17Section 6 — Maintenance & adjuStMentS

6. If adding only a few ounces of gear oil, use API rated GL-4

7. While checking frequently to avoid overfilling, slowly add

gear oil into the oil fill hole until it reaches the halfway

point on the drive shaft.

8. Securely replace the oil fill plug.

Lubrication

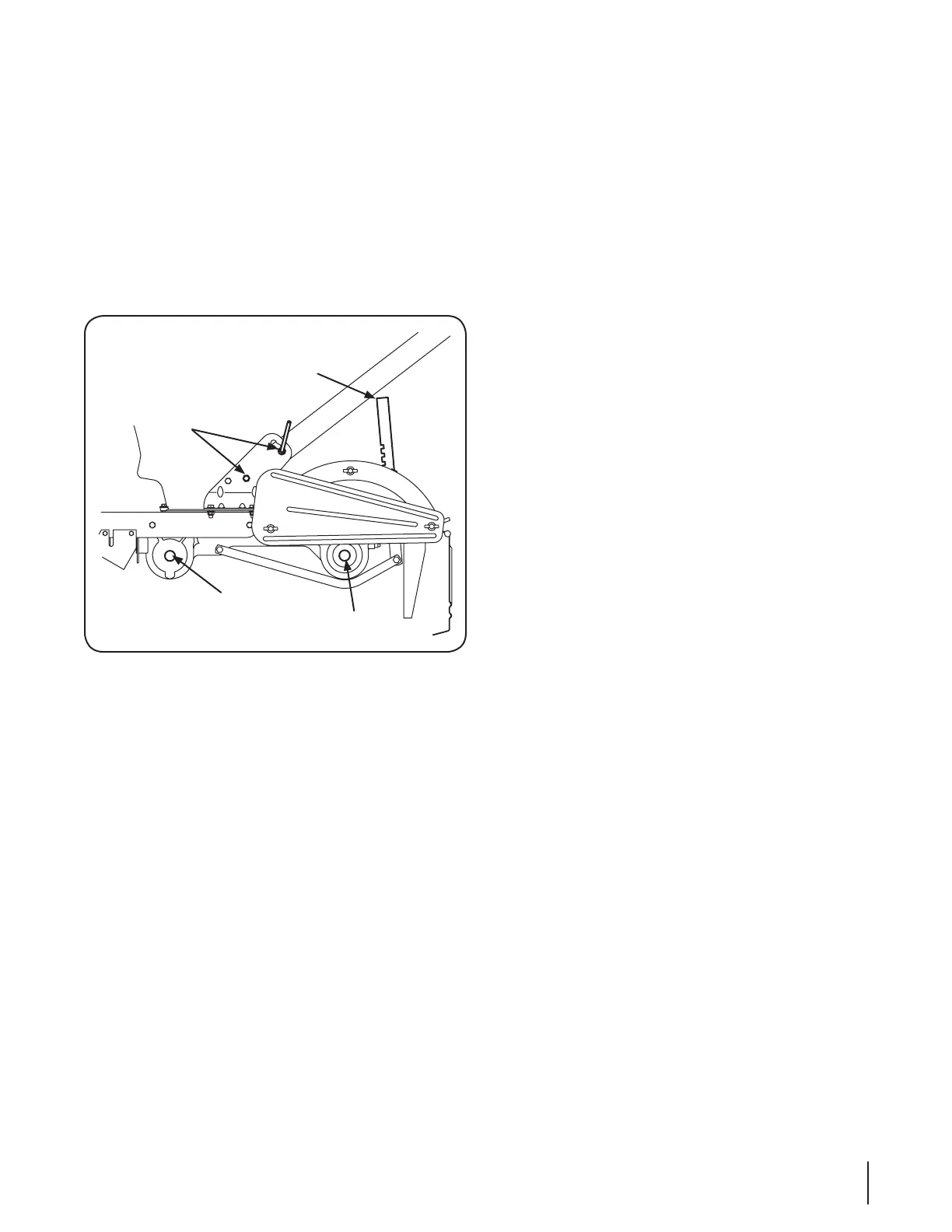

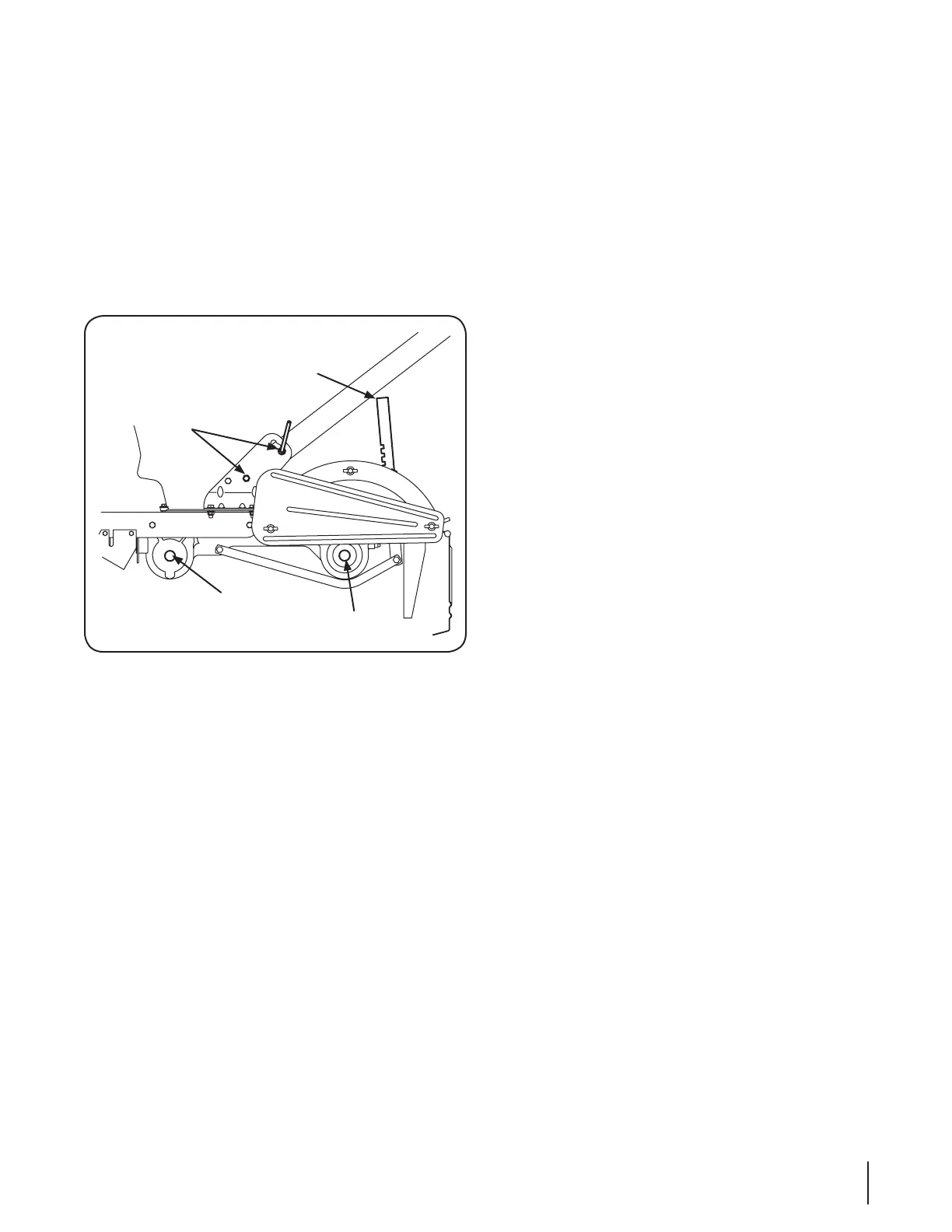

points shown in Fig. 6-2 and described below.

Handlebar Hardware

Depth Regulator Lever

Wheel Shaft

Tine Shaft

Figure 6-2

and clean general purpose grease (grease containing a metal

lubricant is preferred, if available).

Remove the wheels, clean the wheel shaft and apply a thin

coating of grease.

Grease the back, front and sides of the depth regulator

lever.

Remove the tines and clean the tine shaft. Use a file or

sandpaper to gently remove any rust, burrs or rough spots

(especially around the holes in the shaft). Apply grease to

the ends of the shaft before installing the tines.

and the handlebar attaching screws.

Off-Season Storage

for storage as follows:

Clean the tiller and engine.

2. Do routine tiller lubrication and check for loose parts and

hardware.

Protect the engine and perform the recommended engine

maintenance by following the storage instructions found

fuel lines, carburetor and fuel tank from gum deposits

by removing fuel or by treating fuel with a fuel stabilizer

(follow the engine maintenance recommendations).

4. Store the tiller in a clean, dry area.

5. Never store the tiller with fuel in the fuel tank in an

enclosed area where gas fumes could reach an open flame

or spark, or where ignition sources are present (space

heaters, hot water heaters, furnaces, etc.).

Loading...

Loading...