Paragraph 47

FORD

ENGINE BALANCER

Model 2110

47.

To remove balancer assembly,

first drain engine oil. If equipped with

front wheel drive, remove front axle and

drive shaft. Remove engine oil pan.

Remove balancer bottom cover (9-Fig.

96).

Remove balancer mounting cap

screws, then lower balancer assembly

from engine. Note that hollow dowels (6)

are used to position balancer on engine

block and may restrict removal of

balancer. Retain shims (7), if used, for

use in installation.

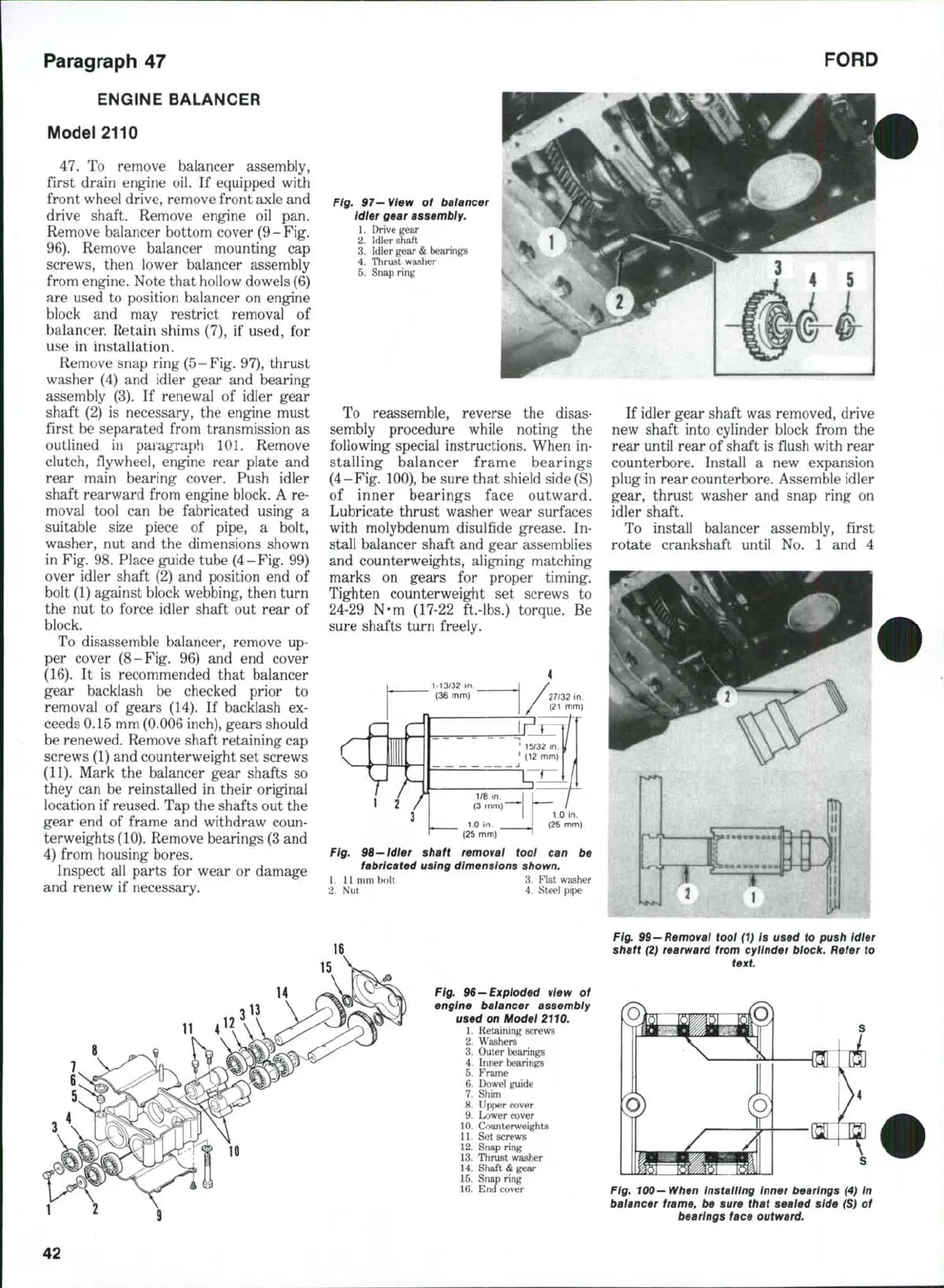

Remove snap ring

(5

- Fig, 97), thrust

washer (4) and idler gear and bearing

assembly (3), If renewal of idler gear

shaft (2) is necessary, the engine must

first be separated from transmission as

outlined in paragraph 101. Remove

clutch, flywheel, engine rear plate and

rear main bearing cover. Push idler

shaft rearward from engine block. A re-

moval tool can be fabricated using a

suitable size piece of pipe, a bolt,

washer, nut and the dimensions shown

in Fig. 98. Place guide tube (4-Fig, 99)

over idler shaft (2) and position end of

bolt (1) against block webbing, then turn

the nut to force idler shaft out rear of

block.

