GENERAL MAINTENANCE

11

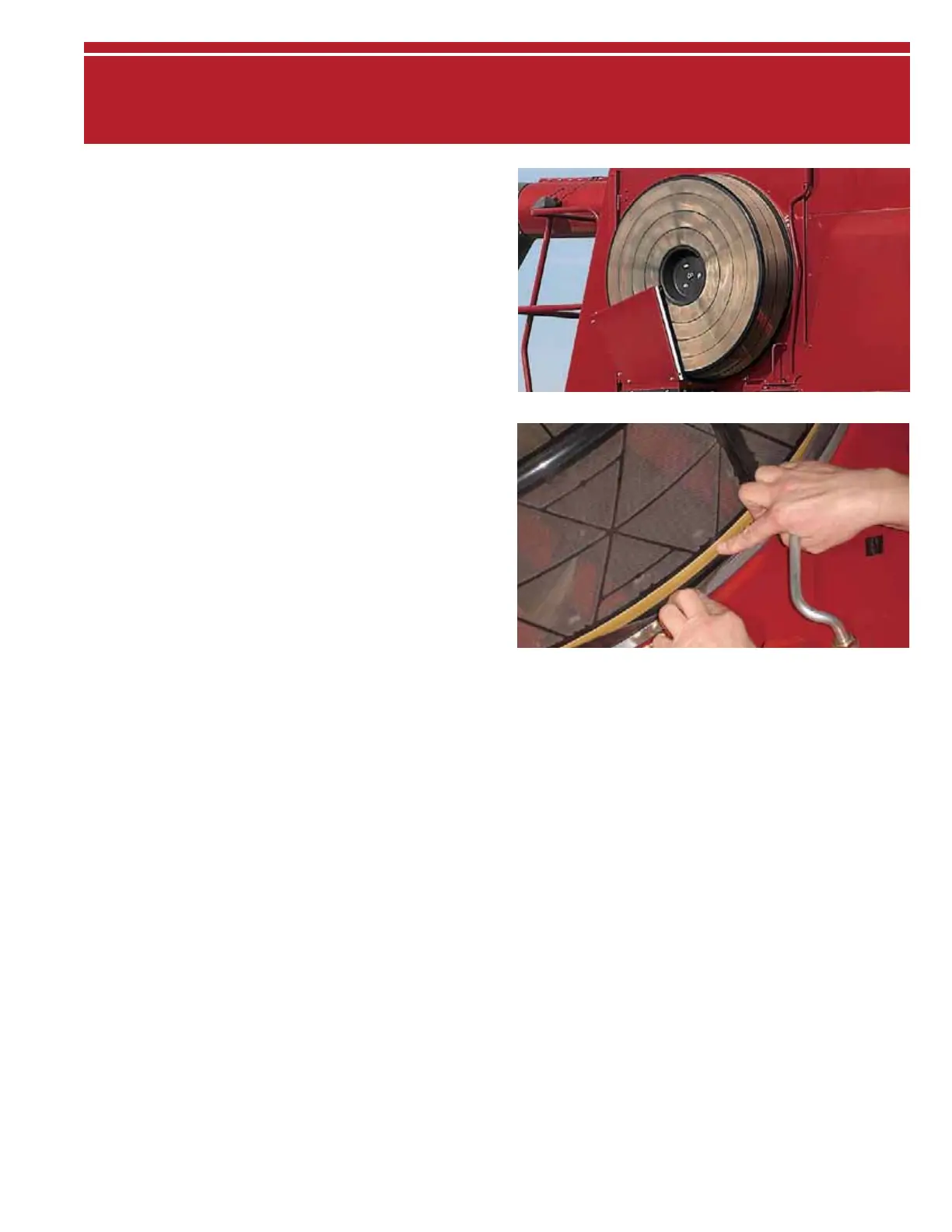

Air Intake Rotary Screen

Rotate the rotary screen to assure screen sections are not

damaged, out of place, or missing

(see figure 11.1). Also check

screen rollers for freedom of movement, brush condition, and

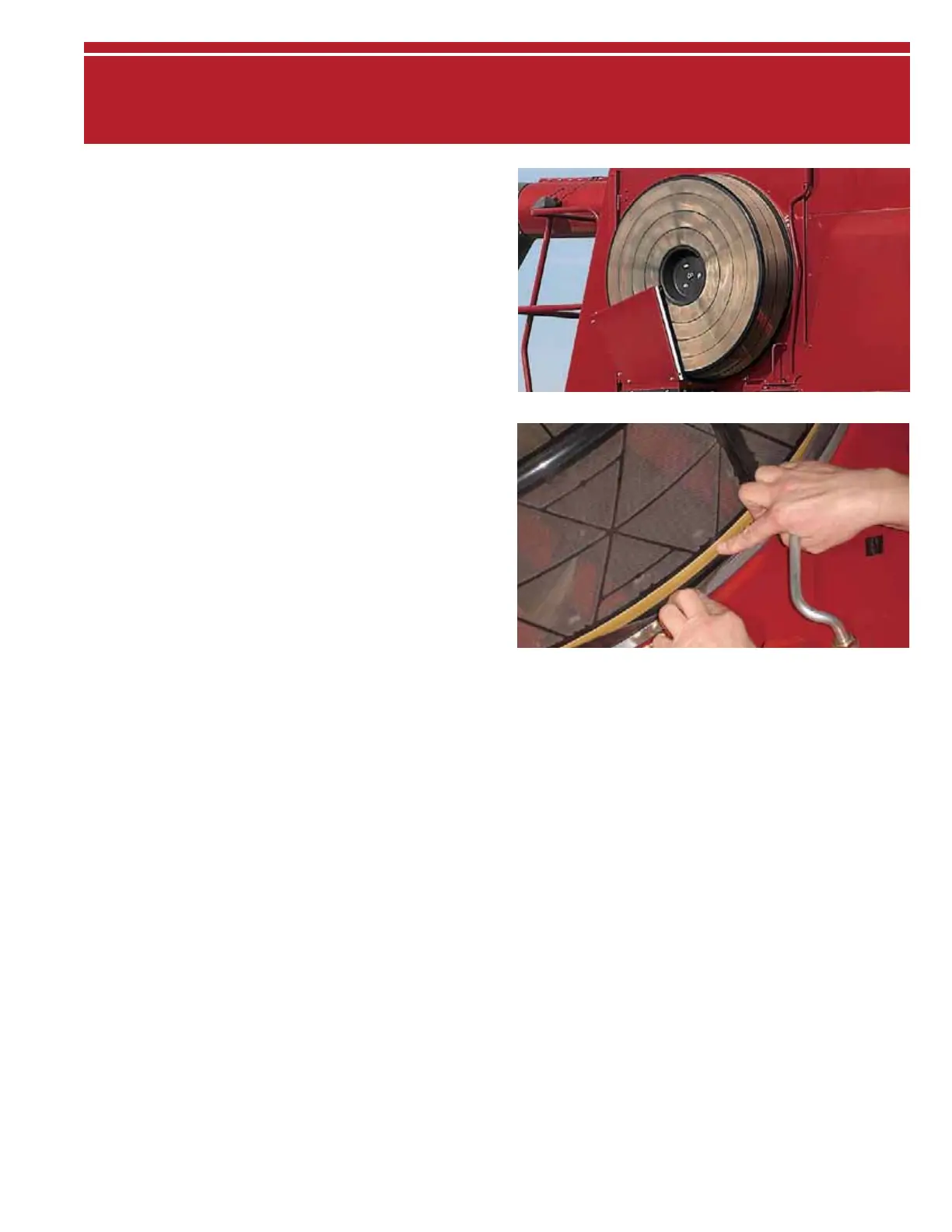

the external rubber seal condition. Lift the rubber seal and

inspect the yellow wear strip for deterioration or excessive wear

while rotating screen

(see figure 11.2).

Air Conditioning

Operators must be sure not to cover the cab air conditioner

re-circulation filter behind the seat. The area can become a

“catch-all” and the filter becomes covered up with jackets,

lunches, paper towels, etc. Keep the area clean for best air

quality conditions.

Bio-diesel Fuel

The use of bio-diesel fuel is on the rise. A bio-fuel blend, up to

a maximum of 5% (B5) has been approved for use in Case IH

diesel engines. While bio-diesel has distinct advantages such

as its clean burning characteristics, users of bio-diesel should

be aware of some specific conditions.

• Bio-diesel blends attract more moisture, and may require

more frequent water separator draining

• Bio-diesel should not be left in engines that are stored more

than four months

• A lower cloud point may contribute to harder cold-weather

starting, making bio-diesel less attractive than conventional

diesel fuel for winter use

• Depending on fuel quality, more frequent filter changes may

be required

In addition to low-emissions, some other bio-diesel advantages

include:

• Bio-diesel mixes well with conventional diesel fuel

• Oil change intervals remain unchanged are not affected with

bio-diesel use

As with all other fuels, purchase high quality bio-diesel fuel

from known reputable suppliers to assure trouble-free combine

operation.

Wheel Bolt Torque

