100

912.199.3 - GB

ISTRUCTIONS PERTAINING TO THE INSTALLER

• RemovethepressuregaugefromtheP1OUTportandconnecttotheP2OUTportofgasvalve2.

• TurntheadjusterscrewK2ofgasvalve2soastosetthepressurevalue(Pout)asindicatedintable2.1

for natural gas (G20) and in table 2.2 for propane (LPG):

• CheckthattheCO

2

value at minimum heat output is as indicated in table 2.1 or 2.2. The value can be

optimizedbymakingthenecessaryneadjustmenttoscrewK2.

13.3 GAS CONVERSION

IMPORTANT: in the event of converting the boiler from natural gas (G20) to propane (LPG), the following

operation must be carried out before proceeding to adjust the gas valve as described above:

• Formodelswithonevalve,replacethediaphragmonthegasvalveoutlet(gure12a).

To replace the diaphragm, disassemble the gas valve by undoing the inlet and outlet ttings, then unscrew

the nozzle with a pair of straight round nose pliers.

Check the uid-tightness of the gas ttings removed previously.

• Formodelswithtwogasvalves,replacethediaphragmlocatedattheventuriinlet(gure12b).

To enable this operation, the gas valve manifold must rst be removed.

Check the uid-tightness of the gas ttings removed previously.

• SetparametersH536 - H541 - H608 - H609 - H610 - H611 - H612 - H613 by way of the display on the

control panel.

The values to be set are given in tables 2.1 and 2.2. The programming methods are described in chapter 14.

