Installation Instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and 1 in. rear. Consideration

must be given to provide adequate clearance for proper operation and service.

ITI PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better accesswheninstalling dryer exhaust

DISCONNECTING_ GAS _i v

TURNGAS _ DISCONNECTANDDISCARDOLD

SHUT-OFF I_>_ FLEXIBLEGASCONNECTORAND _CT' _,

OFF

APPROVEDFLEXIBLEGASLINE

CONNECTORANDULAPPROVED

TRANSITIONDUCT.

WARNING - NEVER REUSE OLD

FLEXIBLE CONNECTORS.

The use of old flexible connectors can cause leaks and

personal injury. Always use new flexible connectors when

installing gas appliances.

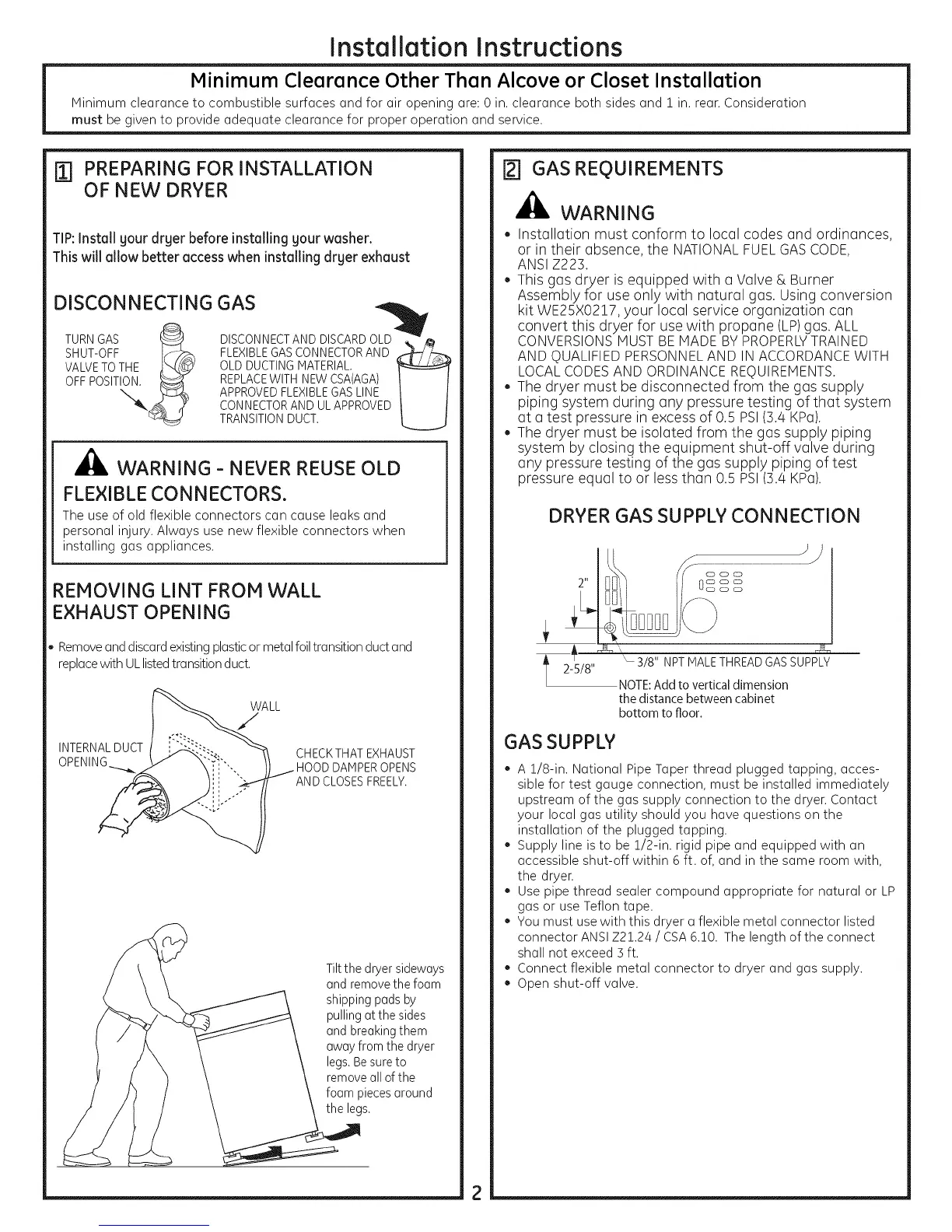

REMOVING LINT FROM WALL

EXHAUST OPENING

• Removeand discardexistingplasticor metalfoil transitionduct and

replacewith ULlistedtransition duct.

WALL

INTERNALDUCT

CHECKTHAT EXHAUST

DAMPEROPENS

AND CLOSESFREELY,

Tiltthe dryer sideways

and removethe foam

shippingpads by

pullingatthe sides

and breakingthem

awayfrom the dryer

legs.Besureto

removeall ofthe

foam piecesaround

the legs.

_] GAS REQUIREMENTS

_i, WARNING

• Installation must conform to local codes and ordinances,

or in their absence, the NATIONAL FUEL GAS CODE,

ANSI Z223.