Wheel bolt torque must be checked when new and periodically

thereafter. Refer to the Operator’s Manual for correct torque

for your combine. An accurate torque wrench is necessary to

confirm correct tightening values.

Welding on Combines

Microcomputers and solid state electrical components have

become a way of life, and today’s combines are no exception.

This makes it essential that special precautions be taken

prior to welding ANYWHERE on the combine. Solid state

components have little tolerance for errant voltage. The high

current flow during the welding process can damage sensitive

controllers and components on the combine, with disastrous

consequences.

• Disconnect ALL battery cables prior to welding. This includes

positive AND negative cables.

(The electrical system uses

two 12-volt batteries connected in parallel. This means that

both positive cables connect to the electrical system, and

both negative cables connect to ground.)

• Follow Operator’s Manual safety instructions for cable removal,

disconnecting negative cables first, and re-connecting negative

cables last

Corn Head Stalk Roll Bearing Maintenance

(Older Corn Heads prior to 1993)

Corn heads built since 1992 have sealed front stalk roll

bearings. Older heads required consistent maintenance and

correct adjustment to achieve the best possible bearing life.

1. Grease the stalk rolls with Case IH 251H EP grease every

four operating hours.

2. Add grease until excess flows from the bearings to flush dirt

and debris from bearings.

3. Adjust the height of the divider points to provide clearance

between the roll points and the ground. Avoid running the

head extremely low and allowing the rolls to contact the

soil surface.

4. Thoroughly grease the bearings before storing the corn head.

Figure 11.1

Figure 11.2

Loading...

Loading...