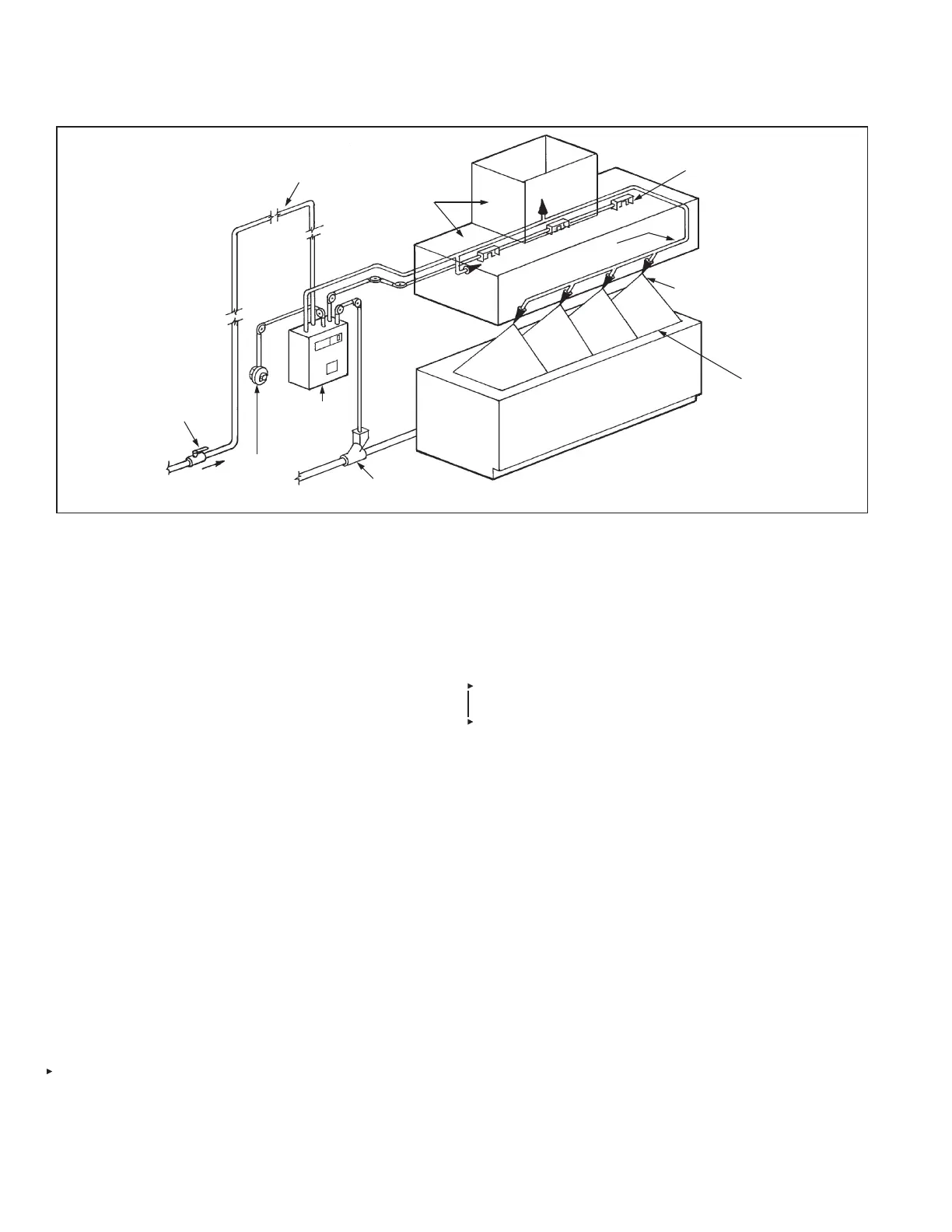

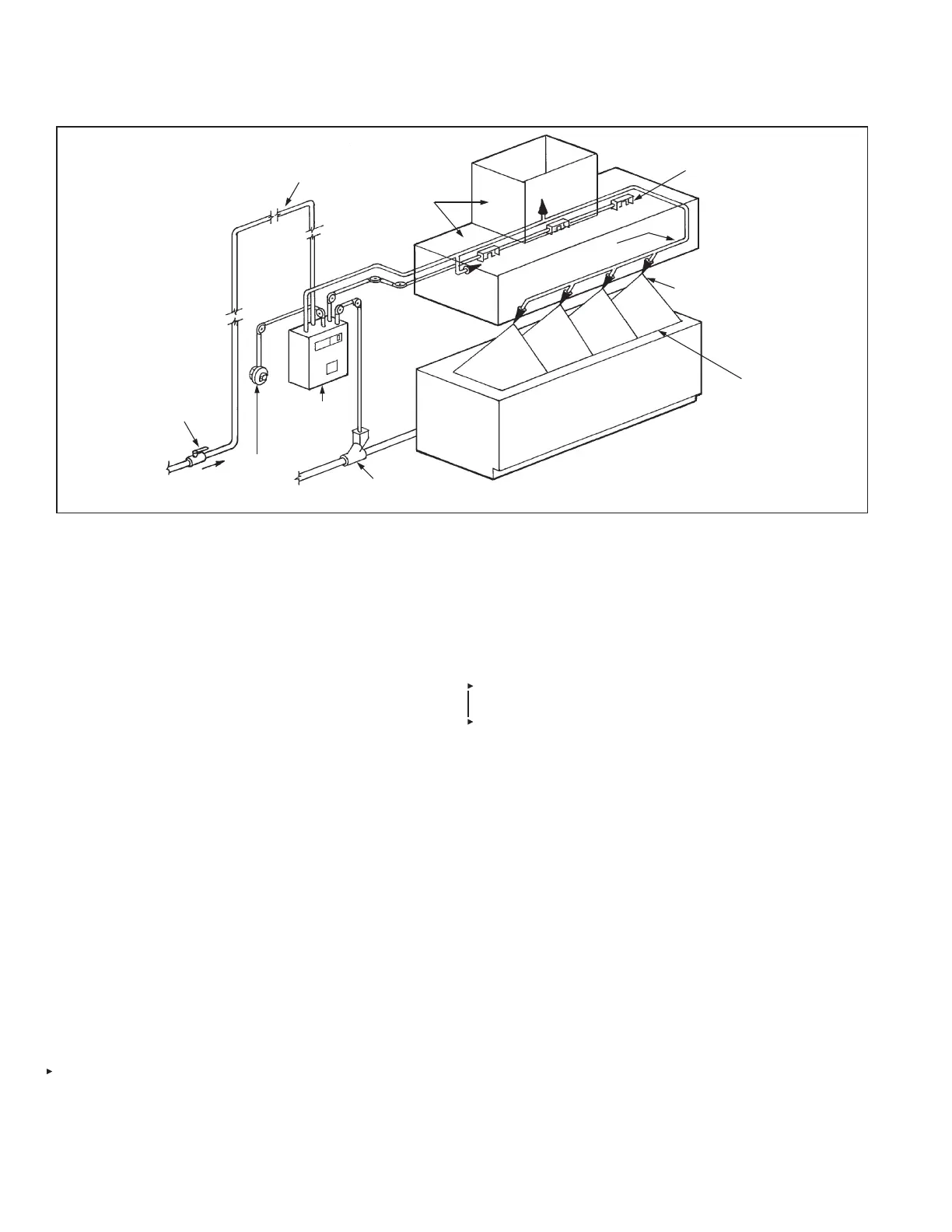

HOW THE ANSUL PIRANHA RESTAURANT FIRE

SUPPRESSION SYSTEM OPERATES

1. A fire starts in the protected area…

2

. Heat sensitive fusible link detectors activate the

system.

3. Appliance energy sources are automatically shut off by

accessory equipment appropriate for the type of fuel

used by your cooking equipment.

4. The fire extinguishing agent is discharged into the

plenum and duct and onto the cooking appliances.

5. The agent and the hot grease mix to form a foam. This

temporarily seals combustible vapors, helping to inhibit

re-ignition. This seal must not be disturbed.

6. Immediately following the agent discharge, water will

start discharging through the same piping network. The

addition of the water adds to the foam layer and helps

cool the hot grease and appliance faster.

INSPECTING YOUR PIRANHA FIRE SUPPRESSION

SYSTEM

Your PIRANHA Fire Suppression System should be

inspected at least monthly. Should you discover any

irregularities, contact an authorized ANSUL distributor

immediately

.

1. Never use corrosive cleaning solutions on the fusible

links or cables. Check to make certain there is no

corrosion to any of the detection system components.

Certain high alkaline cleaners could cause corrosion.

2

. Ensure that metal fusible links are replaced semi-annu-

ally. Deterioration of these links could cause the system

to be actuated or to malfunction in case of a fire.

3. Make certain the releasing unit has not been tampered

with, and that visual inspection seals are not broken or

missing.

4. Make certain the manual water shut-off valve(s) (not

required on self-contained systems) is locked in the

OPEN position.

5. At daily intervals check your system for loose pipes and

