GENERAL MAINTENANCE

9

Hydraulic System (cont.) “What’s with the Color of the

Oil in My New Combine?”

The Hy-Tran fluid and the engine oil shipped in new combines

is dyed to allow easier detection of leaks.

Replacement oils are not dyed. Follow recommended change

intervals for the original fluids, and do not replace fluid because

it is the “wrong color”.

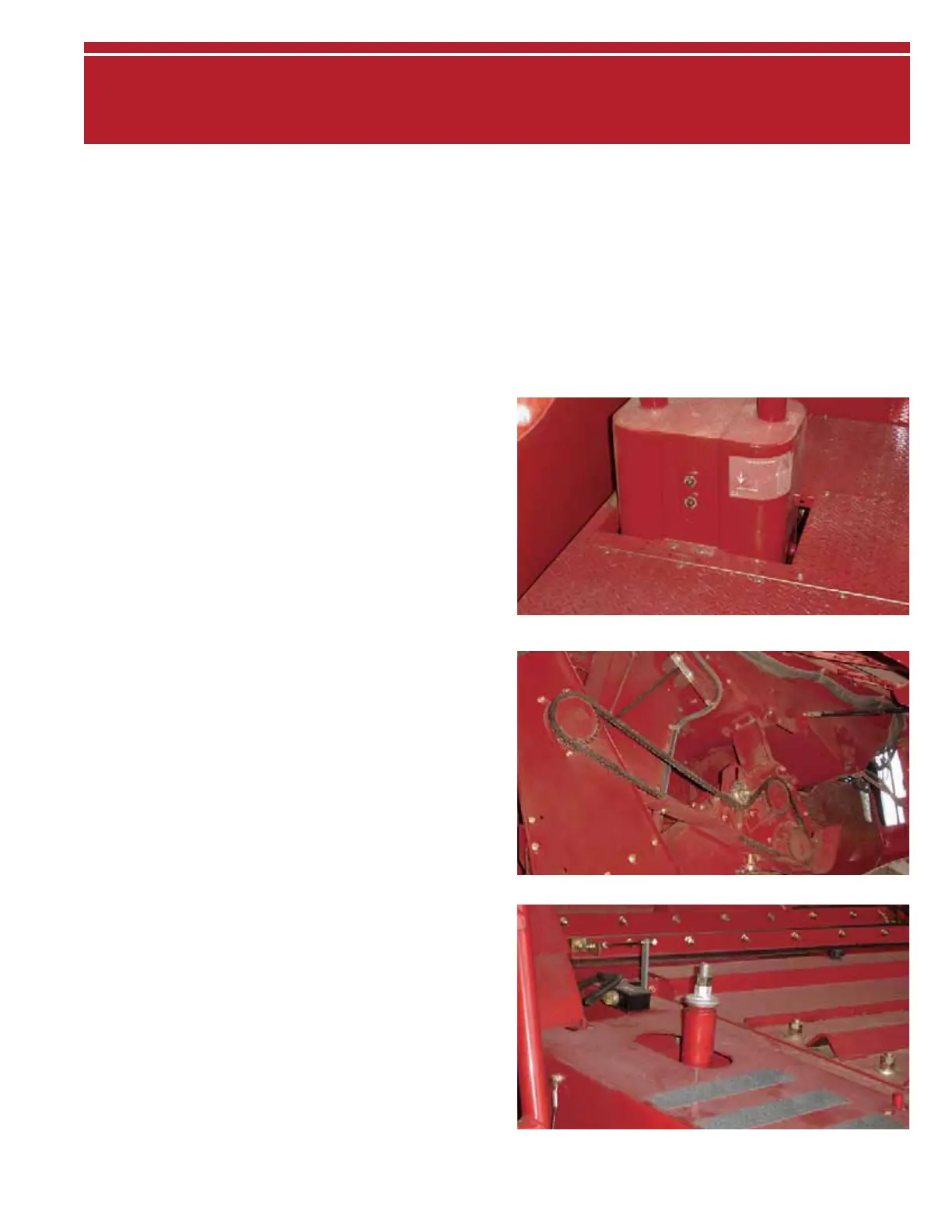

Roller Chain

Drive chains work hard on a combine, and proper maintenance

is crucial for reliable operation. Most important, consult the

Operator’s Manual for tension adjustments and specifications

(see figure 9.2).

• Insufficient tension allows chains to whip during operation,

placing shock loads on the chain, sprockets, shafts,

and bearings

• Loose chains do not transmit power at a consistent speed,

and in extreme cases can slip or jump off sprockets

• Excessive tension places added load on the chains,

sprockets, and associated parts

• Chain alignment is critical. Make sure chain is properly

aligned, especially after performing repairs.

• Unless specified, operator choice determines if chains

are lubricated, or run dry. If chains are initially lubricated,

re-lubricate regularly to flush contaminants from the chain

and maintain lubricant protection.

• Use chain lubricant formulated to cling to the chains,

providing longer lasting protection with less oil spray onto

the machine

Belts

The same basic standards apply to belts, as chains. Follow

specified tension adjustments to promote long belt life and

efficient operation

(see figure 9.3).

• Avoid overstressing components with excessive tension

• Inadequate tension allows belts to slip, accelerating wear

and adversely affecting performance

• Belt alignment and tension not properly maintained may

result in slippage, uneven wear, and poor tracking

• Alignment is particularly important with multi-vee and

poly-vee belts. Uneven loading will affect belt life and

efficiency if improperly aligned.

Bearings

Be sure to keep weeds and crop residue from wrapping on

shafts near bearings.

• If the material starts to create a drag on the seal it could

damage the seal and allow moisture and debris to enter

the bearing, and lubrication to escape. The seal failure will

ultimately lead to a bearing failure.

• Always follow the lubrication schedules in the Operator’s

Manual. Over-greasing will also damage seals, and shorten

bearing life.

Figure 9.1

Figure 9.2

Figure 9.3

Loading...

Loading...