4 Instructions RI8PG202 © Danfoss 02/2014 AK-CC 250A

1 2 3 4 5 6 7 8 9 10

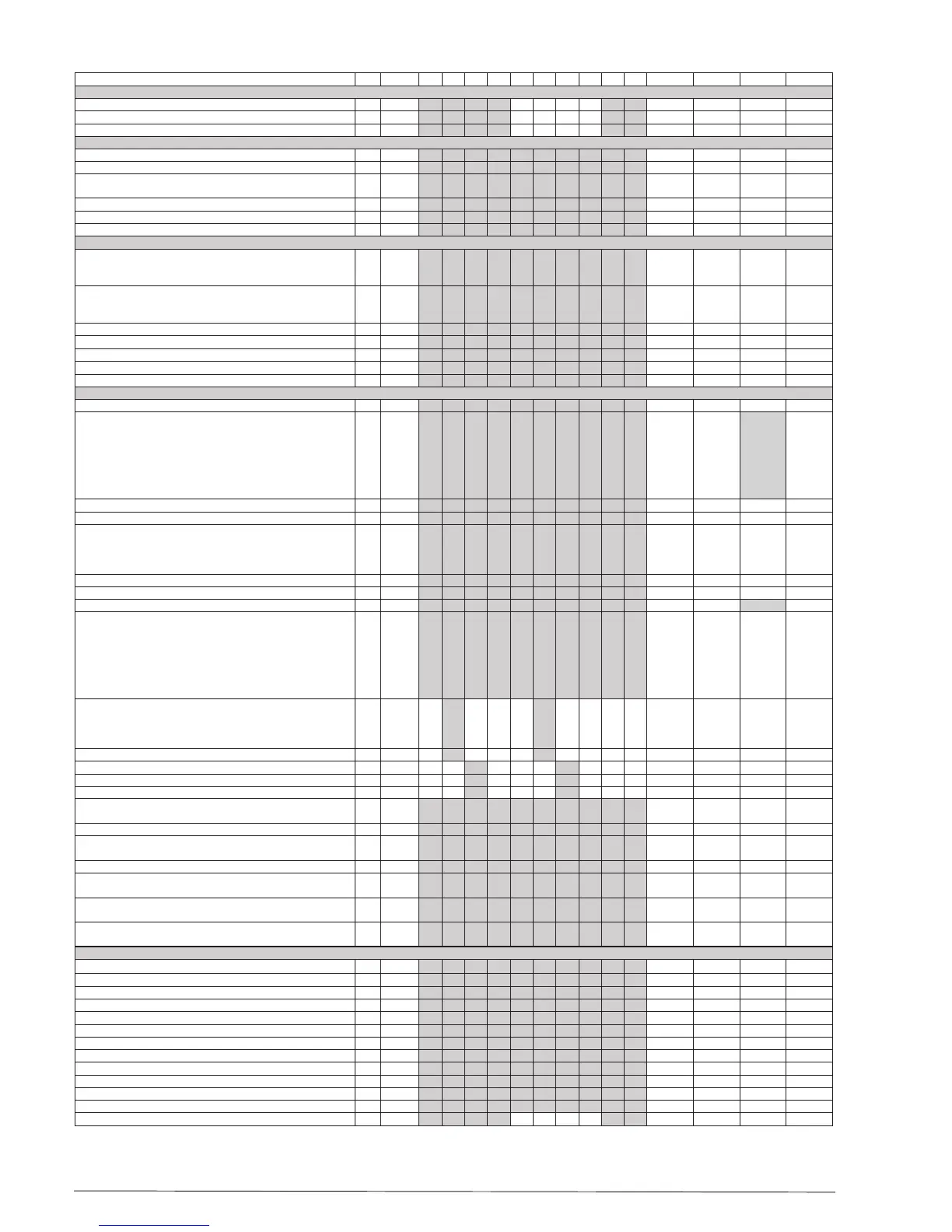

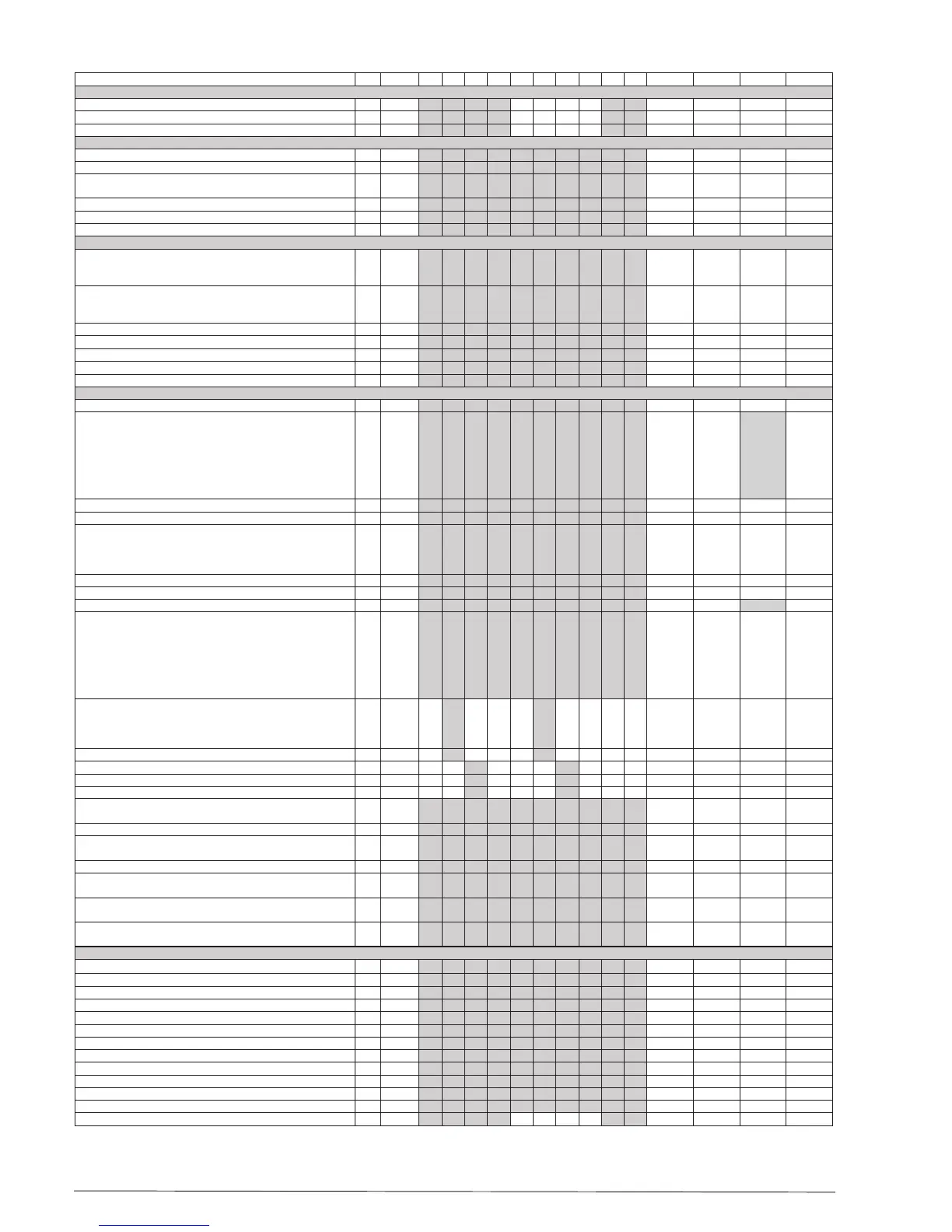

Fan

Fan stop at cutout compressor F01 no yes no

Delay of fan stop F02 0 min 30 min 0 min

Fan stop temperature (S5) F04 -50.0°C 50.0°C 50.0°C

HACCP

Actual temperature measurement for the HACCP function h01

Last registered peak temperature h10

Selection of function and sensor for the HACCP function. 0 = no

HACCP function. 1 = S4 used (maybe also S3). 2 = S5 used

h11 0 2 0

Alarm limit for the HACCP function h12 -50.0°C 50.0°C 8.0°C

Time delay for the HACCP alarm h13 0 min. 240 min. 30 min.

