4

Removing the Return Air Filters

1. Remove the return air filter and indoor coil access

panel. See Fig. 1.

2. Reach inside and remove filters from the filter rack.

3. Replace these filters as required with similar replace-

ment filters of same size.

4. Re−install the return air filter and indoor coil access

panel.

Outdoor Air Hood

Outside air hood inlet screens are permanent

aluminum−mesh type filters. See Fig. 2. Inspect these

screens for cleanliness. Remove the screens when

cleaning is required. Clean by washing with hot

low−pressure water and soft detergent and replace all

screens before restarting the unit. Observe the flow

direction arrows on the side of each filter frame.

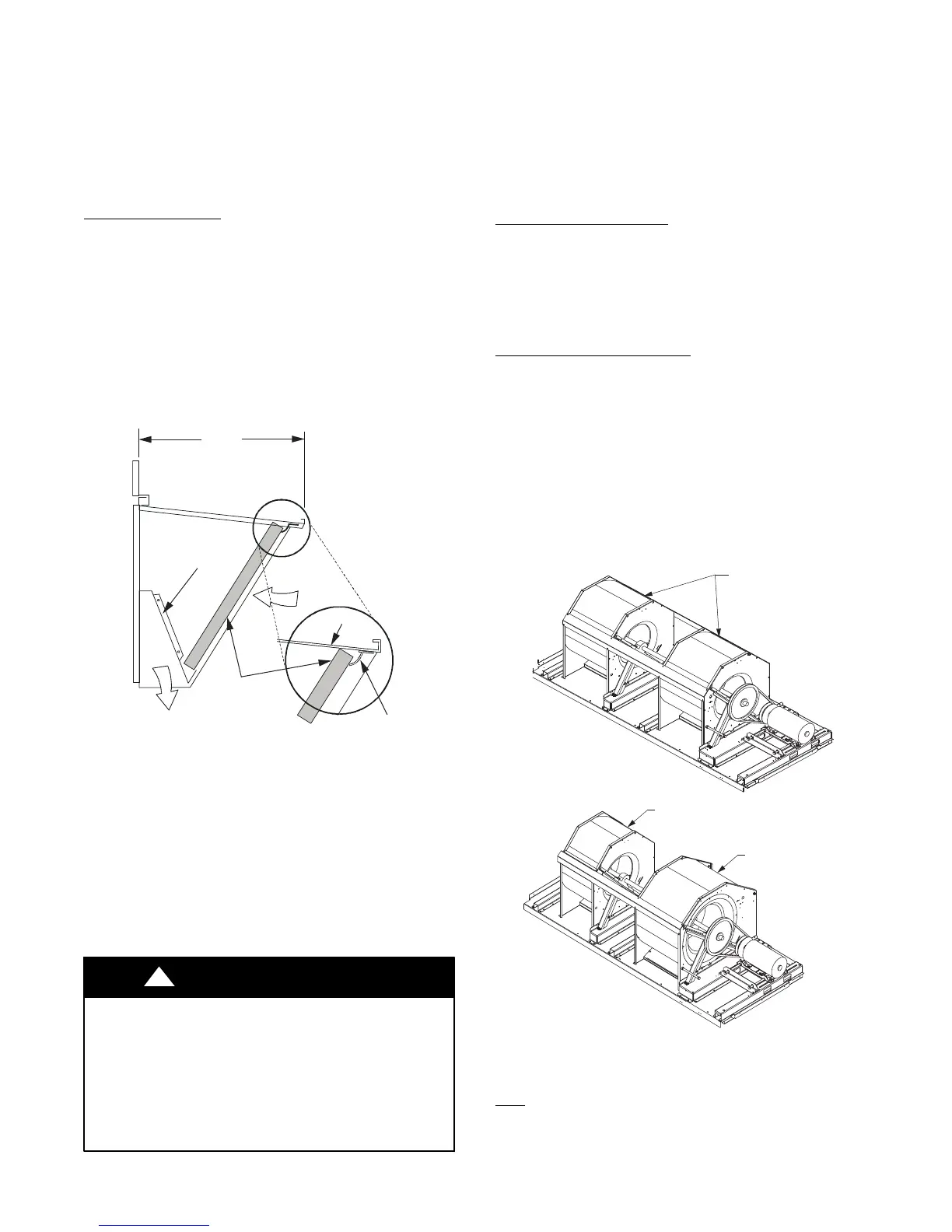

Economizer Inlet Air Screen

This air screen is retained by spring clips under the top

edge of the hood. (See Fig. 3.)

CLEANABLE

ALUMINUM

SCREEN

HOOD

FILTER

CLIP

OUTSIDE

AIR

BAROMETRIC

RELIEF

DIVIDER

17 1/4

(438 mm)

C06027

Fig. 3 − Inlet Air Screen Installation

Remove screens be removing the screws in the horizontal

clips on the leading edge of the hood. Slide the filters out.

See Fig. 3.

Install the filters by sliding clean or new filters into the

hood side retainers. Once positioned, re−install the

horizontal clips.

SUPPLY FAN (BLOWER) SECTION

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on the fan system, shut off all unit power and

Lockout/Tagout the unit disconnect switch. DO NOT

reach into the fan section with power still applied to

the unit.

!

