14

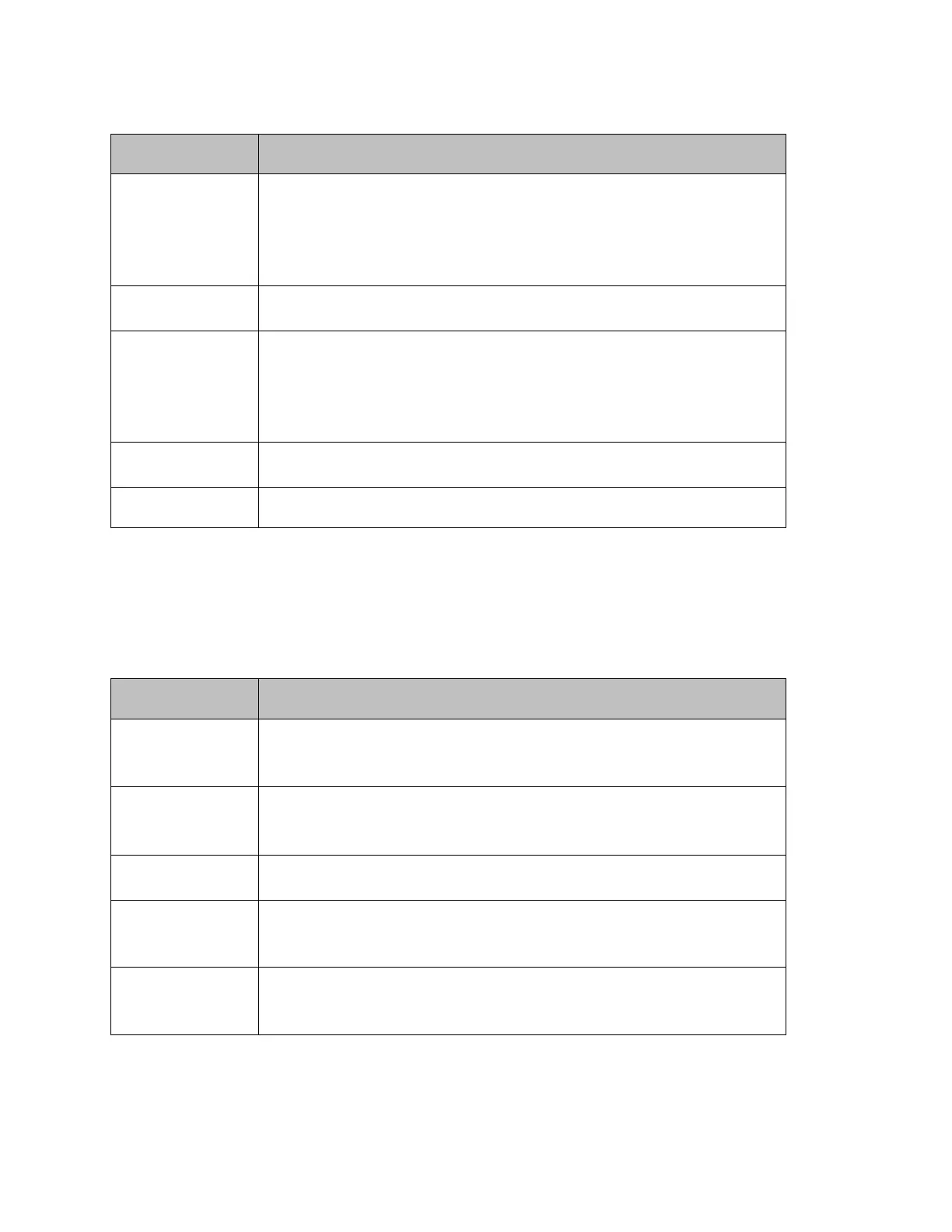

Alarm On — Pump not Operating

Check the voltage at a location nearest the pump, such as the

junction box or electrical quick disconnect (EQD) plug. The correct

voltage is listed on the pump nameplate. Note: Voltage must be

within 10 percent of nameplate voltage (240V: 216 to 264V; 120V:

108V to 132V). 208V requires a transformer to boost voltage.

Check the Equalizer Tube connected to the Equalizer and make

sure that it isn't crimped or pinched.

Check the tank for sufficient fluid to activate the alarm. Insufficient

fluid may indicate a problem with the alarm wiring, the alarm

sensing line or the alarm switch. Chapter 9 – Level Sensor and

Chapter 10 Control Cavity, describes the process for checking the

alarm wiring and controls.

Inspect the electrical controls. Replace any wet or corroded

controls. See Chapter 10 – Control Cavity.