Select signal for the HACCP function. S4% (100% = S4, 0% = S3) h14 0% 100% 100%

Real time clock

Six start times for defrost.

Setting of hours.

0=OFF

t01-t06 0 hours 23 hours 0 hours

Six start times for defrost.

Setting of minutes.

0=OFF

t11-t16 0 min 59 min 0 min

Clock - Setting of hours *** t07 0 hours 23 hours 0 hours

Clock - Setting of minute *** t08 0 min 59 min 0 min

Clock - Setting of date *** t45 1 31 1

Clock - Setting of month *** t46 1 12 1

Clock - Setting of year *** t47 0 99 0

Miscellaneous

Delay of output signals after start-up o01 0 s 600 s 5 s

Input signal on DI1. Function:

0=not used. 1=status on DI1. 2=door function with alarm when

open. 3=door alarm when open. 4=defrost start (pulse-pres-

sure). 5=ext.main switch. 6=night operation 7=change refer-

ence (activate r40). 8=alarm function when closed. 9=alarm

function when open. 10=case cleaning (pulse pressure).

11=forced cooling at hot gas defrost.

o02 1 11 0

Network address (0=o) o03 0 240 0

Access code 1 (all settings) o05 0 100 0

Used sensor type. See page 6.

Pt: Pt 1000 Ω @ 0°C

P01: PTC 1000 Ω (nominal 990 Ω) = EKS 111

P02: PTC 1000 Ω @ 25°C (nominal 1000 Ω)

o06 Pt P02 Pt

Display step = 0.5 (normal 0.1 at Pt sensor) o15 no yes no

Max hold time after coordinated defrost o16 0 min 60 min 20

Select signal for display view. S4% (100%=S4, 0%=S3) o17 0% 100% 100%

Input signal on DI2. Function:

(0=not used. 1=status on DI2. 2=door function with alarm when

open. 3=door alarm when open. 4=defrost start (pulse-pres-

sure). 5=ext. main switch 6=night operation 7=change refer-

ence (activate r40). 8=alarm function when closed. 9=alarm

function when open. 10=case cleaning (pulse pressure).

11=forced cooling at hot gas defrost.). 12=coordinated defrost)

o37 0 12 0

Conguration of light function (relay 4)

1=ON during day operation. 2=ON / OFF via data communica-

tion. 3=ON follows the DI-function, when DI is selected to door

function or to door alarm

o38 1 3 1

Activation of light relay (only if o38=2) o39 OFF ON OFF

Rail heat On time during day operations o41 0% 100% 0

Rail heat On time during night operations o42 0% 100% 0

Rail heat period time (On time + O time) o43 6 min 60 min 10 min

Case cleaning. 0=no case cleaning. 1=Fans only. 2=All output

O.

*** o46 0 2 0

Selection of EL diagram. See overview page 2 * o61* 1 10 1

Download a set of predetermined settings. See overview

previous page.

* o62* 0 6 0

Access code 2 (partly access) *** o64 0 100 0

Save the controllers present settings to the programming key.

Select your own number.

o65 0 25 0

Load a set of settings from the programming key (previously

saved via o65 function)

o66* 0 25 0

Replace the controllers factory settings with the present set-

tings

o67 OFF On OFF

Service

Status codes are shown on page 5 S0-S33

Temperature measured with S5 sensor *** u09

Status on DI1 input. on/1=closed u10

Temperature measured with S3 sensor *** u12

Status on night operation (on or o) 1=closed *** u13

Temperature measured with S4 sensor *** u16

Thermostat temperature u17

Read the present regulation reference u28

Status on DI2 output. on/1=closed u37

Temperature shown on display u56

Measured temperature for alarm thermostat u57

Status on relay for cooling ** u58

Status on relay for fan ** u59

Loading...

Loading...