60

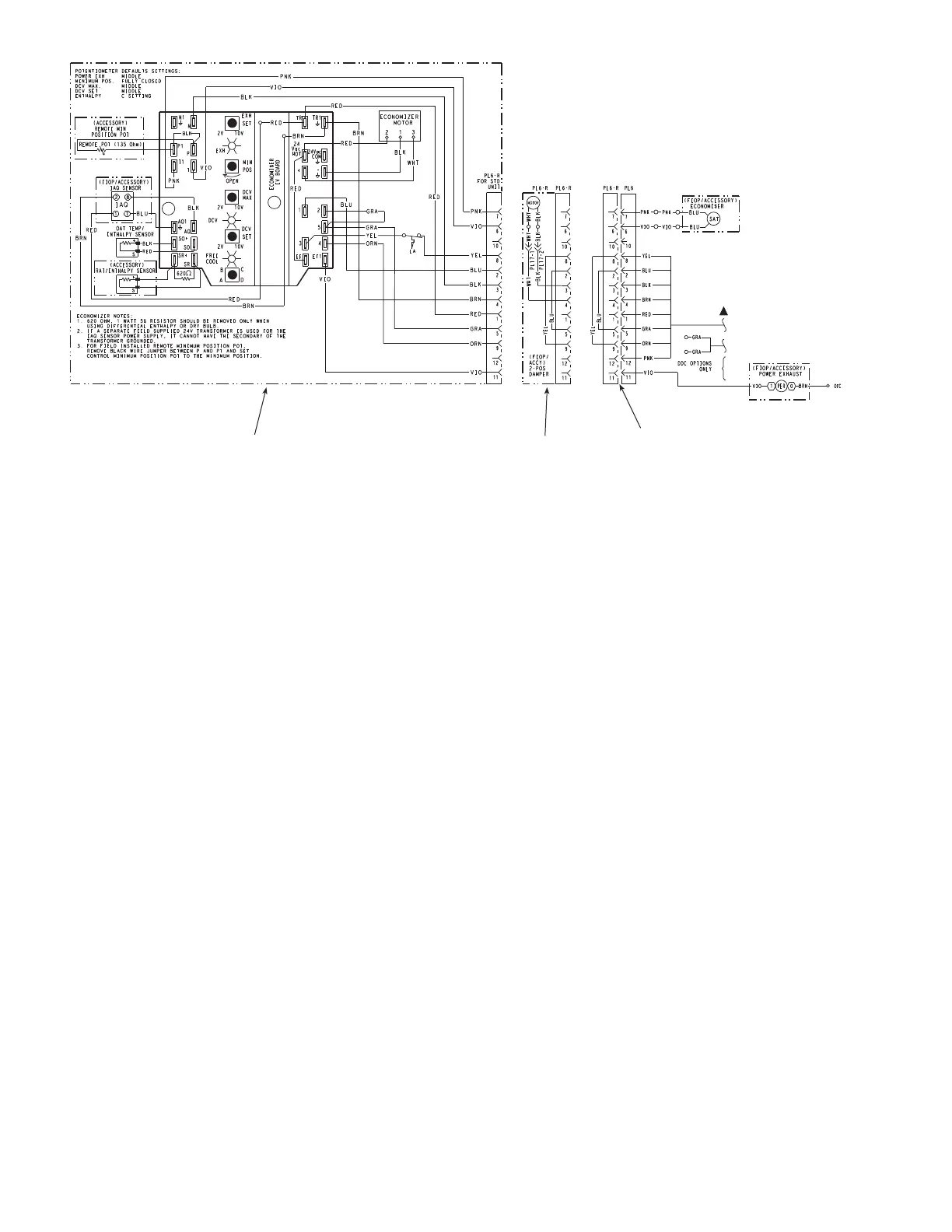

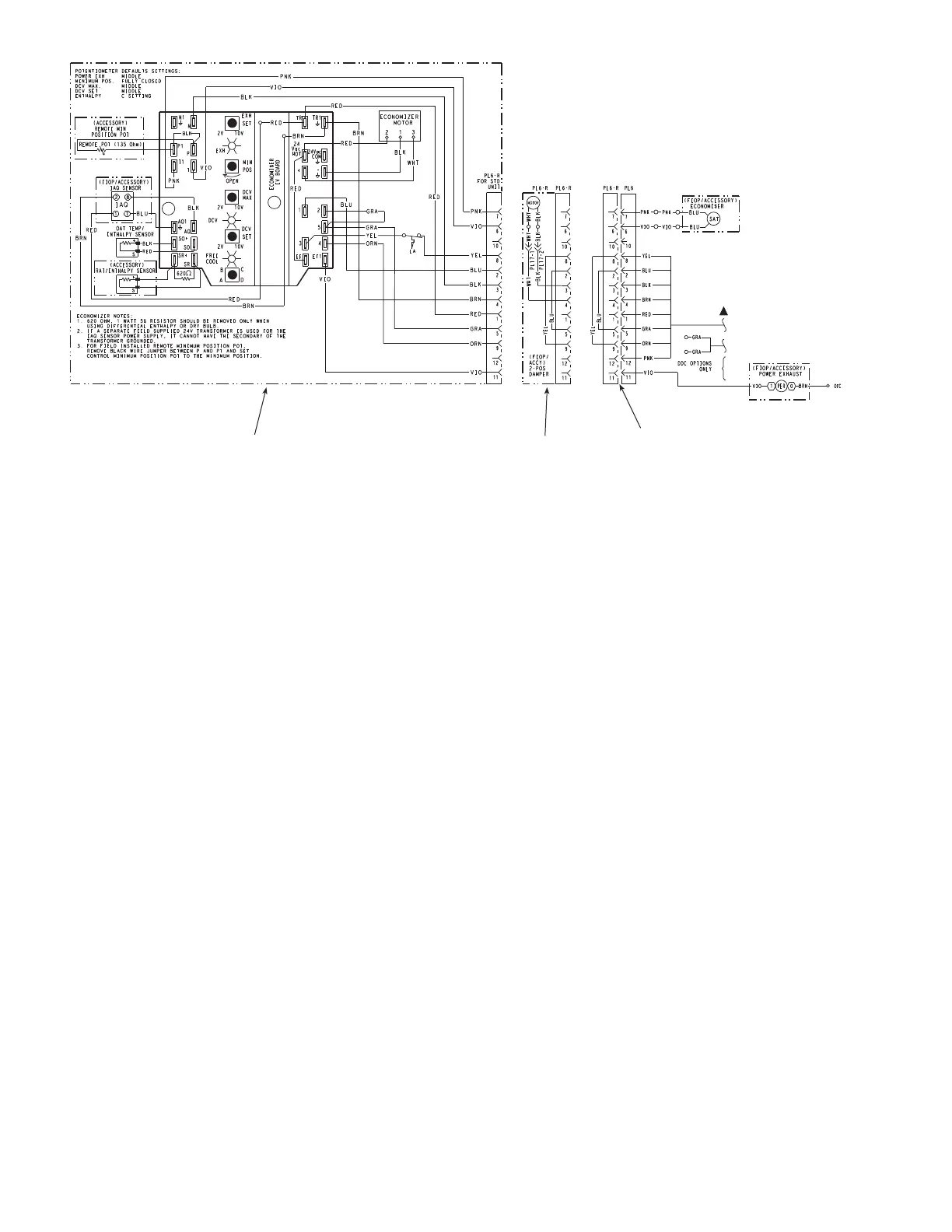

Fig. 67 — EconoMi$er

®

IV Wiring

Step 12 — Adjust Factory-Installed Options

ECONOMI$ER IV OCCUPANCY SWITCH

Refer to Fig. 67 for general EconoMi$er IV wiring. External occu-

pancy control is managed through a connection on the Controls

Connections Board.

If external occupancy control is desired, connect a time clock or

remotely controlled switch (closed for Occupied, open for Unoc-

cupied sequence) at terminals marked OCCUPANCY on CTB.

Remove or cut jumper JMP 2 to complete the installation.

Step 13 — Install Accessories

Available accessories include:

• Roof curb

• Thru-base connection kit (must be installed before unit is

set on curb)

• LP conversion kit

• Manual outside air damper

• High altitude gas kit

• Flue discharge deflector

• Low ambient controls

• Thermostat/sensor

• Two-position motorized outside air damper

• EconoMi$er2 (without control/for external signal and inte-

grated barometric relief)

• EconoMi$er IV (with control and integrated barometric

relief)

• Power exhaust

• Differential dry-bulb sensor (EconoMi$er IV)

• Outdoor enthalpy sensor

• Differential enthalpy sensor

•CO

2

sensor

• DDC interface (PremierLink)

• Louvered hail guard

• Phase monitor control

• Winter start kit

Refer to separate installation instructions for information on in-

