30

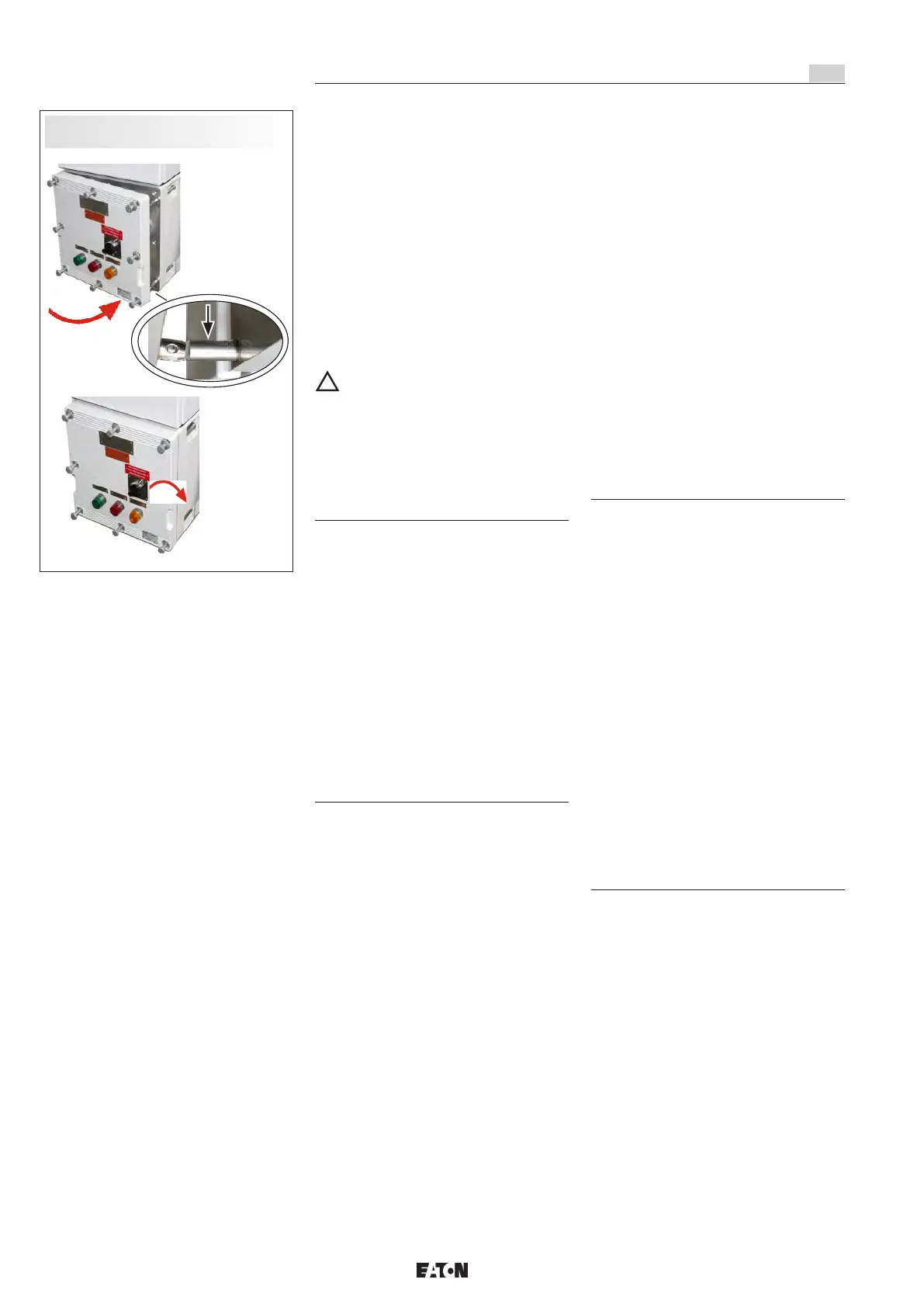

Do not clamp the restraining cord between

the enclosure cover and base.

Tighten the middle screw on the side with the

hinge first.

