FAILURE CODESSERVICE MODE

Service Mode can be entered by the following steps:

1. Press and Hold the Front Right Burner ON/OFF key for 7 seconds

until tone is heard and “1” appears on the timer.

2. Press and Hold Rear Right Burner ON/OFF key for 7 seconds

until tone is heard and Software version appears on the timer.

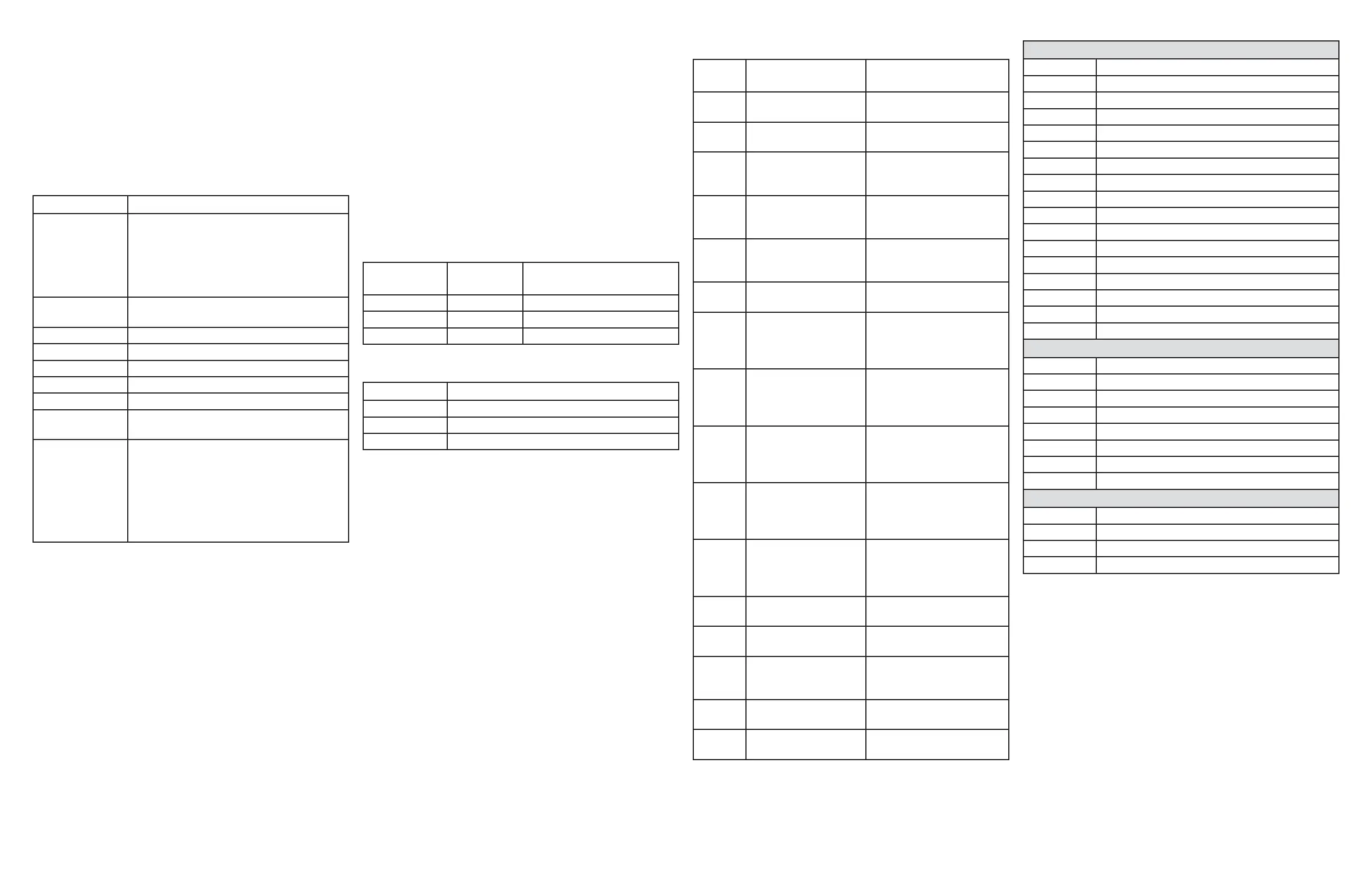

SEt – SETTING UP SERVICE REPLACEMENT CONTROLS

Service Replacement UIs must be set up with the appropriate

model number to function correctly.

1. After replacing the control, power up the unit.

2. Upon power up the UI will display the letter SEt after a few

VHFRQGV2QWKH*(8,XQLWVDOOWKH/('VPD\WXUQRQ¿UVWIRUXS

to 10 seconds before SEt appears on screen.)