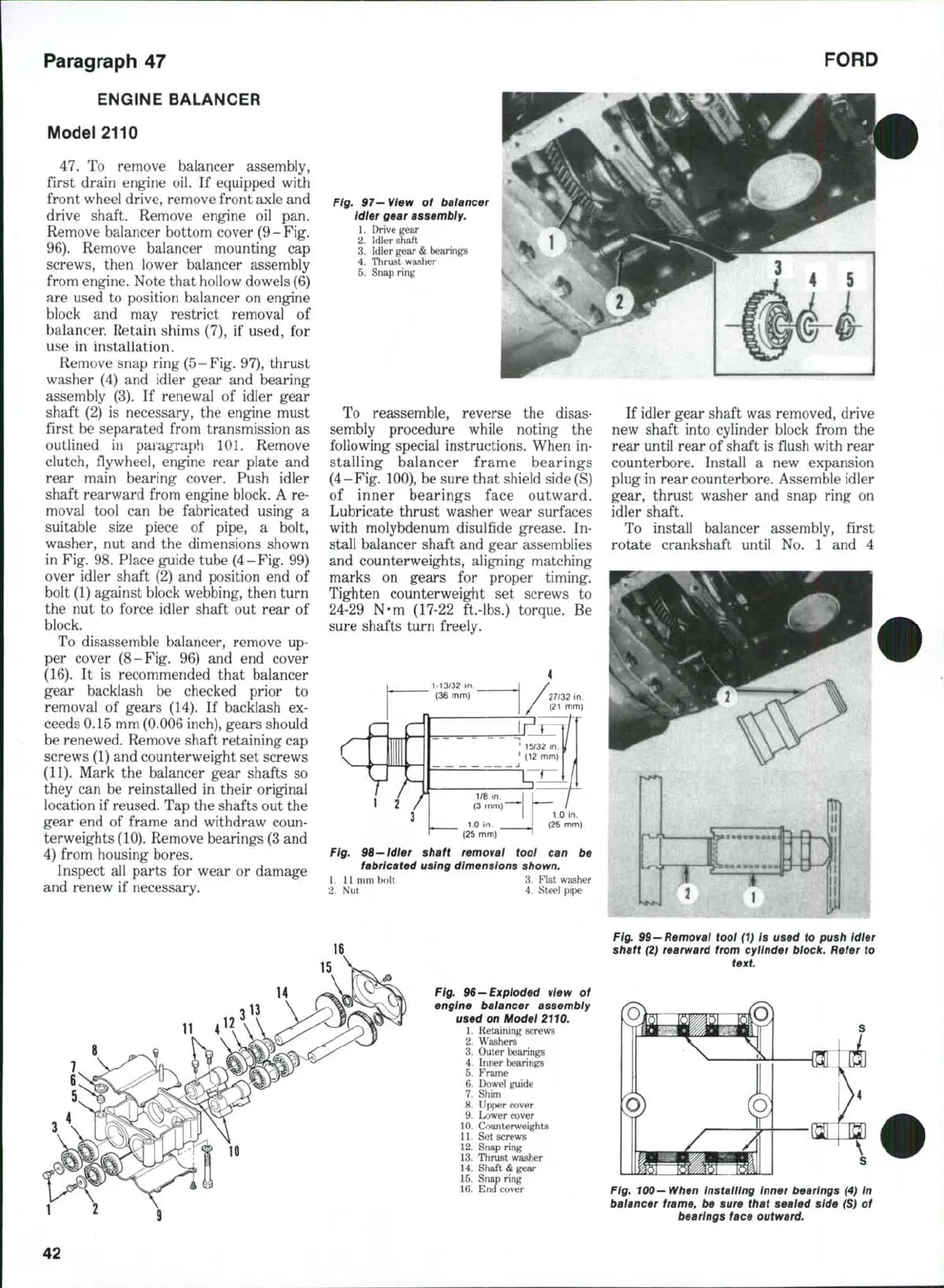

To disassemble balancer, remove up-

per cover (8-Fig. 96) and end cover

(16).

It is recommended that balancer

gear backlash be checked prior to

removal of gears (14). If backlash ex-

ceeds 0,15 mm (0.006 inch), gears should

be renewed. Remove shaft retaining cap

screws (1) and counterweight set screws

(11).

Mark the balancer gear shafts so

they can be reinstalled in their original

location if reused. Tap the shafts out the

gear end of frame and withdraw coun-

terweights

(10).

Remove bearings

(3

and

4) from housing bores.

Inspect all parts for wear or damage

and renew if necessary.

Fig. 97-View of balancer

Idler gear assembly.

1.

Drive gear

2.

Idler shaft

3.

Idler gear & bearings

4.

Thrust washer

5.

Snap ring

To reassemble, reverse the disas-

sembly procedure while noting the

following special instructions. When in-

stalling balancer frame bearings

(4-Fig. 100), be sure that shield side (S)

of inner bearings face outward.

Lubricate thrust washer wear surfaces

with molybdenum disulfide grease. In-

stall balancer shaft and gear assemblies

and counterweights, aligning matching

marks on gears for proper timing.

Tighten counterweight set screws to

24-29 N-m (17-22 ft.-lbs.) torque. Be

sure shafts turn freely.

1.0

in.

(25

mm)

Fig, 96—Idler shaft removal tool can be

fabricated using dimensions shown,

1.

11 mm bolt 3. Flat washer

2.

Nut 4. Steel pipe

If idler gear shaft was removed, drive

new shaft into cylinder block from the

rear until rear of shaft is flush with rear

counterbore. Install a new expansion

plug in rear counterbore. Assemble idler

gear, thrust washer and snap ring on

idler shaft.

To install balancer assembly, first

rotate crankshaft until No. 1 and 4

Fig.

99 —

Removal tool (1) Is used to push Idler

shaft

(2)

rearward from cylinder block. Refer to

text

Fig, 96-Exploded view of

engine baiancer assembly

used on Model 2110.

1.

Retaining screws

2.

Washers

3.

Outer bearings

4.

Inner bearings

5.

Frame

6. Dowel guide

7.

Shim

8. Upper cover

9. Lower cover

10.

Counterweights

11.

Set screws

12.

Snap ring

13.

Thrust washer

14.

Shaft

&

gear

15.

Snap ring

16.

End cover

S

Fig, 100-When installing Inner bearings (4) In

balancer frame, be sure that sealed side (S) of

bearings face outward.

Loading...

Loading...