11/2010 - Art. Nr. 4200 1029 8600A 21

Maintenance

Servicing

Work recommended as part of annual

burner maintenance:

- Burner test run, input measurement in

the boiler room

- Clean the combustion components

and replace defective parts if

necessary

- Cleaning the fan wheel and blower and

checking the pump coupling

- Check the nozzle; replace if necessary

- Checking or replacing the fuel oil filters

(pump, feed lines)

- Visual inspection of the fuel oil hoses;

replace if necessary

- Visual inspection of the burner's

electrical components; elimination of

damage if necessary

- Check burner start characteristics

- Checking oil pressure and vacuum at

the burner pump with the burner in

operation

- Flame detector and control unit

function check

- Correct the adjustment values if

necessary

- Draw up a measurement report

General checks

- Emergency stop button function check

- Visual inspection of oil lines in the

boiler room

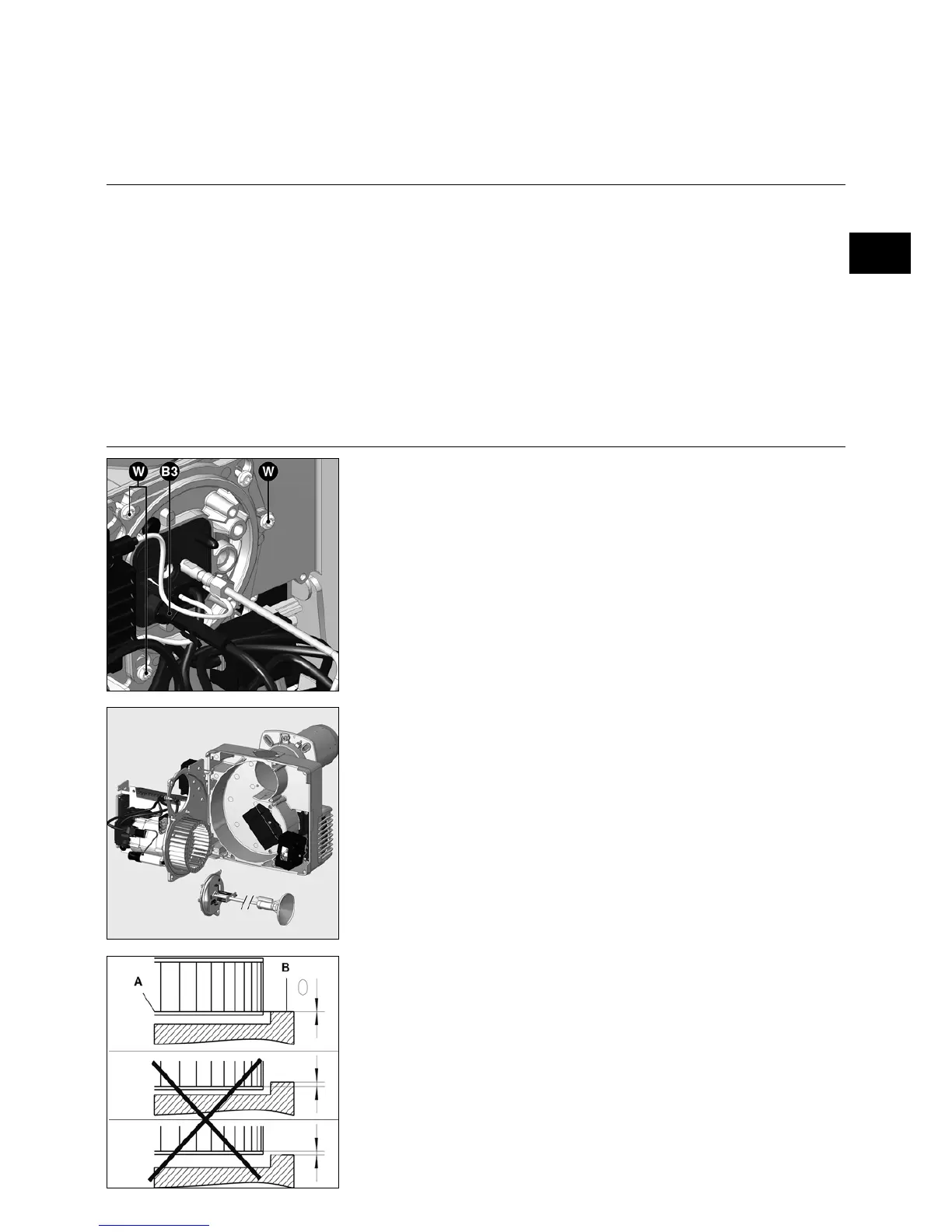

Fitting the fan wheel

When changing the motor or the fan

wheel, refer to the positioning diagram

opposite. The internal flange A of the fan

wheel must be aligned with plate B.