WARNING

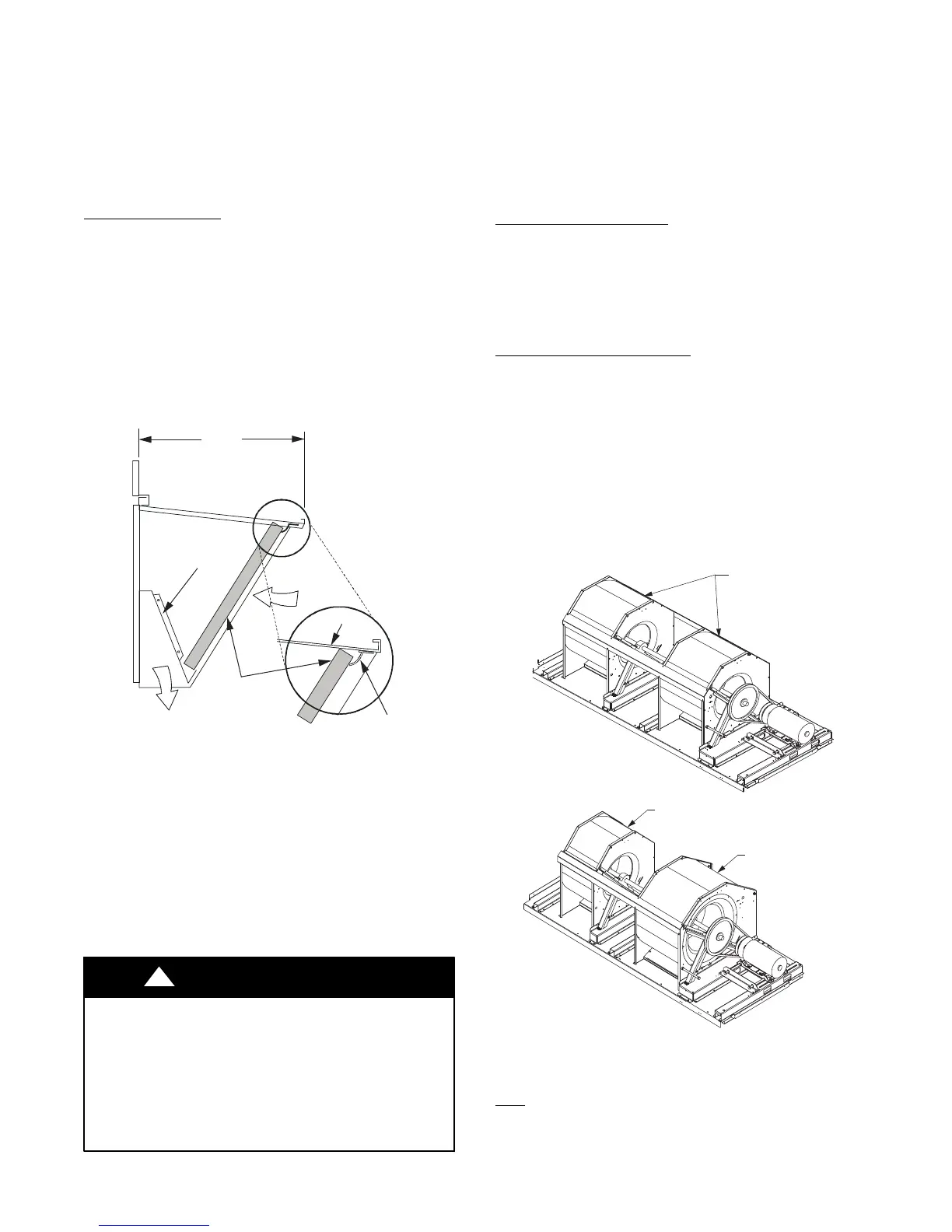

Supply Fan Assembly

The supply fan system consists of two forward−curved

centrifugal blower wheels mounted on a solid blower shaft

that is supported by two greasable pillow block concentric

bearings. A fixed−pitch driven fan pulley is attached to

the fan shaft and an adjustable−pitch driver pulley is

mounted on the motor. The pulleys are connected using a

V−belt. (See Fig. 4.)

Vertical Supply Models

The two fan wheels used on the vertical supply models are

the same: 15″ diameter x 15″ width. This arrangement

provides uniform airflow distribution across the width of

the evaporator coil, electric heater, and into the supply

duct.

Horizontal Supply Models

The horizontal supply models have two different fan

wheel sizes on a single shaft. The front side wheel is 18″

diameter x 15″ wide, while the rear side fan is 15″

diameter x 11″ wide. This arrangement promotes uniform

airflow across the width of the evaporator coil and heater

assembly while using a supply outlet on the rear side of

the unit.

NOTE: This major difference in the fan system design

makes it impossible to field−convert the 50TC unit’s

supply fan outlet configuration.

VERTICAL SUPPLY FANS

HORIZONTAL SUPPLY FANS

15” X 15” SUPPLY FANS

15” X 11” SUPPLY FAN

18” X 15” SUPPLY FAN

C12683

Fig. 4 − Supply Fan Arrangements

Belt

Check the belt condition and tension quarterly. Inspect the

belt for signs of cracking, fraying or glazing along the

inside surfaces. Check belt tension by using a spring−force

Loading...

Loading...