I

NSPECTION & MAINTENANCE

Daily

Check items shown each day. Report problems to your

supervisor. See Service Manual for maintenance and

repair procedures.

100-Hour

Every time the lift truck is serviced or every 100 hours of

truck operation, whichever comes first, complete the

following maintenance procedures:

•Check for loose or missing bolts, worn or

damaged hoses, hydraulic leaks, and

damaged or missing fork stops.

•Inspect clearance between sideshifter lower hooks and

truck lower carriage bar (Refer to Step 4, Installation).

Tighten lower hook capscrews to 120 ft.-lbs (165 Nm).

500-Hour

After each 500 hours of truck operation, in addition to the

100-hour maintenance, perform the following procedures:

•Tighten backrest capscrews (Cascade) to

145 ft.-lbs. (195 Nm).

•Apply general-purpose lithium-based chassis grease to

Sideshifter upper and lower bearings.

1000-Hour

After each 1000 hours of truck operation, in addition to the

100 and 500-hour maintenance, perform the following

procedures:

•Inspect upper and lower bearings for wear. If any

bearing is worn to less than 3/32 in. (2.5 mm) thickness,

replace the entire bearing set. See Service Manual for

replacement procedure.

•Inspect forks for wear (Use Cascade fork bar wear

gauge 209560 and fork wear calipers 686093).

WARNING: After completing any service

procedure, always test the sideshifter

through five complete cycles. First test

with no load, then test with a load to make

sure the attachment operates correctly

before returning it to the job.

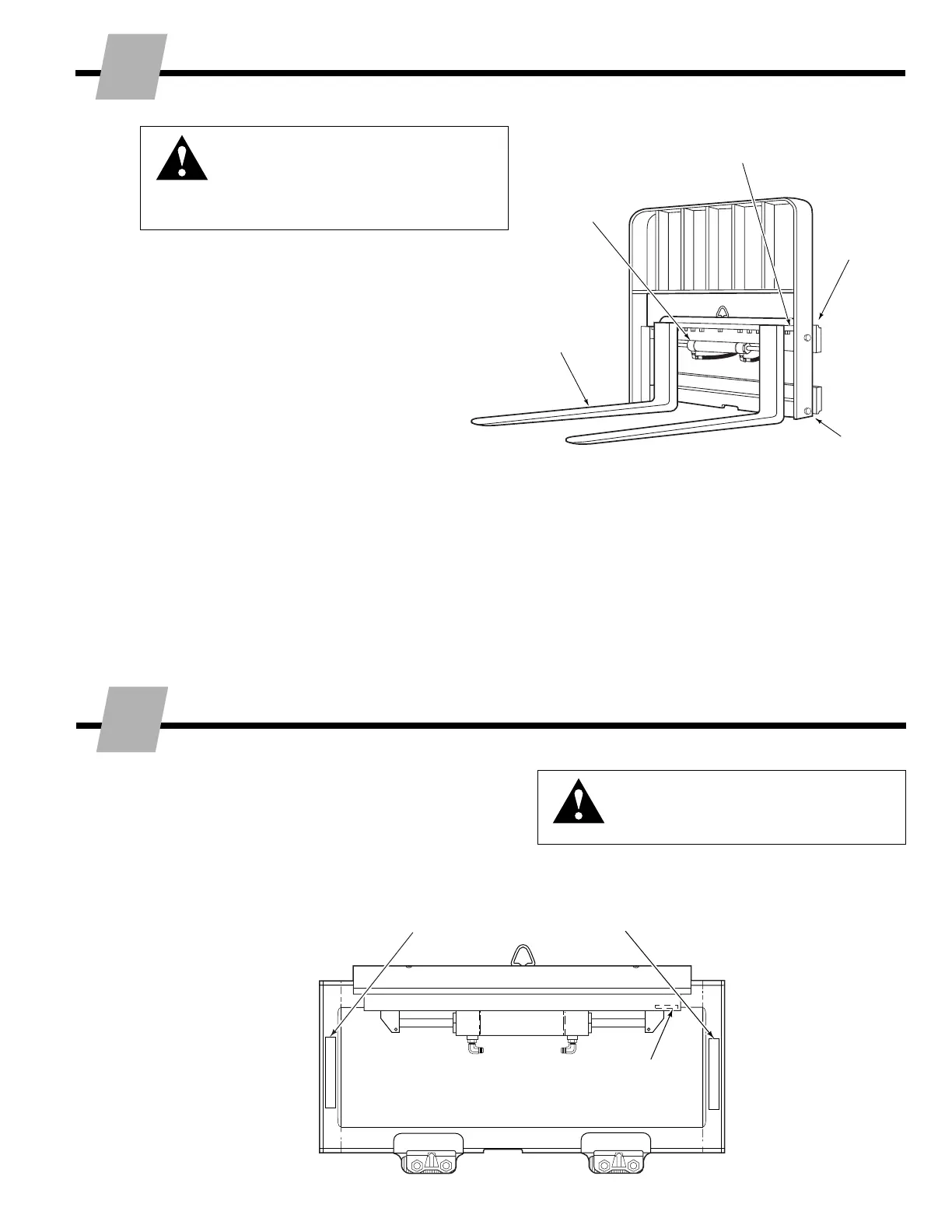

Product Identification – This Section shows replacement

parts for F-Series Sideshifters. The product model number

and serial number are stamped on the back surface of the

LH vertical bar (driver's view), and must be provided when

ordering replacement parts. The cylinder/anchor bracket

assembly part number is stamped on the front surface RH

end of the anchor bracket (driver's view).

