ENGLISH

8

OPERATION

WARNING: To reduce the risk of serious personal injury, turn unit off and disconnect

it from power source before making any adjustments or removing/installing

attachments or accessories. An accidental start-up can causeinjury.

The riving knife provided with this saw is marked as follows:

.063” (1.6mm) THICK RIVING KNIFE. ONLY FOR USE WITH 8-1/4” (210mm) BLADE WITH .071”

(1.8mm) MIN KERF WIDTH AND .055” (1.4mm) MAX BODYTHICKNESS.

Blade body thickness and kerf width dimensions for all

table saw blades are available at

www.dewalt.com

If a different blade is used and the body thickness and kerf width dimensions are not provided,

use the following procedure to determine the correct riving knife thickness:

1. Measure the body thickness of theblade.

2. Make a shallow cut in scrap material and measure the kerfwidth.

3. Select the riving knife

21

.

4. Slide the riving knife through the shallow cut made in step 2 to confirm the correct riving

knife has been selected. The riving knife should not bind or drag through thecut.

WARNING: If any dragging or binding of the material is encountered as it reaches the riving

knife, turn unit off and disconnect machine from power source. Repeat steps 1–4 to make the

proper riving knife selection before attempting anothercut.

Kickback

Kickback is a dangerous condition! It is caused by the workpiece binding against the blade. The

result is that the workpiece can move rapidly in a direction opposite to the feed direction. During

kickback, the workpiece could be thrown back at the operator. It can also drag the operator’s

hand back into the blade if the operator’s hand is at the rear of the blade. If kickback occurs, turn

the saw OFF and verify the proper functioning of the riving knife, anti-kickback assembly and

blade guard assembly before resumingwork.

WARNING: See Additional Safety Rules for Table Saws and follow all warnings

provided regardingKICKBACK.

WARNING: Before using the saw, verify the following each and every time:

• ALWAYS wear proper eye, hearing and respiratoryequipment.

• Blade is securelytightened.

• Bevel angle and rail lock levers arelocked.

• If ripping, ensure that rip fence locked lever is locked and that the fence is parallel to

theblade.

• If crosscutting, miter gauge knob is securelytightened.

• The blade guard assembly is properly attached and the anti-kickback assembly

isfunctioning.

• ALWAYS inspect the blade guard assembly and riving knife for proper alignment,

operation and clearance with sawblade.

• ALWAYS make sure both guards are in the down position in contact with the table

beforeoperating.

WARNING: To reduce the risk of serious personal injury, have push stick ready to use before

startingcut.

Failure to adhere to these common safety rules can greatly increase the likelihood ofinjury.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the blade guard assembly and riving knife for proper operation alignment

and clearance with saw blade. Personal injury may result.

WARNING: Ripping or crosscutting may cause saw to tip over while operating. Make sure

saw is securely mounted to a stablesurface.

WARNING: Never use the fence and miter gauge together. This may cause a kickback

condition and injure theoperator.

CAUTION: If this saw makes an unfamiliar noise or if it vibrates excessively, cease operating

immediately, turn unit off and disconnect from power source until the problem has been

located and corrected. Contact a

factory service center, a

authorized

service center or other qualified service personnel if the problem cannot be found.

WARNING: The proper throat plate must be in place at all times to reduce the risk of a

thrown workpiece and possibleinjury.

There are two basic types of cutting with table saws: ripping and crosscutting. Regardless of

material, man made or natural wood, the distinction between ripping and crosscutting is as

follows: Ripping is cutting to a different width (usually with the grain) and crosscutting describes

cutting material across the shorter dimension (usually against the grain).

WARNING: When ripping, always use the fence to provide a guide for the material and blade

guard assembly to protect against a kickbacksituation.

WARNING: Never perform any cutting operation freehand. Never perform plungecutting.

WARNING: When crosscutting, always use the miter gauge. Do not use both the rip fence

and miter gaugetogether.

