ENGLISH

11

29

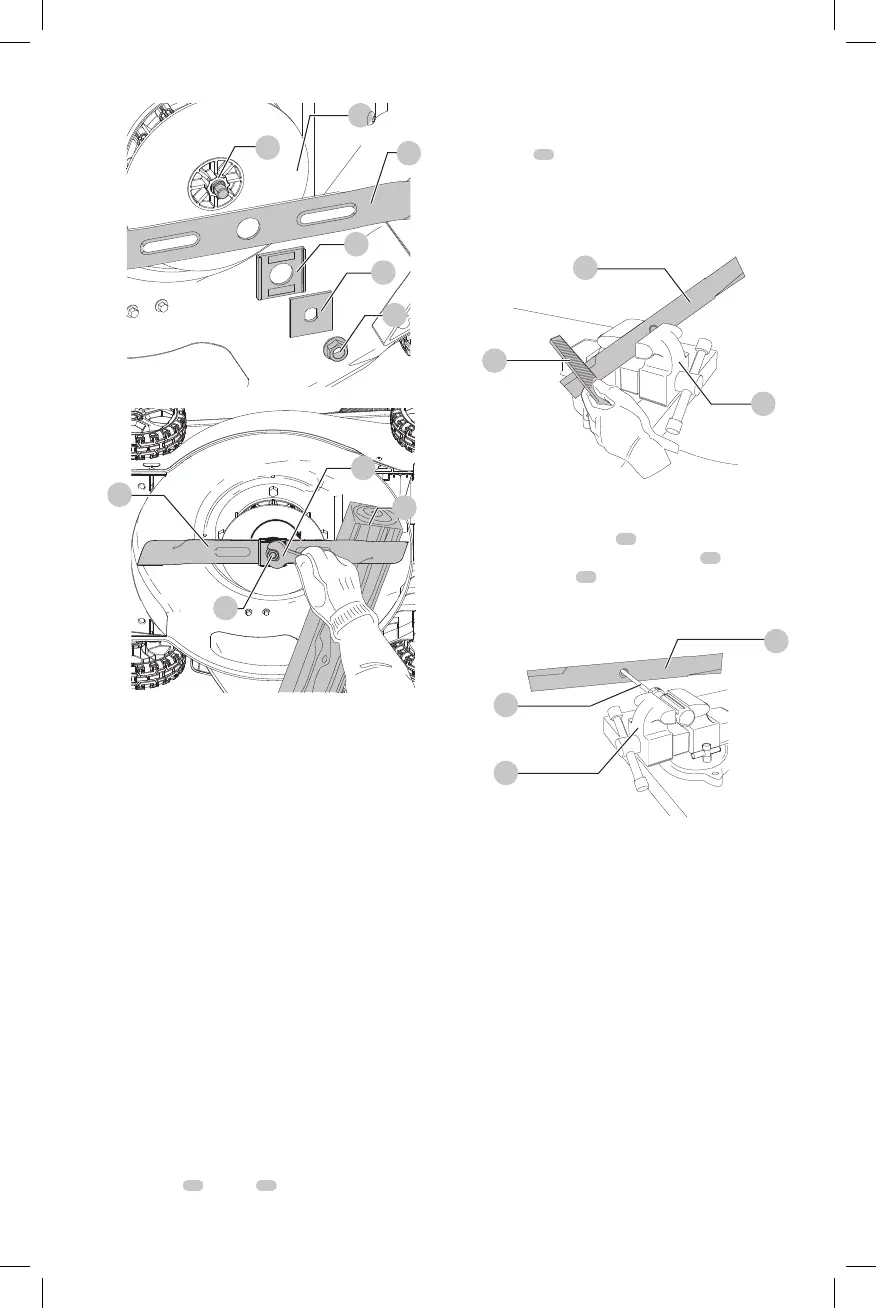

Fig.K

30

28

27

26

24

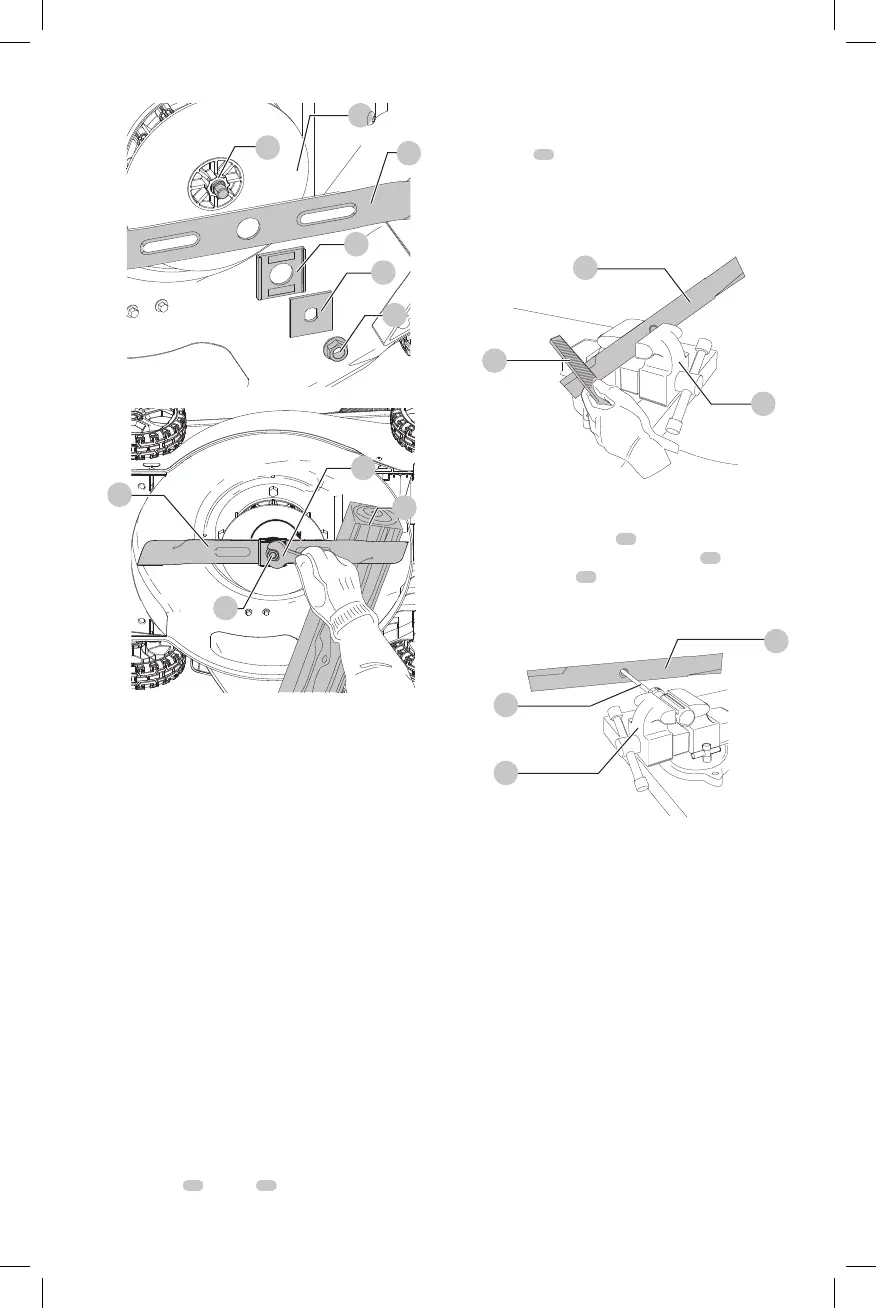

Fig.L

28

23

25

24

Blade Sharpening

KEEP BLADE SHARP FOR BEST MOWER PERFORMANCE. A

DULL BLADE DOES NOT CUT GRASSCLEANLY.

WARNING: Use gloves and proper eye protection

while removing, sharpening, and installing blade.

Ensure that safety key and battery pack are removed.

Sharpening the blade twice during a mowing season is

usually sufficient under normal circumstances. Sand causes

the blade to dull quickly. If your lawn has sandy soil, more

frequent sharpening may berequired. REPLACE BENT OR

DAMAGED BLADEIMMEDIATELY.

When Sharpening the Blade

• Make sure blade remainsbalanced.

• Sharpen blade at the original cuttingangle.

• Sharpen cutting edges on both ends of blade, removing

equal amounts of material from bothends.

To Sharpen Blade in a Vise (Fig. M)

1. Be sure the bail handle is released, the blade has

stopped and safety key and battery pack are removed

before removing theblade.

2. Remove blade from mower. See instructions for

Removing and InstallingBlade.

3. Secure blade

28

in a vise

31

.

4. Wear proper eye protection and gloves and be careful

not to cutyourself.

5. Carefully file the cutting edges of the blade with a fine

tooth file

32

or sharpening stone, maintaining the

angle of the original cuttingedge.

6. Check balance of blade. See instructions for

BladeBalancing.

7. Replace blade on mower and tightensecurely.

Fig. M

31

28

32

Blade Balancing (Fig. N)

Check balance of the blade

28

by placing center hole in

the blade over a nail or round screwdriver

33

, clamped

horizontally in a vise

31

. If either end of the blade rotates

downward, file along the sharp edge of that dropping end.

Blade is properly balanced when neither enddrops.

Fig. N

28

31

33

Lubrication

No lubrication is necessary. Do not oil the wheels. They have

plastic bearing surfaces which require nolubrication.

Cleaning (Fig. A)

WARNING: Blow dirt and dust out of all air vents

with clean, dry air at least once a week. To minimize

the risk of eye injury, always use ANSI Z87.1 (CAN/

CSA Z94.3) approved eye protection and NIOSH/

OSHA/MSHA approved respiratory protection when

performingthisprocedure.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic

materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool

into aliquid.

Loading...

Loading...