Test the controls as described in Chapter 10 – Control Cavity

Table 3 – 8

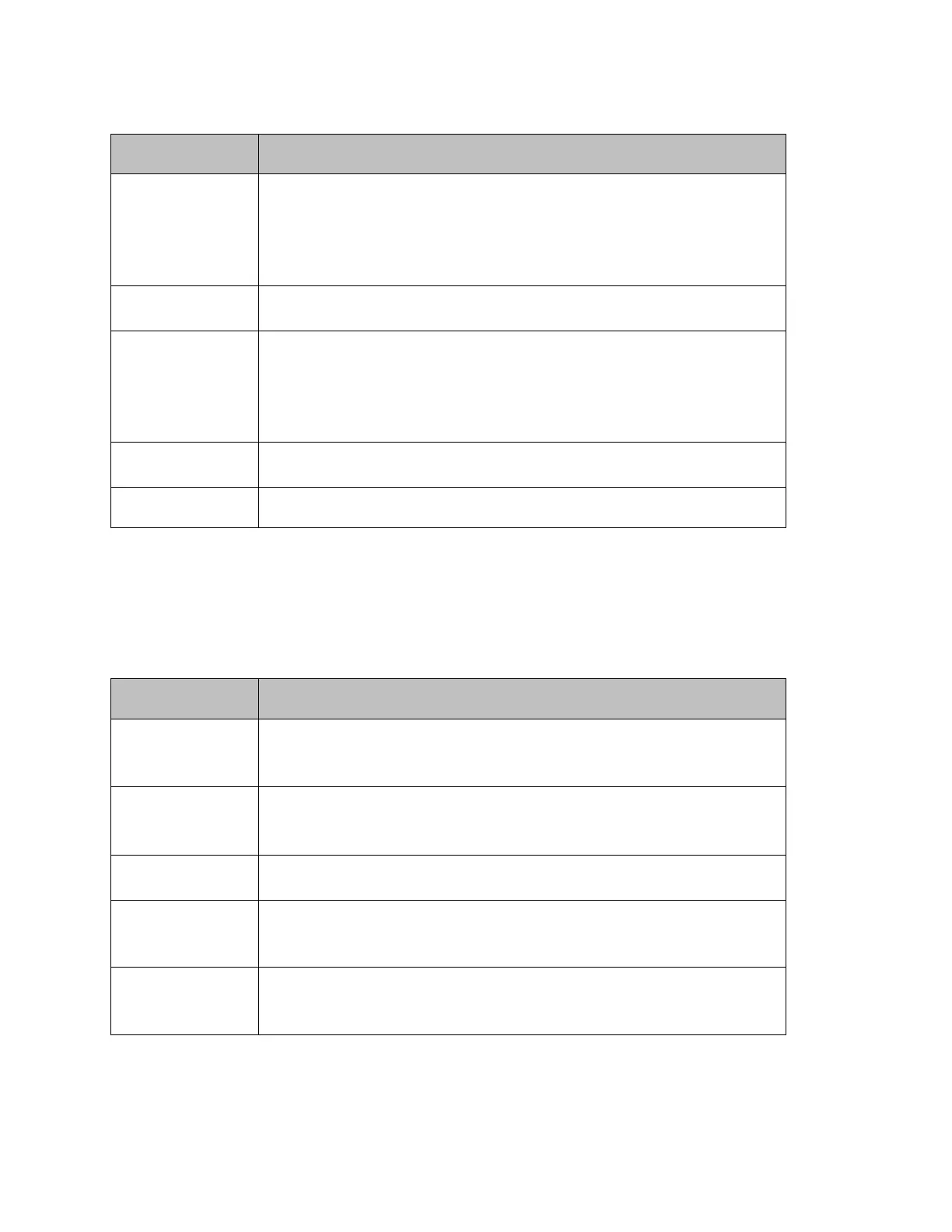

Alarm Activates Frequently

The incoming flow is greater than the pump can handle. Infiltration,

a sump pump, a hot tub or any other device that causes excessive

water flow can cause high flow.

Plugged Vent or

Equalizer Tube

Check the Vent and the Equalizer Tube. A plugged or partially

plugged Vent or Equalizer Tube may cause the alarm to activate

frequently. Replace the Equalizer Tube if kinked or damaged.

Pull the pump out of the tank. Inspect the Level Sensors for leaks

and debris; use Level Sensor test to check for leaks.

Line Blockage or

Worn Stator

Check the amperage. If the amperage is high, look for a line

blockage. If the amperage is low, inspect the Stator for excessive

wear.

Check the Tray Cable wiring for cuts, breaks and shorts. Use a

Megohm Meter to check for shorts between each pair of leads.

Replace the Tray Cable if a short is found.

Table 3 – 9

Loading...

Loading...