missing or grease covered nozzle caps. Make certain

nozzle caps are in place over the ends of each nozzle.

Temporarily remove cap, check to make certain it is not

brittle, and snap back on nozzle.

Note: If caps are damaged or missing, contact the

authorized ANSUL distributor for immediate

replacement.

6. Check each metal blow-off cap and make certain the

cap can be turned freely on the nozzle.

7.

Periodically check your visual indicator on the releasing

unit to make certain the system is cocked.

8. Have your system inspected by an authorized ANSUL

distributor at a maximum of 6 month intervals and

immediately after major hood and duct cleaning. Often

fusible links are wired shut during the cleaning process

to prevent accidental activation This will prevent the

system from operating automatically. It's also possible

that your system might have been disconnected,

damaged, or has accumulated excessive deposits of

grease causing your system to become inoperative.

9. Check that the manual pull station is not obstructed, has

not been tampered with, and is ready for operation.

10. Make certain that each tank and releasing unit is

mounted in an area with a temperature range of

32 °F to 130 °F (0 °C to 54 °C).

11. Make certain piping connected to each tank is not heat-

ed to a temperature in excess of 130 °F (54 °C). Metal

pipe may conduct the heat to the metal tank/

adaptor assembly, heating the agent to elevated

temperatures.

2

MANUAL

PULL

STATION

GAS VALVE FOR

FUEL SHUTOFF

PROTECTED

AREA

FUSIBLE LINK DETECTOR

DISCHARGE

PIPING

DISCHARGE NOZZLE

WATER LINE

LOCKABLE

BALL VALVE (NOT

REQUIRED ON SELF-

CONTAINED SYSTEMS)

AGENT

STORAGE

TANK AND

RELEASING

UNIT

PROTECTED

AREA

001637

Loading...

Loading...