7.Output instruction

8.special display code

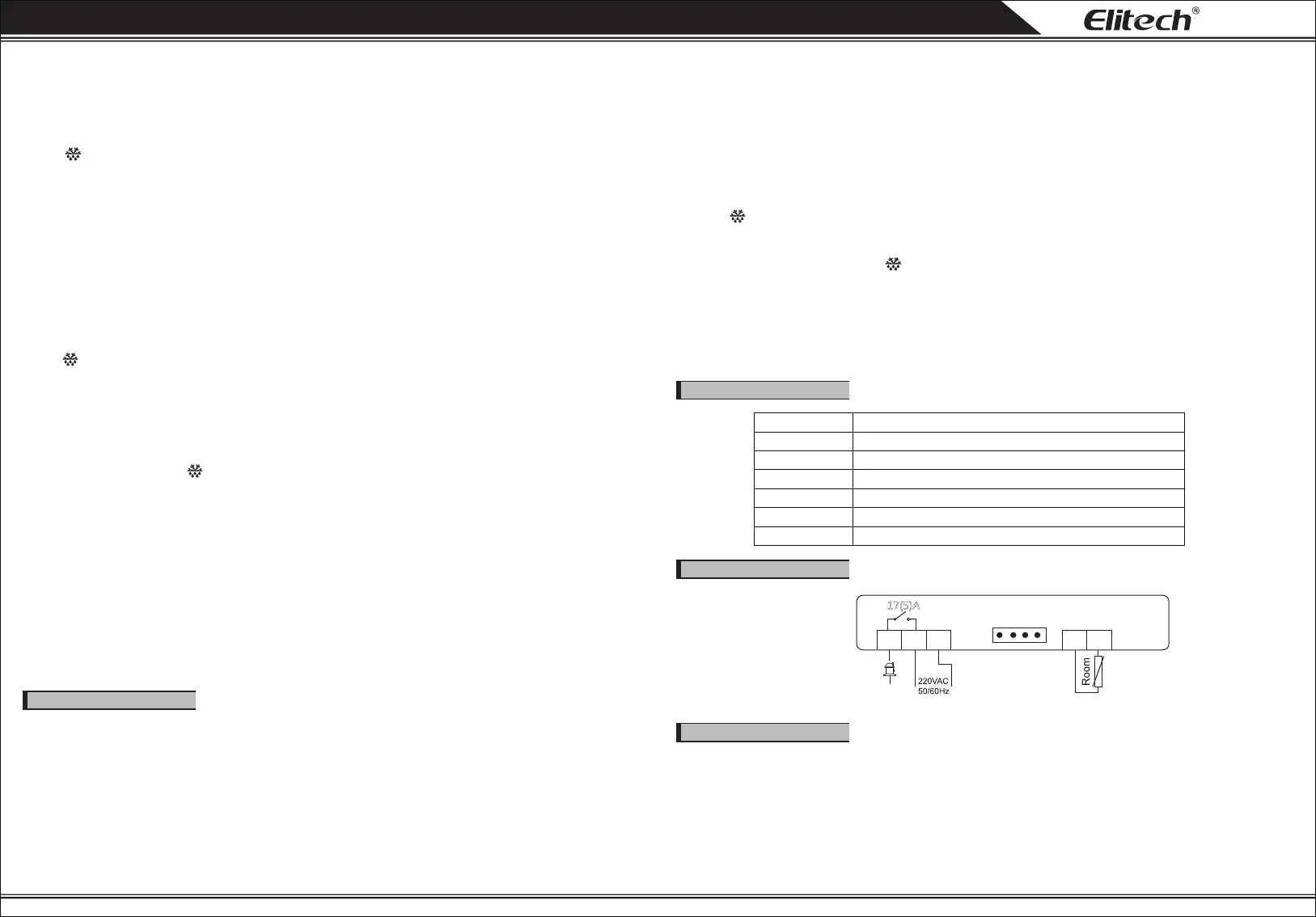

9.Wiring diagram (Refer to the actual product. )

10. Safety rules

ECS-961neo Temperature controller

EP Copy card date can’t match controller data

Parameters already recovery

Room temperature set locked

6.2 Key operaon

Set the temperature

a) Press and release “Set” to enter into the user menu, “set ” light on and display “SEt”.(Note:if LOC=n , it will display “LOC” and the

value can’t be modified)

b) Press “Set” key will display the value of “SEt” .

c) Press ▲/▼ key to adjust the value of “SEt”.

d) Press key or waing 30s to save the set point value and return to display status.

