1

3

4

5

6

7 8

2

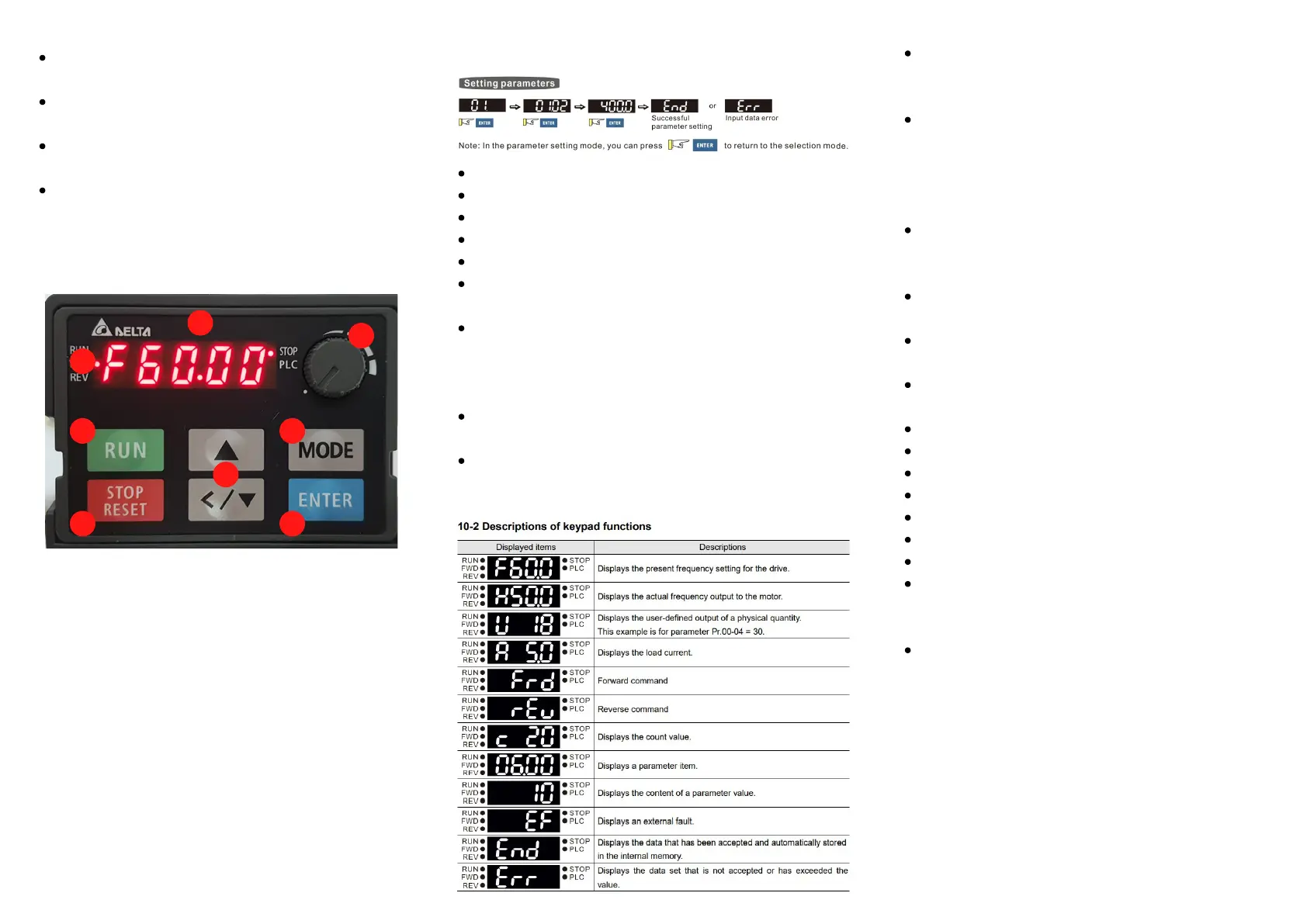

F60.0 will be displayed on the screen.

Press the enter button.

00. will appear on the screen.

Press enter again.

00.00 will appear on the screen.

Use the up and down keys to change parameters

selections to the desired one. Press "ENTER"

You will now be able to change the parameter to the

desired value or setting. Press enter. End will flash

on your screen to indicate that your setting has

been saved.

Continue the above steps till all of your parameters

have been set.

Once all the parameters have been set press the

"MODE" button till the F50.0 screen comes up again.

00.02 All parameters are reset to factory settings

for 50Hz, set to 9 (must be none after initial power

up)

00.20 Source of master Frequency Command.

00.21 Source of master Operation Command.

01.00 Change to the maximum Frequency

required

01.01 Change value to match Hz on motor name

plate

01.02 Change to match voltage on motor name

plate (Max Voltage output)

01.10 Upper limit Frequency

01.11 Lower limit Frequency

01.12 Acceleration time (factory setting 10sec)

01.13 Deceleration time (factory setting 10sec)

05.01 Set to Motor Name Plate Current

05.02 Set to Motor Name Plate kW

05.03 Set to Motor Name Plate Speed (rpm)

05.04 Set as the number of poles of the

motor(3000rpm=2pole; 1500rpm=4pole;

1000rpm=6pole; 750rpm=8pole)

05-00 Auto tuning, option 1 Dynamic test for

induction motor = 1 (note motor must be

unloaded), Static test for induction motor = 2,

after the parameter number is entered press

MODE button to return to main screen showing

F30.00 or F33.33, press the RUN button to start

auto tune, these test should only be preformed

after all the above data is entered.