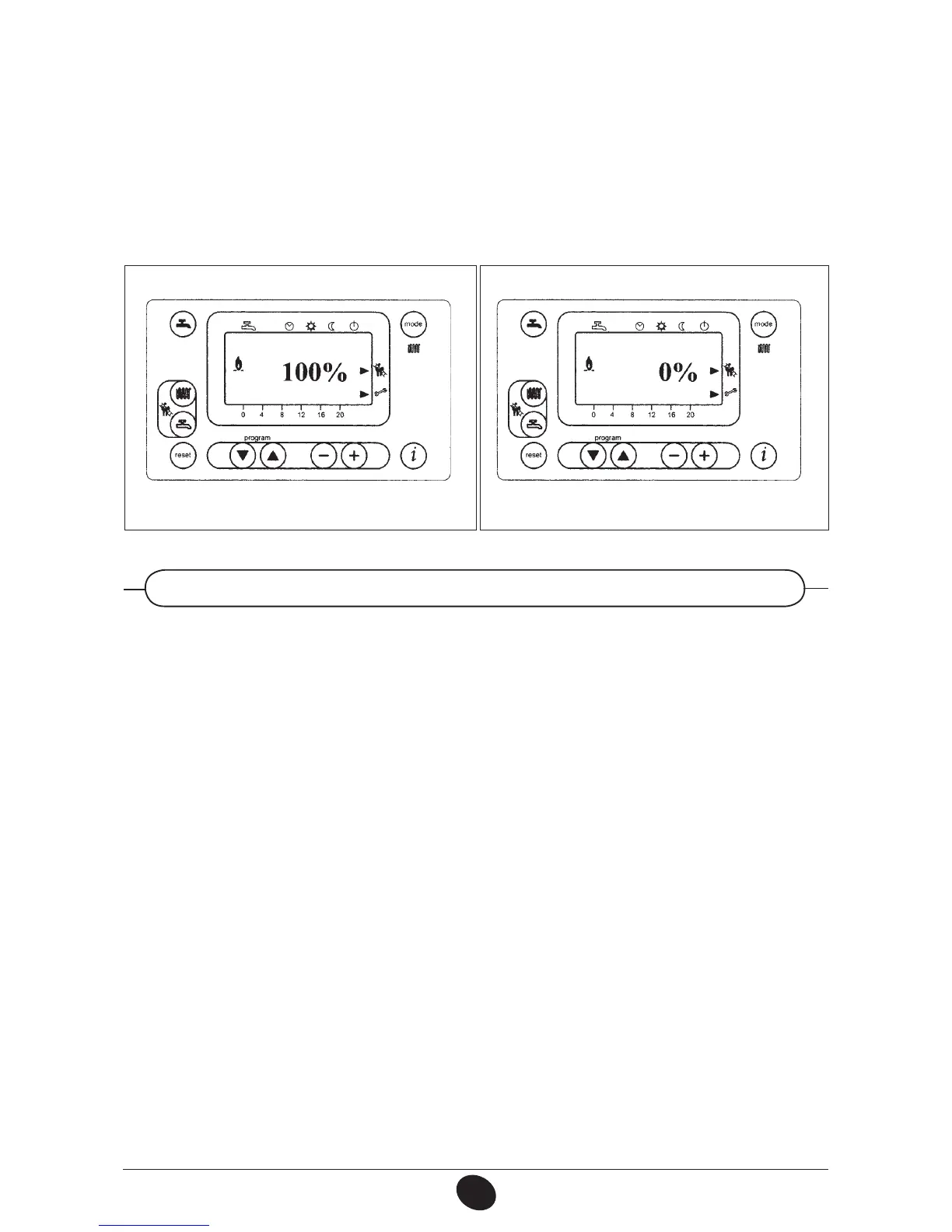

Figure 13a

0307_2201

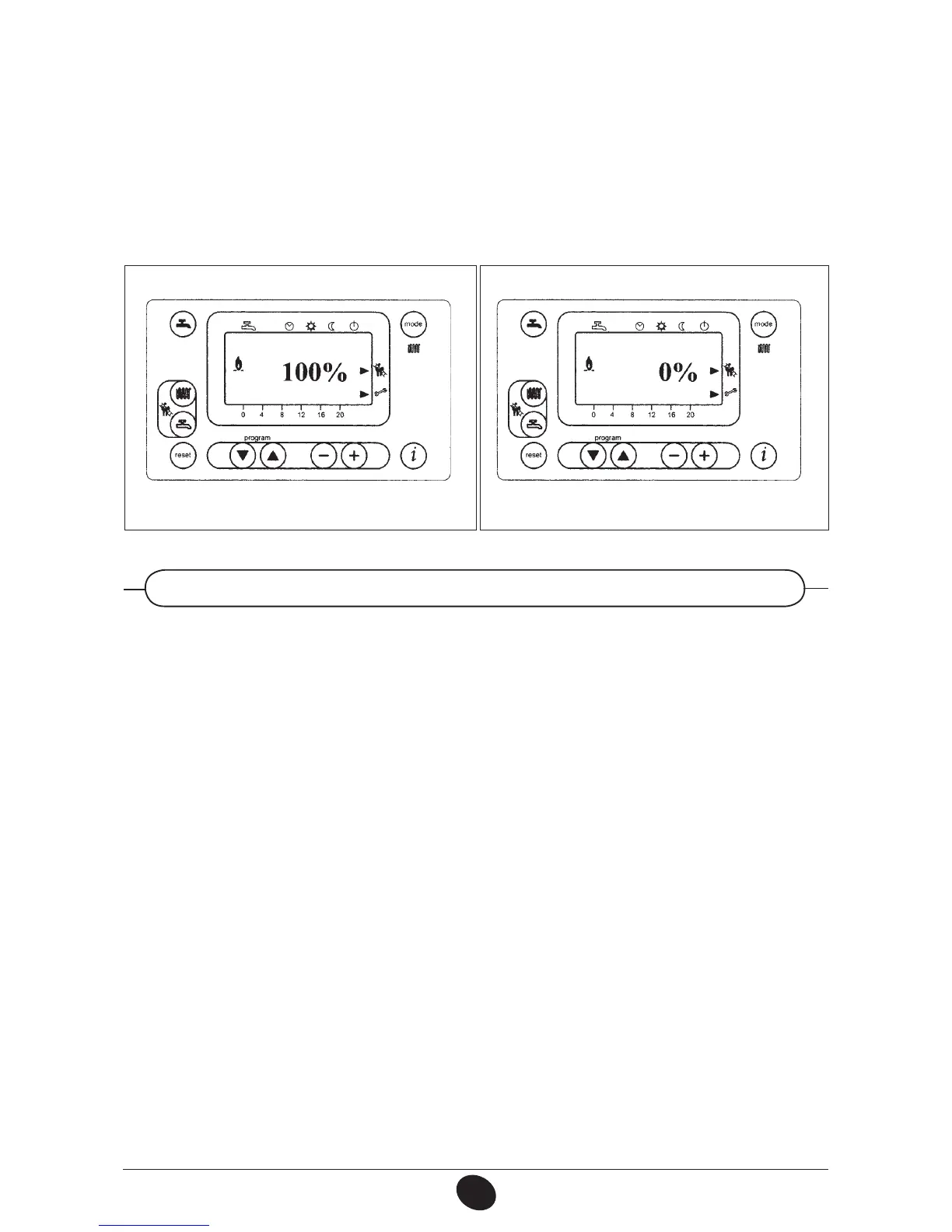

Figure 13b

⇑

⇑

0502_2110

Loading...

Loading...