Enter password

a) Pressing “Set”key 5s, will display PA1.(Enter the correct password to enter into the administrator menu. If Password seng (PA1≠0),

will display PA1. If Password seng(PA1=0), will enter into the administrator menu directly )

b) Press “Set” key will display “00”, then press “▲”/“▼” to enter the password.

c) Aer finishing to entering the password, press “Set” key will display PA1, if the password is correct ,then will enter into the

administrator menu. Press ▲ or ▼ to choose the parameters: diF->HSE->......->CA1->ddL; or the controller will quit from the seng

status.

Universal password: 125

Parameter value set

a) Choosing the parameter code and press “Set” key.

b) Press ▲/▼ to adjust the value.

c) Press “Set” key to return the parameter display status.

d) Press or waing 30s to save the set point and return to the temperature display status.

Parameter value recovery

a) When the controller in the temperature display status , pressing both ▲+▼ 10s, will display rSt code . it means that the controller

already recovery.

b) When using the CPK-4 hot key to program the controller, it will auto double backup parameters.

c) The first is use to drive the controller and the second will use to recovery the controller.

d) Connect CPk-4 again and download the data if you want to modify the second backup parameter.

Manual Defrost funcon: pressing key 3s defrost will on or off.

Copy card

Upload (from the controller to copy card)

a) Program the controller first by hands;

b) Connect the copy card and pressing ▲ key unl display “ uP” code;

c) Aer 5S , pull up the copy card;

Download (from the copy card to the controller)

a) Aer connecng the copy card, pressing ▼ key unl display “ do” code;

b) Aer 5s, pull up the copy card;

Note: If it displays“Er”, it indicates the failure of programming. At this me, you need to check whether the copy card is reliably inserted,

if yes, repeat the above steps again.

If it displays“EP”, it indicates inconsistent data between copy card and controller, programming fails. At this me, need to change to the

right copy card and repeat the steps above; or upload the data of copy card again, and repeat the steps above.

And during this me , should provide a stable power and copy card is well connecon .

Cooling/heang:

Normal status:

HC = 0 , cooling:

When the cabinet temperature is higher than the set temperature (SEt) + hysteresis (diF), and finish the compressor start Min. interval,

the compressors will start ;

When the cabinet temperature is lower than the set temperature (SEt), the compressor will close.

HC = 1, heang :

When the cabinet temperature is lower than the set temperature (SEt) , and finish the compressor start Min. interval, the heang will start ;

When the cabinet temperature is higher than the set temperature (SEt)+ hysteresis (diF), the heang will close.

Note: if the compressor is the first me power on, compressor delay me will according( OdO) or the compressor delay me will be

according (doF).

Probe failure: Compressor will running according the set me cycle.

If Ont=0 and OFt=0, compressor will be always close.

If Ont=0 and OFt≠0, compressor will be always close.

If OFt=0 and Ont≠0, compressor will be always running.

Defrost:

1)dEt=0, defrost is forbidden.

2)dEt≠0, defrost will be acvaon according any below condions:

a) If dPO=y, defrost will start aer running out the me of defrost delay(dOH).

b) Aer running out the me of “dit”, will start the defrost funcon.

Note: defrost cycle (dit) and (dOH) will according dCt( 0,1,2).

c) Pressing 3S, start to defrost.

3) In the state of defrost (Any of the following condion could close defrost):

① Will close the defrost when run out the me of dEt.

② Will close the defrost funcon if pressing key 3S.

4) Compressor start to work aer the defrost.

Note: the status of display during the defrost :

ddL=0: display the real temperature.

ddL=1: display the temperature when start to defrost, defrost closing and room temperature ≤the seng temperature, then will display

the real temperature.

ddL=2: display “dEF”, defrost closing and room temperature ≤the seng temperature, then will display the real temperature.

★Danger:

1) Strictly disnguish the power wire, relay output, sensor down-lead and data line, and the relay could not be overloaded.

2) Prohibit connecng the wire terminals without electricity cut-off.

★Warning:

Prohibit using this unit under the environment of over damp, high temp, strong electromagnesm interference or strong corrosion.

★Noce:

1) The power supply should conform to the voltage value indicated in the instrucon, and make sure a steady power supply.

2) To avoid the possible interference, the sensor down-lead/data line and power wire should be kept in a proper distance.

17(5)A

NL

Power

Hot Key

N

1 2 3 4 5

Loading...

Loading...