3A3951A

EN

Repair Kit Instructions

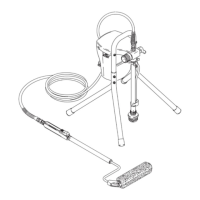

Repair Kits for

Magnum ProX & GX Sprayers

Use these instructions when repairing the ProX or GX sprayers.

Contents

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in the repair kit instructions and in the Owners/Operation manual for the

sprayer.

Section Description Kit #

1 Drive

Front Cover Replacement page 3 17J866

Motor Replacement page 3 17F756, 17F757, 17F758,

17K684, 17L083

Fan Replacement page 4 16X980, 287770

Gear & Yoke Replacement page 5 17J863, 17J864, 17J869

2 Control Control Board Replacement page 7 17J867, 17J885

3 Pump

Pressure Control Replacement page 9 17J881, 17J927

Prime/Spray Valve and Knob Replacement page 10 17J925, 235014

Pump Outlet Valve Replacement page 11 17J880

Pump Inlet Valve Replacement page 12 17J876, 17J877, 17J924

PushPrime Button Replacement page 12 17J878

4 Accessories Magnum ProX Lacquer Conversion page 13 17J873, 17L305

Refer to the illustrations in this document and your

Owners/Operation manual for additional parts

information, wiring diagrams, and any additional

assembly torques that you may need.

Pressure Relief Procedure

Before servicing the sprayer, pump pressure must be

relieved.

1. Turn ON/OFF switch to the OFF position.

2. Engage the trigger lock. Always engage the trigger

lock when sprayer is stopped to prevent the gun

from being triggered accidentally.

3. Turn pressure control to lowest setting.

4. Put drain tube into a pail and place Prime/Spray

valve in PRIME position (drain) to relieve pressure.

5. Hold the gun firmly to a pail. Point gun into pail. Dis-

engage the trigger lock and trigger the gun to

relieve pressure.

6. Engage the trigger lock.

7. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. VERY SLOWLY loosen the spray tip guard

retaining nut or the hose end coupling to relieve

pressure gradually.

b. Loosen the nut or coupling completely.

c. Clear airless hose or spray tip obstruction.

SKIN INJECTION HAZARD: This sprayer builds up

an internal pressure of 3000 psi (20.7 MPa, 207

bar) during use. This equipment stays pressurized

until pressure is manually relieved. Follow this

Pressure Relief Procedure whenever you stop

spraying and before cleaning, checking, servicing,

or transporting equipment to prevent serious injury.

Loading...

Loading...