Voltage [V] Minimum waiting time (minutes)

4 7 15 20 30 40

200–240 0.25–3.7 kW

(0.34–5 hp)

–5.5–37 kW

(7.5–50 hp)

380–500 0.25–7.5 kW

(0.34–10 hp)

– 11–75 kW

(15–100 hp)

90–200 kW

(150–350 hp)

250–500 kW

(450–750 hp)

250–800 kW

(450–1350 hp)

315–500

(500–750 hp)

400 – – – 90–315 kW

(125–450 hp)

––

500 – – – 110–355 kW

(150–450 hp)

––

525 – – – 55–315 kW

(75–400 hp)

––

525–600 0.75–7.5 kW

(1–10 hp)

– 11–75 kW

(15–100 hp)

–––

525–690 – 1.5–7.5 kW

(2–10 hp)

11–75 kW

(15–100 hp)

37–315 kW

(50–450 hp)

355–1200 kW

(450–1550 hp)

355–2000 kW

(450–2050 hp)

355–710 kW

(400–950 hp)

690 – – – 55–315 kW

(75–400 hp)

––

Table 1.4 Discharge Time, VLT

®

AutomationDrive FC 301/FC 302

Voltage [V] Minimum waiting time (minutes)

415

380–480 0.25–7.5 kW

(0.34–10 hp)

11–75 kW

(15–100 hp)

Table 1.5 Discharge Time, VLT

®

Lift Drive, LD 302

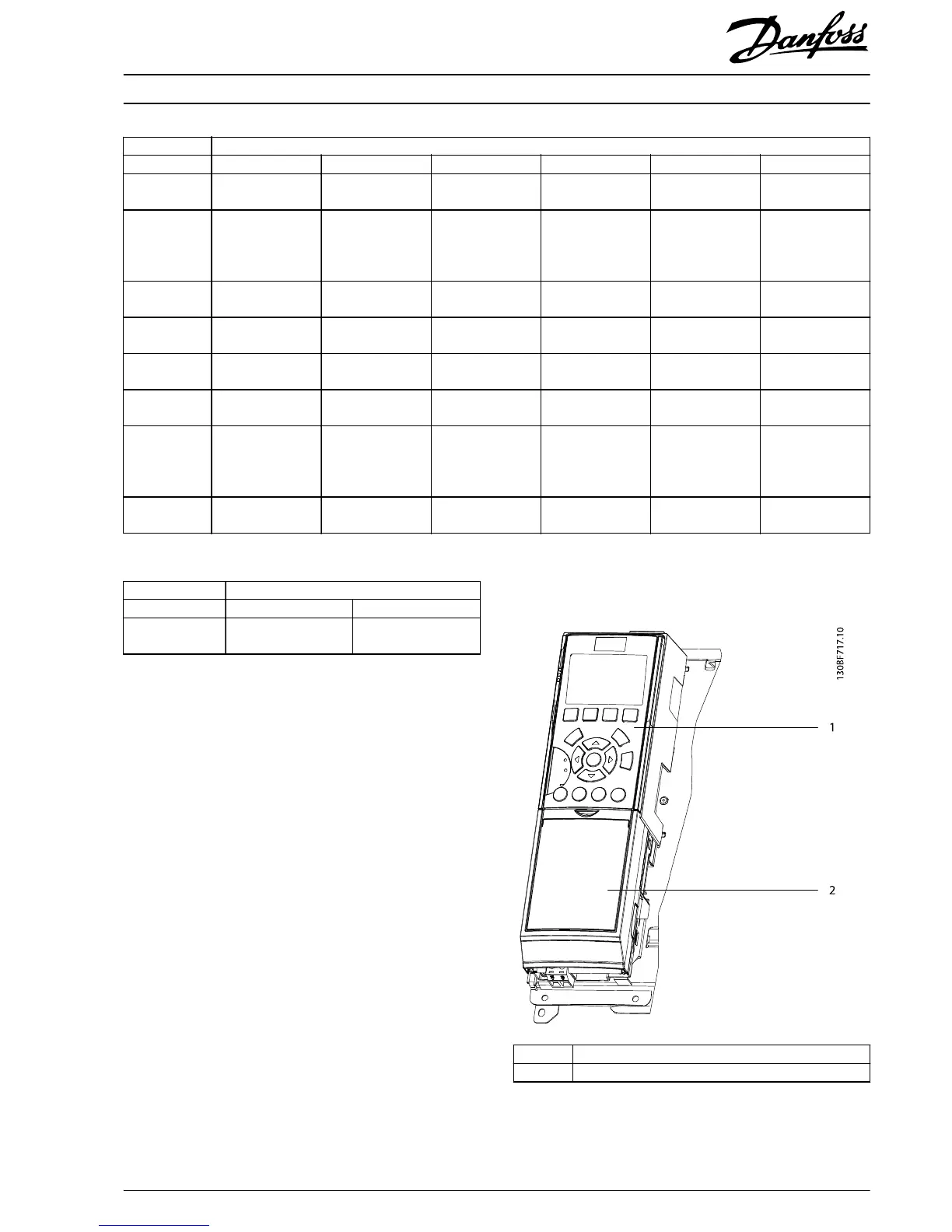

Item Supplied

The following item is supplied:

•

Control card

Tools

Only 2 tools are required for replacing the control card.

•

Torx 10 screwdriver

•

Flat-head screwdriver

Additional Items Required

•

VLT

®

frequency converter

Replacing the Control Card

1LCP

2Blind cover

Illustration 1.1 LCP and Blind Cover

Installation Instructions

Control Card VLT

®

FC Series

MI93A102 Danfoss A/S © 03/2017 All rights reserved.

3

Loading...

Loading...