OPERATION

13

Rock Trap

The mechanical rock trap on the 2300 Series combines is

mounted at the top of the feeder housing, directly in front

of the rotor. The rock trap uses a three-blade beater to direct

stones from the crop flow from the feeder to the rotor downward

into the rock trap

(see figure 13.1). The rock trap will fill with

grain and crop material during normal use, however the force of

rocks expelled from the beater will push rocks into the trap.

The rock trap must be emptied daily, more often if harvesting

in rocky conditions.

The balance between optimum rock protection performance

and feeder capacity is determined by the beater speed and

beater blade extension adjustments.

• Rock trap performance is greatest with faster beater speed,

and beater extensions adjusted to the fully extended position

(see figure 13.2)

• Excessive beater speed and blade extension will restrict

crop flow

The beater blades passing rapidly past the feeder form a “wall” that

inhibits the flow of material past the beater, and on to the rotor.

• Beater blade extensions are mounted with slotted holes.

Retracting extensions will allow the greatest material flow,

however rock protection will be reduced.

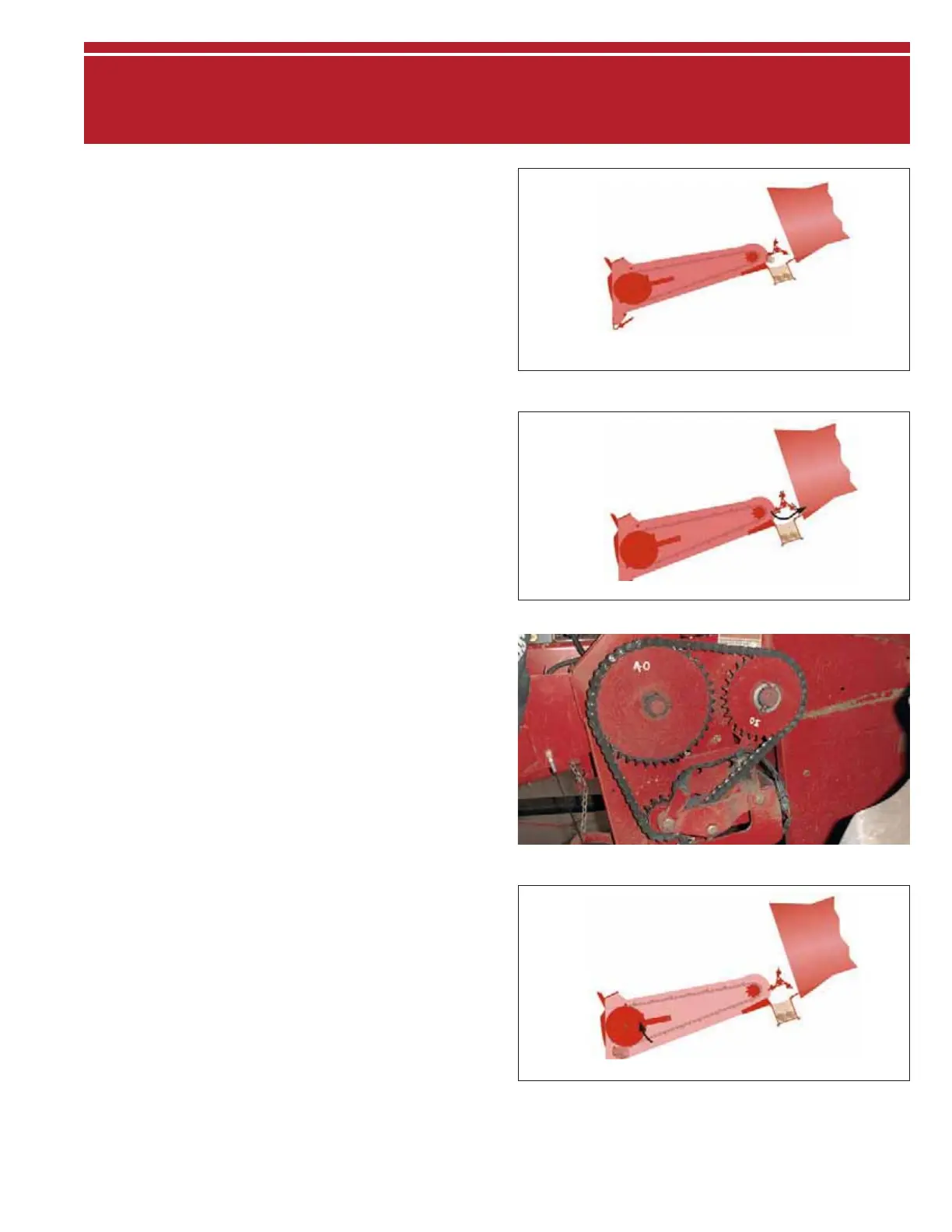

• Sprockets on the left side of the feeder are used to adjust

beater speed. Sprocket combinations are 40 tooth drive

(on feeder shaft) and 20 tooth driven (on beater shaft) for

the fastest beater speed

(see figure 13.3).

• A 30 tooth driven sprocket, and three additional chain links,

are supplied with the combine to allow a slower beater speed

when used with the 40 tooth drive sprocket.

Depending on feeding conditions and the number of rocks that

could potentially be picked up while harvesting, operators need

to make adjustments to speed and blade extension to protect

the combine with minimal impact on feeding performance.

• In tough feeding conditions or material wrapping, such as

a high degree of green stems, serrated blade extensions can

be ordered and installed on the beater to improve feeding

aggressiveness

• Lower beater speeds will also reduce the incidence

of wrapping

The feeder drum with stone retarder should be allowed to float

on combines equipped with a rock trap.

• The stone retarder drum is intended to stop the feeder if

rocks are encountered that are too large for the rock trap

(see figure 13.4)

• Smaller rocks should be allowed to enter the feeder, and are

caught in the rock trap

• Setting stops to hold the drum in the down position will

impair feeding performance

Figure 13.1

Figure 13.2

Figure 13.3

Figure 13.4

Loading...

Loading...