stalling these accessories.

Step 14 — Check Belt Tension

Measure the belt span length as shown in Fig. 68. Calculate the re-

quired deflection by multiplying the belt span length by

1

/

64

. For

example, if the belt span length is 32 inches:

32 x

1

/

64

=

1

/

2

inch deflection.

BELT FORCE — DEFLECTION METHOD

Check the belt tension with a spring-force belt force deflection

gage (available from drive belt manufacturer).

1. Place a straightedge along the belt between the two pulleys.

Measure the distance between the motor shaft and the blower

shaft.

2. Set the tension gage to the desired tension (see Table 1 in

Fig. 68). Place the large O-ring at that point.

3. Press the tension checker downward on the belt until the large

O-ring is at the bottom of the straightedge.

4. Adjust the belt tension as needed.

Adjust belt tension by loosing the motor mounting plate front bolts

and rear bolt (see Fig. 69) and slide the plate towards the fan (to

reduce tension) or away from the fan (to increase tension). Ensure

the blower shaft and motor shaft are parallel to each other (pulleys

aligned). Tighten all bolts securely when finished.

BELT TENSION METHOD

Requires belt tension gage that measures tension in belt in units of

lbs force (see Fig. 68).

ECONOMIZER 2 POSITION DAMPER

UNIT WITHOUT ECONOMIZER OR

2 POSITION DAMPER

Loading...

Loading...