Insert a ruler between the vanes of the

fan wheel and bring A and B to the same

height. Tighten the cone-point screw on

the fan wheel.

Burner and boiler servicing must only

be carried out by a professional

heating engineer trained in these

operations. The system operator is

advised to take out a maintenance

contract to guarantee regular

servicing. Depending on the type of

installation, shorter maintenance

intervals may be necessary.

• Switch off the power supply before all

maintenance and cleaning work.

• Use original spare parts.

Cleaning the fan wheel

• Remove the equipment plate and

attach it in the service position (see

illustration).

• Remove and clean the fan wheel and

replace it if necessary. Reassemble in

the reverse order.

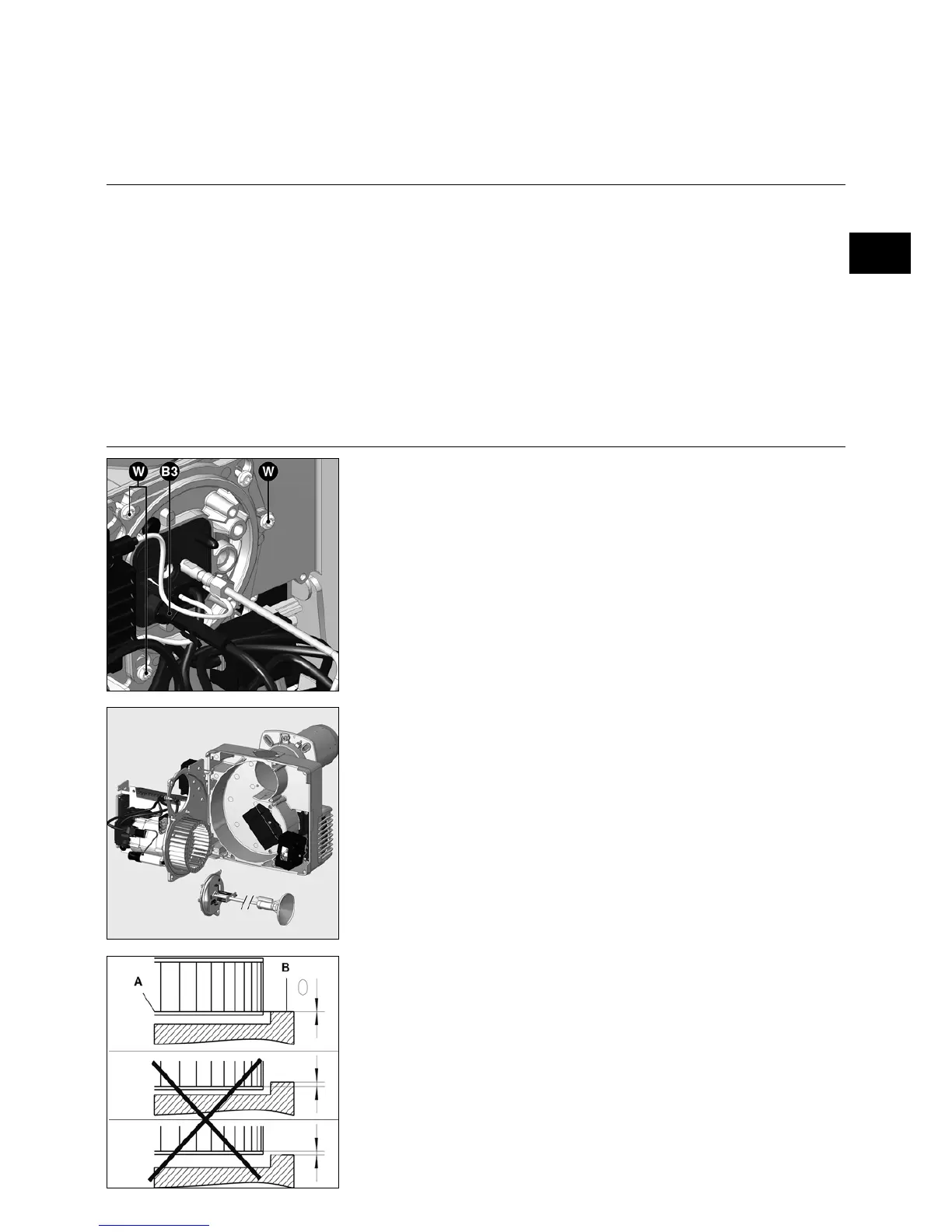

Checking checking combustion

components

• Remove the celle B3.

• Loosen the three cover screws W.

• Remove the mixing unit.

• Check nozzle size and exchange in

accordance with the parts specified in

the table page 13 if necessary.

• Check the adjustment of the ignition

electrodes block and the baffle plate

and adjust if necessary.

• Check the gap between nozzle and

baffle plate and adjust if necessary.

Loading...

Loading...