This gas dryer is equipped with a Valve & Burner

Assembly for use only with natural gas. Using conversion

kit WE25X0217, your local service organization can

convert this dryer for use with propane (LP) gas. ALL

CONVERSIONS HUST BE HADE BY PROPERLYTRAINED

AND QUALIFIED PERSONNEL AND IN ACCORDANCE WITH

LOCAL CODES AND ORDINANCE REQUIREHENTS.

The dryer must be disconnected from the gas supply

piping system during any pressure testing of that system

at a test pressure in excess of 0.5 PSI (3.4 KPa).

The dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping of test

pressure equal to or less than 0.5 PSI (].4 KPa).

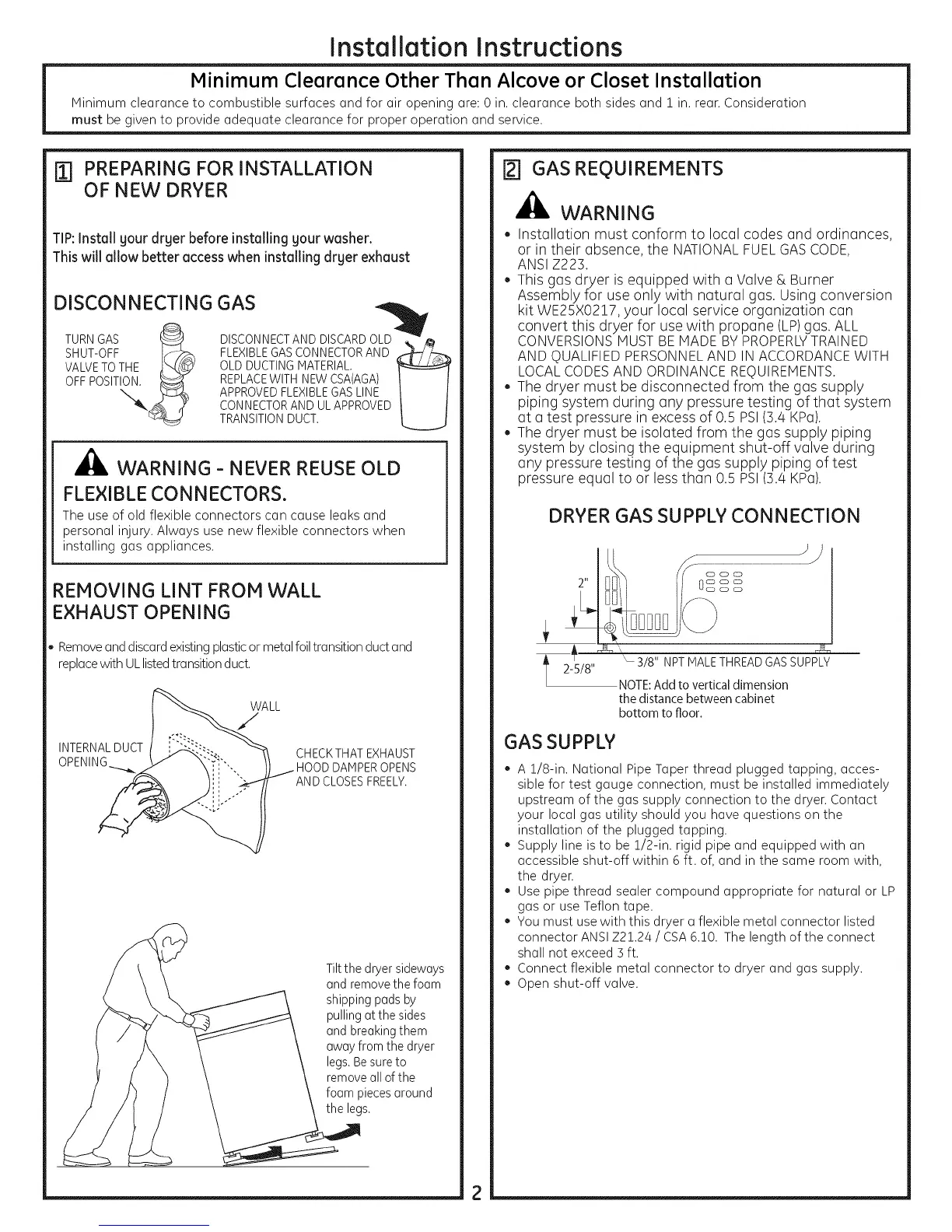

DRYER GAS SUPPLY CONNECTION

t

2-5/8"

'- 3/8" NPT MALETHREADGAS SUPPLY

NOTE: Add to vertical dimension

the distance between cabinet

bottom to floor.

GAS SUPPLY

A 1/8-in. National Pipe Taper thread plugged tapping, acces-

sible for test gauge connection, must be installed immediately

upstream of the gas supply connection to the dryen Contact

your local gas utility should you have questions on the

installation of the plugged tapping.

Supply line isto be 1/2-in. rigid pipe and equipped with an

accessible shut-off within 6 ft. of, and in the same room with,

the dryen

Use pipe thread sealer compound appropriate for natural or LP

gas or use Teflon tape.

You must use with this dryer a flexible metal connector listed

connector ANSI Z21.24 / CSA6.10. The length of the connect

shall not exceed ] ft.

Connect flexible metal connector to dryer and gas supply.

Open shut-off valve.

Loading...

Loading...