ARTS

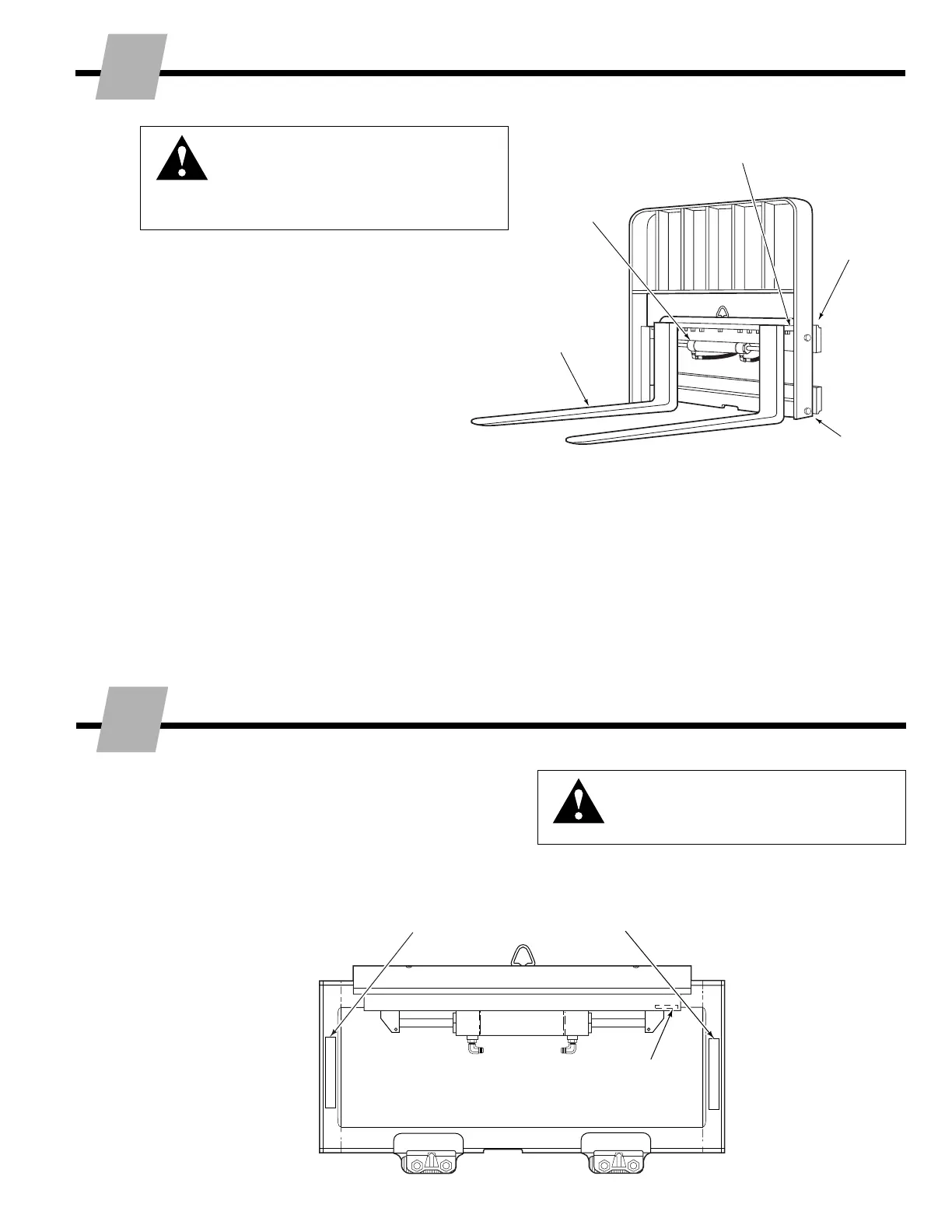

Back (Driver's) View

WARNING: For the safety of yourself and

others, DO NOT install the parts shown in

this Manual unless you have thoroughly

reviewed the appropriate Service Manual.

SS0186.ill

Forks

Hydraulic

Cylinder,

Hoses

Upper and

lower hook

engagement

Fasteners

SS0158.ill

Fork

Stops

Stamped model number,

serial number, specifications.

Sticker showing patent numbers,

phone numbers for service.

P

Stamped cylinder

assembly part number

(opposite side).

Loading...

Loading...