The following applies for enclosures with or

without optional cover hinge:

In order to ensure the required minimum

protection category, the cover screws shall be

positioned correctly and then tightened firmly.

At first, only tighten all the cover screws lightly.

Then tighten the cover screws securely in a

diagonal pattern to prevent any tension on the

cover.

X

ATEX - IEC

See Technical Data for test torques.

Over tightening of the cover screws can

damage the thread inserts in the enclosure

base an can impair the degree of protection.

6.7 Putting into operation

Before putting the apparatus into operation,

the tests specified in the individual national

regulations shall be performed.

In addition, before being put into operation, the

correct functioning of the apparatus and of the

built-in components (measuring instruments,

signal lamps, pushbuttons, etc.) shall be

checked in accordance with these operating

instructions and other applicable regulations.

a The incorrect installation and operation of

components can result in the invalidation of

the guarantee.

7 Maintenance / Servicing

a Prior to opening the enclosure, it is

necessary to ensure that the voltage supply

has been isolated or to take suitable

protective measures.

Before opening the enclosure, ensure that

no potentially explosive atmosphere is

present.

The valid national regulations for the

servicing / maintenance of electrical

apparatus for use in potentially explosive

atmospheres shall be observed

(IEC/EN 60079-17).

The necessary intervals between servicing shall

be stipulated by the operator.

Special attention should be given to ensuring

the:

– Integrity and tightness of the enclosure.

– Integrity of the flameproof joints on the

enclosure body and enclosure cover.

– Integrity of the seals, cable feeds and cable

entries.

– Cable entries shall be corrosion-free.

Clean the flameproof joints. Do not use any

sharp tools to do this. The flameproof joints

shall be smooth and not have any scratches.

Finally, apply a light coat of grease to the

flameproof joints again.

Preferred lubricant:

Renocal FN 745/94,

Renolit Unitemp 2.

Damages to any parts of the flameproof

encapsulation or flameproof joints shall be

remedied immediately using original parts or

the damaged parts shall be repaired by the

manufacturer. Otherwise the explosion

protection is no longer guaranteed.

If, in the course of servicing, it is ascertained,

that repairs are necessary, section 8 of these

operating instructions shall be observed.

8 Repair / Overhaul /

Modifications

Only original CCH parts shall be used for

carrying out repairs that concern the explosion

protection.

Repairs that affect the explosion protection

may only be carried out by Cooper Crouse-

Hinds / EATON or a qualified electrician in

compliance with the applicable national

laws (IEC/EN 60079-19).

In the event of damage to the flameproof

encapsulation or flameproof joints,

replacement of these components is

mandatory. In case of doubt, the respective

apparatus shall be returned to CCH for

repair.

Reconstruction or modifications to

apparatus are only possible within the

scope of the approvals and shall be

certified afterwards (EN 60079-19).

9 Disposal / Recycling

The respective valid national regulations for

waste disposal shall be observed when

disposing of apparatus.

The product range is subject to changes and

additions.

