Page 1 of 5

109-6182 Rev. A

Loose Parts

Note: Use the chart below to verify that all parts have been shipped.

109-6181 Dealer Pack

Part # Description Qty Use

323-6

98-5975

3290-357

Cap Screw, Hex 3/8-16 x 1

Washer, Belleville

Nut, Hex Flange 3/8-16

8

8

8

Installing the Rollover Protection System (Roll Bar)

103-1309 Warranty Registration Form 1 Fill out and return to Exmark

103-2106 Keys 1 Unit ignition

32128-20 Nut, 5/16-18 Whizlock 4 For fastening seat tracks to unit seat frame

1-303335 Tie, Plastic 2 For fastening seat wiring to seat prop rod

109-6178 Literature Pack

Part # Description Qty Use

-----------

-----------

Manual, Operator’s

Manual, Parts

1

1

Read before operating machine.

109-3498 DVD, Exmark Safety Video 1 View before operating machine.

109-6435 Sheet, Emissions Warranty 1

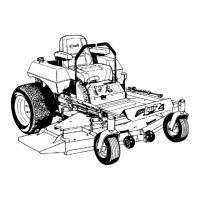

Installing the Rollover Protection

System (Roll Bar)

1. Remove sides and top of crate from the base.

2. Remove roll bar components from the crate.

3. Remove roll bar tubes from sides of crate.

4. Remove the two brackets used to mount the

bottom of the upper roll bar tube to the crate.

5. Remove the 1/2-13 x 3 1/4 capscrews and 1/2-13

hex flange lock nuts from the two brackets at

each end of the upper roll bar tube and retain for

later use (Fig. 1).

6. Remove the (4) 1/4” lag screws holding the wheel

hub brackets to the crate bottom and discard.

7. Raise the rear of the unit approximately 10-12”

and support it with jack stands or equivalent

support.

CAUTION

POTENTIAL HAZARD

♦ Raising the rear of the unit for assembly relying

solely on mechanical or hydraulic jacks could

be dangerous.

WHAT CAN HAPPEN

♦ The mechanical or hydraulic jacks may not be

enough support or may malfunction allowing

the unit to fall, which could cause injury.

HOW TO AVOID THE HAZARD

♦ DO NOT rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

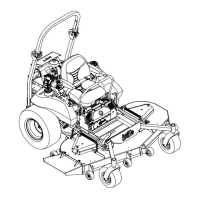

8. Locate the left and right lower roll bar tubes.

9. Align lower roll bar tubes along rear engine frame

(Fig. 2).

10. LOOSELY install lower roll bar hardware (four

3/8-16 x 1 capscrews, four spring disk washers

and four 3/8-16 whizlock nuts) to the tubes on

each side. (Fig. 2).

LAZER Z

(AIR COOLED)

SETUP INSTRUCTIONS

FIGURE 1

For Serial Nos. 670,000 and Highe

Loading...

Loading...