3. Using the Timer up and down keys select the correct model

QXPEHUEDVHGRȺWKHWDEOHEHORZ

4. Press and Hold the Timer Select (or Timer Start on models where

this key is available) for 7 seconds to store this model number in

the control.

5. The control should restart and operate normally.

DIAGNOSTICS MODE SUMMARY

MODEL SELECTIONS FOR 36” INDUCTION

The Table below describes what key provides what diagnostic

features each key will do.

Key Response

Left Rear + Displays failure codes on the Timer. Pressing

this key multiple times will cycle through

each failure code until dashes appear

showing the end of the codes. If no active

failures exist only dashes will be shown with

each press.

$OO2Ⱥ Pressing and holding for 5 seconds will clear

the Failure Code that is currently displayed.

Left Front + Turns on all the LEDs for 5 seconds.

Left Front - Exit Service Mode.

Right Front - Display main board software version

Right Front + Display Induction board #1 software version

Right Rear - Display Induction board #2 software version.

Right Rear + Display Induction board #3 software version

(On 30” unit, this key is not valid).

Timer Select

(or Timer ON/OFF)

ONLY use this when a mistake has been

made in setting the model number for a

service replacement board.

To clear the service model number, press and

hold for 7 seconds. Control will show SEt in

timer block, ready to reprogram the service

control’s model number.

