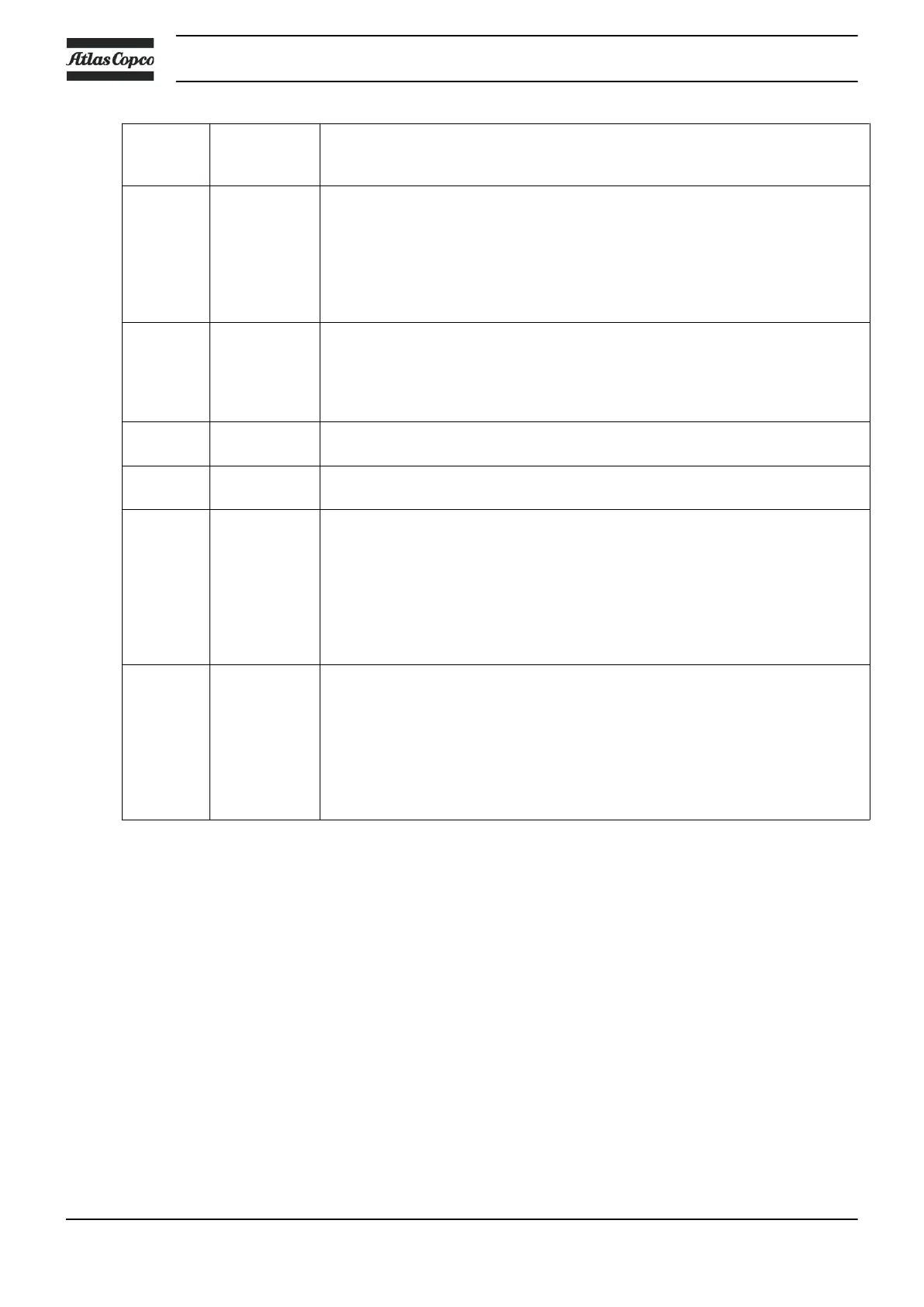

Period

(note 1)

Running

hours

(note 1)

Operation

Every 6

months

(note 2)

-- Compressors with integrated dryer:

• If dirty, brush or blow off the finned surface of the dryer's condenser.

• Inspect and clean the electronic drain:

• Functioning of the drain can be checked by pushing the TEST

button of the drain.

• Cleaning of the drain filter can be done by opening the manual

drain valve during a few seconds.

Yearly 2500 • Replace the air inlet filter(s) (AF) and the prefilter mats on the cooling air

intake openings (if fitted) (note 2).

• Test the safety valve.

• Have temperature protection and motor overload tested.

• Check tension and condition of the V-belt(s).

Every 2

years

5000 • Replace the V-belt(s).

• Replace check valve.

Every 2

years

5000 8 bar and 116 psi compressors:

Have the orbiting scroll bearing greased (see note 3).

Every 2

years

5000 10 bar and 145 psi compressors:

• Replace the element outlet pipe and the plastic insert. See section Outlet

pipe replacement.

(Only on SF 1, SF 2 and SF 4)

• Clean fan (FN1 - see Flow diagram), fan duct and element cooling fins

(see note 2).

• Have orbiting scroll bearing and pin crank bearings greased (see note 3).

• Replace tip seals and dust seal (see also note 4).

Every 4

years

10000 8 bar and 116 psi compressors:

• Replace the element outlet pipe and the plastic insert. See section Outlet

pipe replacement.

(Only on SF 1, SF 2 and SF 4)

• Clean fan (FN1 - see Flow diagram), fan duct and element cooling fins

(see note 2).

• Have orbiting scroll bearing and pin crank bearings greased (see note 3).

• Replace tip seals and dust seal (see also note 4).

Notes:

1. Maintenance must be done according the number of running hours or according the running period,

whichever comes first.

2. More frequently in a dusty environment.

3. Important note: Greasing of the bearings of the compressor element must be done with special

grease, a special grease gun and according a specific procedure.

In high ambient conditions, the bearings must be greased more frequently: for every 5 °C (9 °F)

increase above 30 °C (86 °F), the maintenance interval should be reduced with 30 %.

Contact your supplier for details.

4. In extremely dry conditions (relative humidity below 15 %), the tip seals and dust seals need to be

replaced more frequently.

Instruction book

28 2920 7110 11

Loading...

Loading...