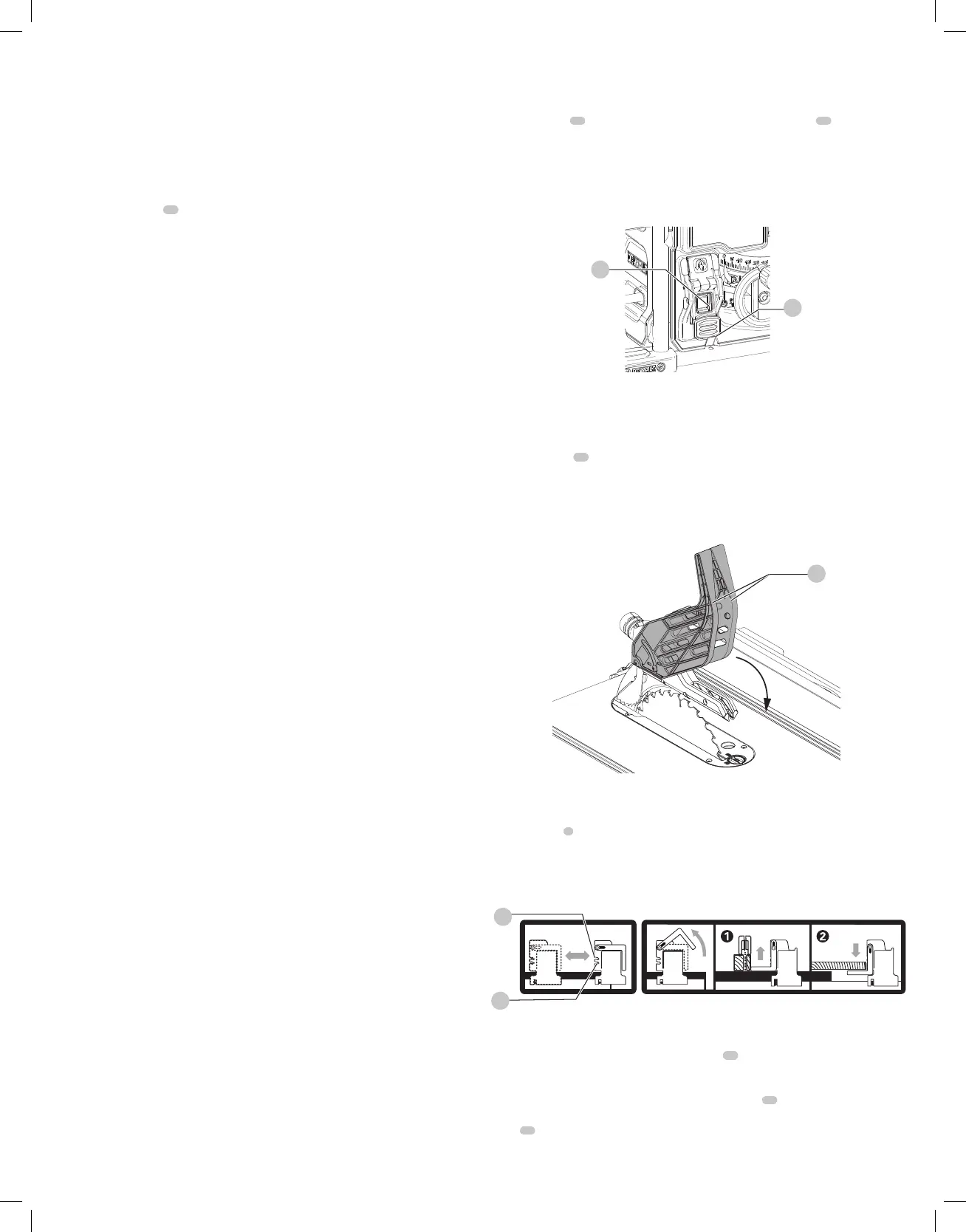

ON/OFF Switch (Fig.O)

WARNING: To reduce the risk of injury, be sure the switch is in the OFF position before

plugging machine in.

Push green button

44

in to turn this saw on and push down the red paddle

46

to turn this

sawoff.

Lock Off Feature Instructions

A cover above the switch folds down for insertion of a padlock to lock the saw off. A padlock

with a maximum diameter of 1/4"(6.35mm) and minimum clearance of 3" (76.2 mm) is

recommended.