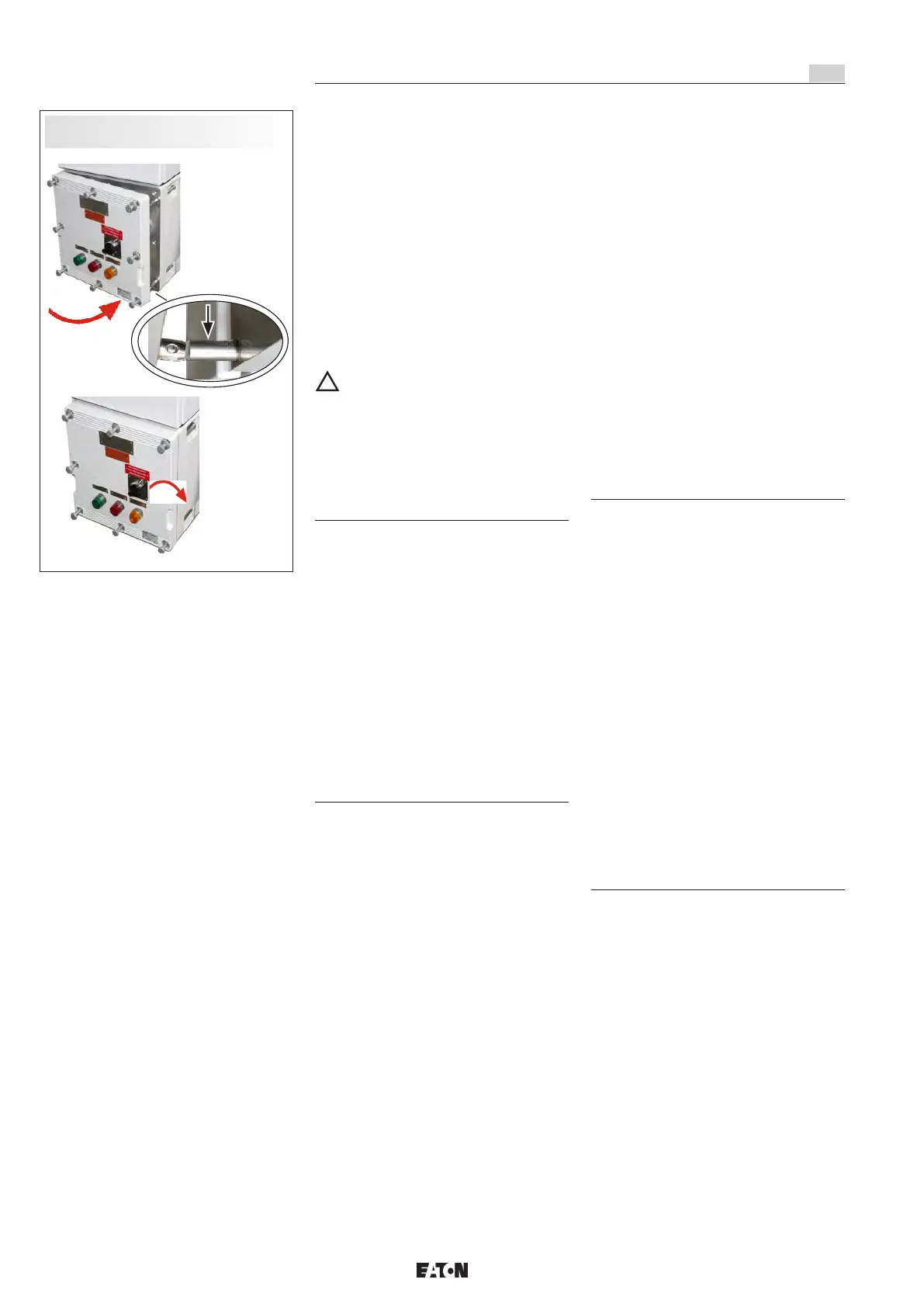

6.6 Closing apparatus / Cover lock

Any foreign matter shall be removed from

the apparatus.

Grease the joint surfaces before screwing the

enclosure cover onto the flameproof enclosure.

Preferred lubricant:

Renocal FN 745/94,

Renolit Unitemp 2.

The flat joints must not be painted or modifi-

cated!

Before closing the Ex-d enclosure with built-in

load disconnect switch, set the switch to the

„ON“ position.

When fitting the apparatus cover, care shall

be taken to ensure that the switch shaft of

the switch insert engages correctly in the

carrier hole of the switch handle.

Enclocure with optinal cover hinge:

Do not damage flameproof joints on the

enclosure cover and enclosure by making

scratches!

– Align the enclosure cover on the base.

Enclosure with optional cover hinge (Fig.5)

– Close the enclosure cover.

– Push the hinge catch back.

Take care not to crush fingers when pressing

the cover onto the enclosure base

– Press the side of the enclosure cover with

the hinge onto the base against the spring

pressure.

Fig.5 Closing

enclosure with optional hing

GB

Explosion-protected, light alloy Ex-d (e) control stations and

distributions, Series: GHG 64

Loading...

Loading...