List of quick set parameters

0 = UP/DOWN arrow (Factory setting)

2 = External analog input

3 = External UP/DOWN terminals

7 = Digital keypad potentiometer

0 = Digital keypad (Factory setting )

1 = External terminals

See back page for remote control set up

Wiring and connection must be carried out by

a registered electrician.

Connection by an unqualified person voids

the warranty.

Please check the suitability of the motor

before attempting to connect it to the device.

Ensure the motor terminals are configured to

suit supply from VSD, for 1ph supply VFD the

motor must be connected in DELTA. For 3ph

supply VFD please consult the motors name

tag for 400V connection.

Important Notice

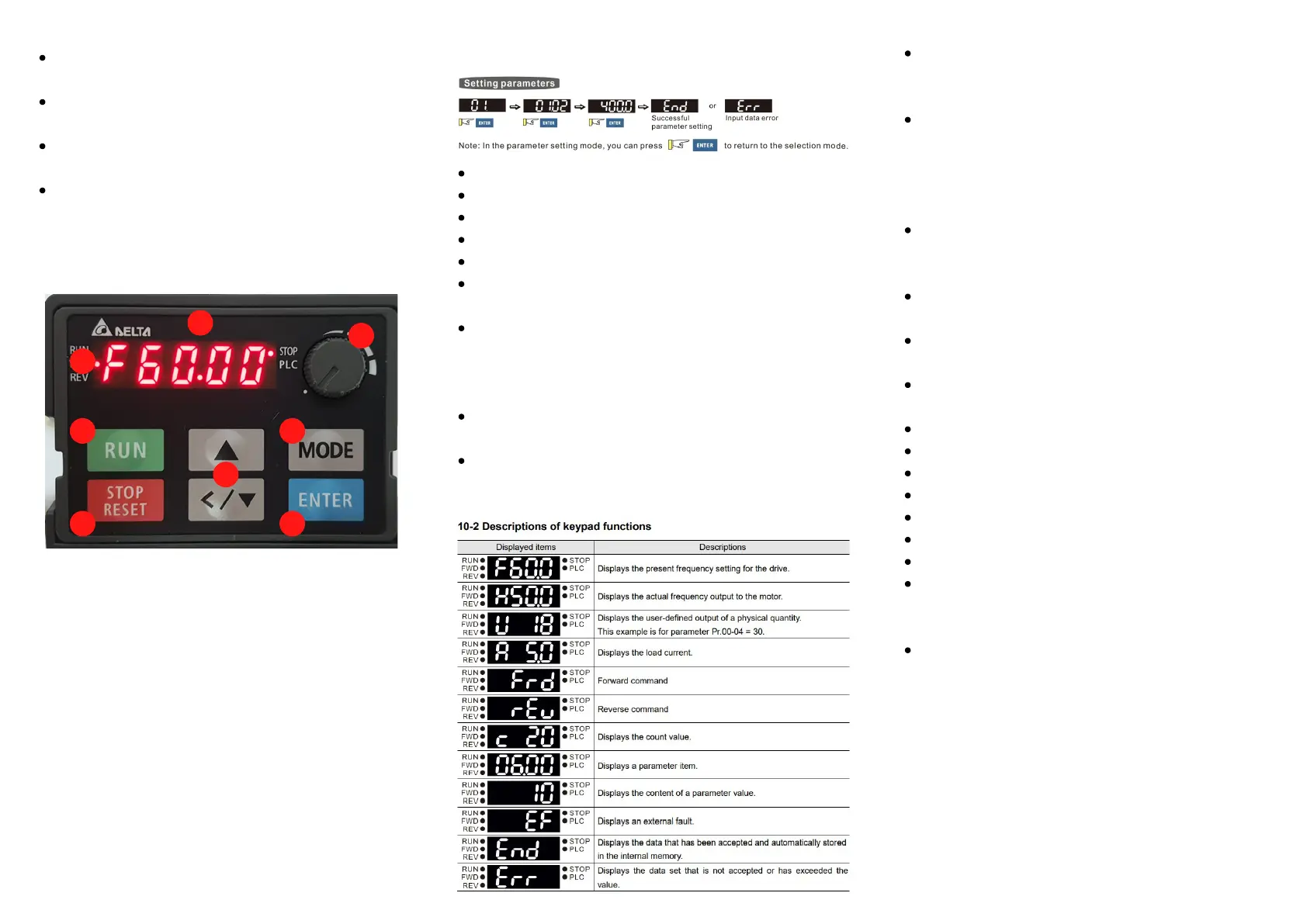

Status Display –Display the drives current status

LED Display—Indicates frequency, voltage, current,

user defined units

Potentiometer—For local frequency control

Run Key— to start drive locally

UP & DOWN Key—Used to change numerical

numbers, frequency, parameters

Mode—Change between different display mode

STOP/RESET— Stops AC drive operation and

resets the drive after a fault has occurred

ENTER - Used to enter and save the parameters

1.

2.

3.

4.

5.

6.

7.

8.

Quick Setup for Variable Speed Drive

Turn on power to unit and follow as below:

FOR ADVANCED SET UP REFFER TO THE FULL

MANUAL

www.rotatingmachinery.co.nz/products/drives

Loading...

Loading...