Service

Model Index Model Description

AA2 CHP9536xxxx 36” Induction Café Blue

AF2 ZHU36Rxxxx 36” Induction Monogram White

C2 PHP9036xxxx µ,QGXFWLRQ3UR¿OH

User Interface

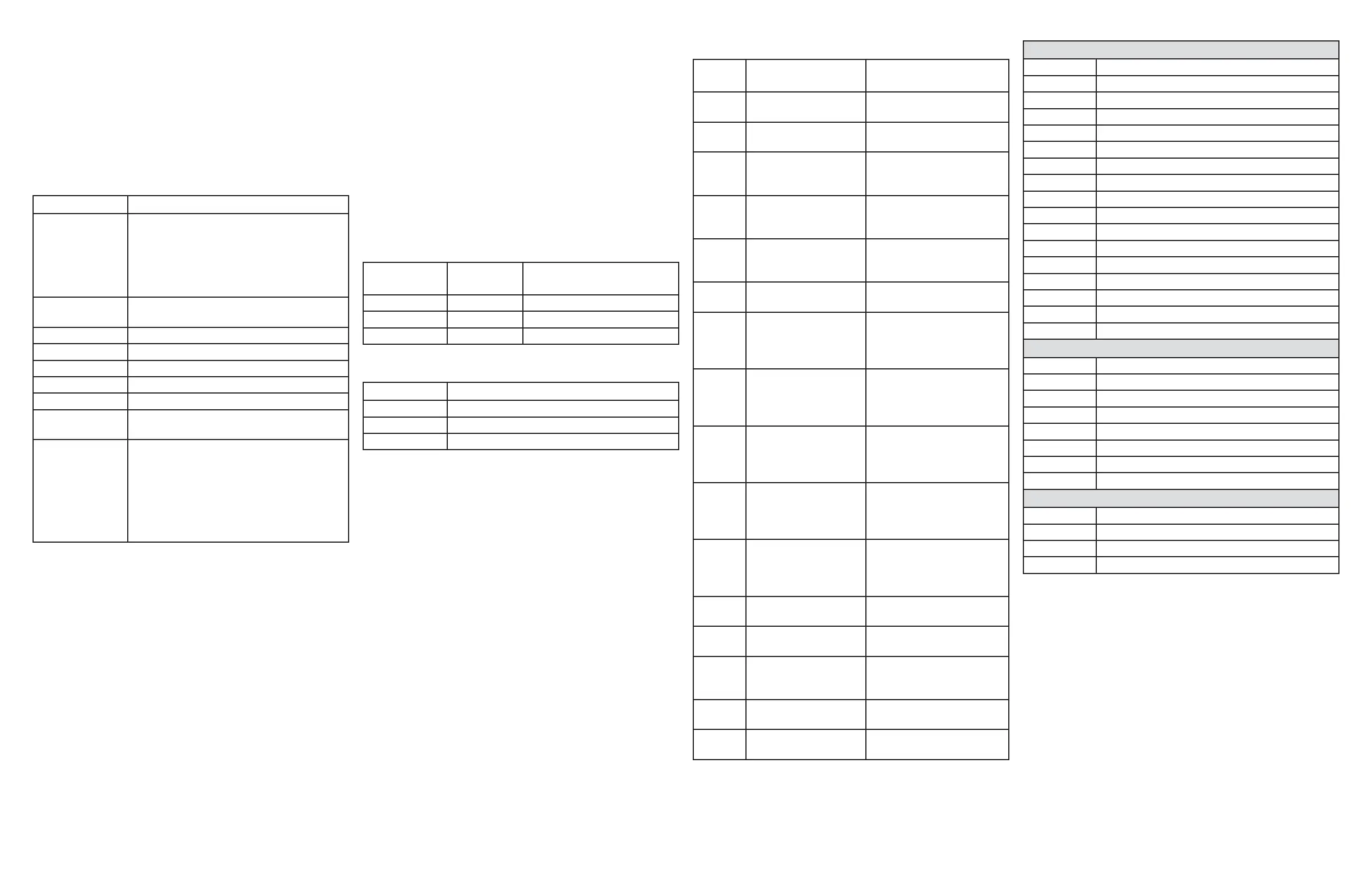

J1 Pin1 7.5V DC Power

J1 Pin2 GE Communication Bus

J1 Pin3 NC

J1 Pin4 Heating Enable. +5VDC Active

J1 Pin5 NC

J1 Pin6 NC

J1 Pin7 NC

J1 Pin8 Logic Ground

J6 Pin1 Service 7.5V DC Power

J6 Pin2 Service Communication Bus

J6 Pin3 Service Logic Ground

J4 Pin1 Fan 2 Speed Detection

J4 Pin2 Fan 1 Speed Detection

J4 Pin3 Fan 2 Low Speed. +5VDC Active

J4 Pin4 Fan 2 High Speed. +5VDC Active

J4 Pin5 Fan 1 Low Speed. +5VDC Active

J4 Pin6 Fan 1 High Speed. +5VDC Active

Induction Tray – Filter Board

J8 Pin1 Logic Ground

J8 Pin2 Heating Enable. +5VDC Active

J8 Pin3 Fan Speed Detection

J8 Pin4 12V DC Power

J8 Pin5 7.5V DC Power

J8 Pin6 Fan High Speed. +5VDC Active

J8 Pin7 Fan Low Speed. +5VDC Active

J8 Pin8 NC

Induction Tray – Generator Board

J501 Pin1 7.5V DC Power

J501 Pin2 Communication Bus

J501 Pin3 Logic Ground

J502 Pin1~4 Model Selector Plug

Fault

Code Issue Description Possible Fixes

SEt Model number not

programmed into UI

Program model number via

service tools.

F10~F11 Problem with LED’s on

user interface

Check Power. Replace UI

Board.

F61 Cannot communicate

with induction module

that powers left coils

Check wires connecting UI

to induction Tray. Replace

UI. Replace induction Tray.

F62 Cannot communicate

with Induction Module

that powers right coils

Check wires connecting UI

to induction Tray. Replace

UI. Replace induction Tray.

F63 Cannot communicate

with induction module

that powers right coils

Check wires connecting UI

to induction Tray. Replace

UI. Replace induction Tray.

F70~F76 User Interface key error Clean UI. Cycle power.

Replace UI Board.

FA0 Fan Harness(is) not

connected

Check wires connecting UI

to Induction Tray. Check

Fan, UI and induction Tray.

Replace fan.

FA1 Fan1 is not running at

the correct Low speed

Check wires connecting UI

to Induction Tray. Check

Fan, UI and induction Tray.

Replace fan.

FA2 Fan1 is not running at

the correct High speed

Check wires connecting UI

to Induction Tray. Check

Fan, UI and induction Tray.

Replace fan.

FA3 Fan2 is not running at

the correct Low speed

Check wires connecting UI

to Induction Tray. Check

Fan, UI and induction Tray.

Replace fan.

FA4 Fan2 is not running at

the correct High speed

Check wires connecting UI

to Induction Tray. Check

Fan, UI and induction Tray.

Replace fan.

FA5, FA9,

FAA

Bad coil thermistor

reading

Check coil thermistor and

induction Tray. Replace coil.

FA6 Low or high line voltage Check line voltage. Replace

Induction Tray.

FA7 Missing line frequency Check line voltage/

frequency. Replace

Induction Tray.

FA8, FAB Bad induction driver

(IGBT)

Replace Induction Tray.

FAC Induction

microprocessor error

Replace Induction Tray.

THERMISTOR RESISTANCE READINGS

Degrees F Thermistor Resistance (approximate)

72° F Nű

150° F Nű

518° F ű

RJ-45 is a service jack provided for GE technicians to use on the

front left bottom corner of the unit.

MODEL NUMBER

PHP9036

IMPORTANT

SERVICE INFORMATION

DO NOT DISCARD

Pub No. 31-17142 10-14 GE

Loading...

Loading...