44

46

Fig. O

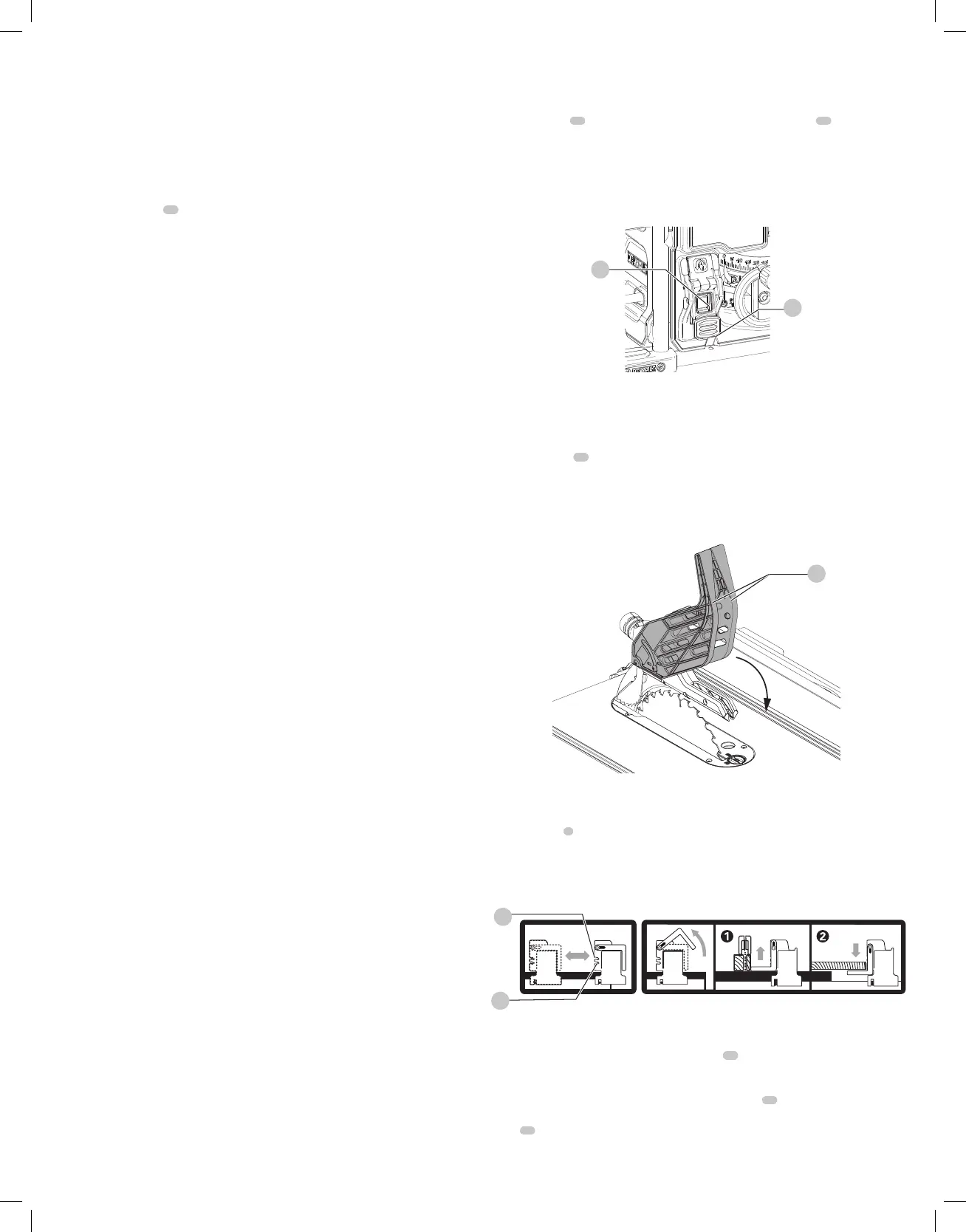

Guard Operating Feature (Fig.P)

WARNING: To reduce the risk of serious personal injury, turn unit off and disconnect

it from power source before making any adjustments or removing/installing

attachments oraccessories. An accidental start-up can causeinjury.

1. The guard arms

48

will lock in place when in the raisedposition.

2. This feature improves visibility when measuring the blade to fencedistance.

3. Push down on guard(s) and they will release to the operatingposition.

NOTE: Pull on the anti-kickback assembly to ensure it is locked inplace.

ALWAYS make sure both guards are in the down position in contact with the table

beforeoperating.

Fig. P

48

Rip Fence Operation (Fig. A,Q)

Rail Lock Lever (Fig. A)

The rail lock lever

5

locks the fence in place preventing movement during cutting. To lock the

rail lever, push it down and toward the rear of the saw. To unlock, pull it up and toward the

front of thesaw.

WARNING: When ripping, always lock the rail locklever.

Fig. Q

50

49

Work Support Extension/Narrow Ripping Fence (Fig. A, Q)

The table saw is equipped with a narrow ripping fence

18

that also supports work that extends

beyond the sawtable.

To use the narrow ripping fence in the work support position, rotate it from its stored position as

shown in Figure Q, and slide the pins into the lower sets of slots

49

on both ends of thefence.

To use the narrow ripping fence in the narrow ripping position, snap the pins into the upper sets

of slots

50

on both ends of thefence.

This feature will allow 2" (51mm) of extra clearance to the blade. Refer to FigureT.

NOTE: When not in use, the narrow ripping fence should be placed in its storedposition.

Loading...

Loading...