63

Duct Type Split Air Conditioner

Service Manual

7. Recover the electric heating

tape of compressor and discharge

temperature sensor,etc.

Enwind the bottom of compressor with electric

heating tape and x it.

8. Check if the compressor rotates in

reverse and if lubricant have leaked

Check if the wiring is correct with reference to

circuit diagram and check if there is any leakage

after welding.

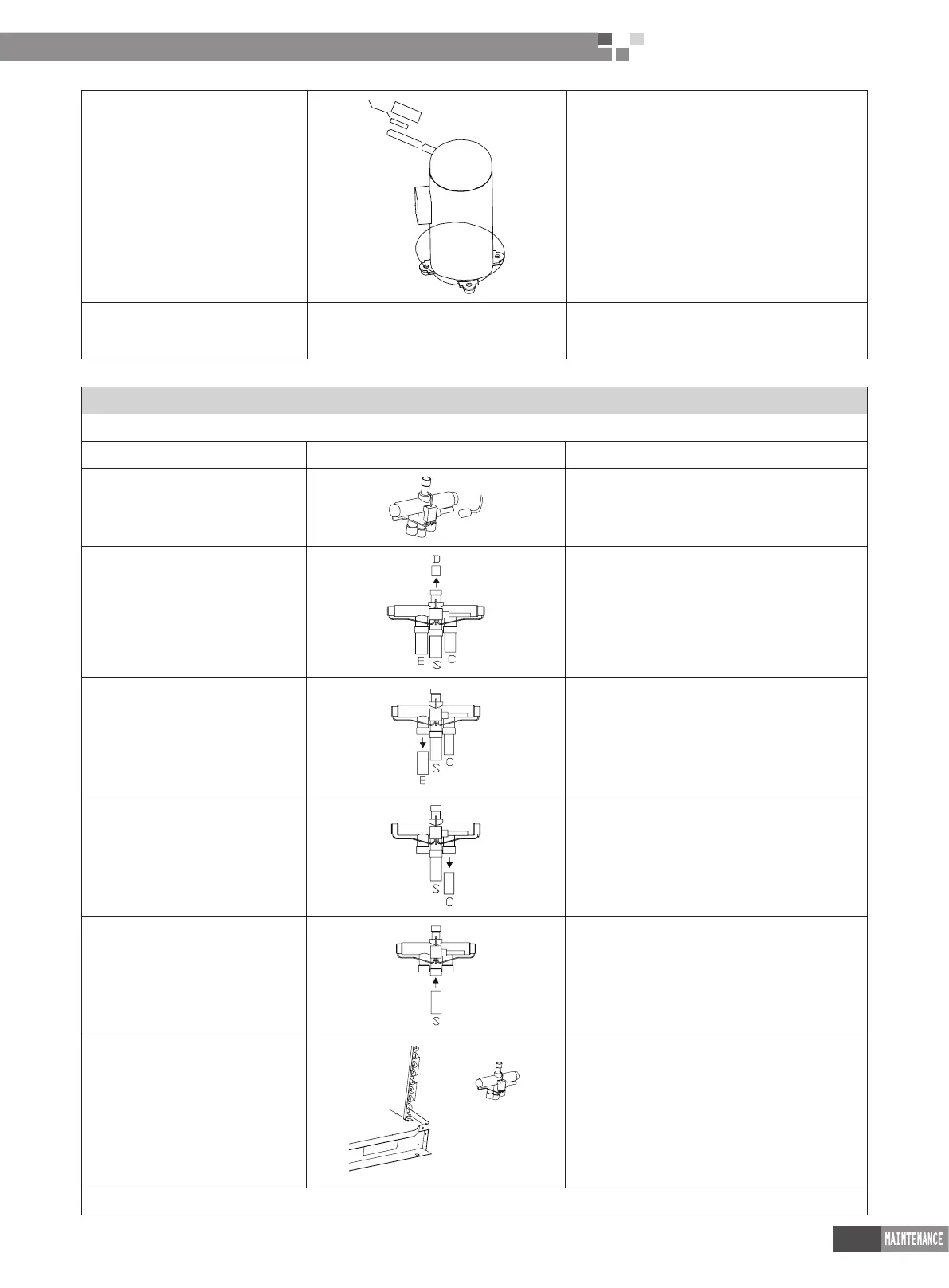

Disassembly and Assembly of 4-way valve

Remark: Make sure that there isn’t any refrigerant in pipe system and the power supply is cut off before removal of 4-way valve.

Step Illustration Handling Instruction

Remove electric coils of 4-way valve

Place electric coils far away from the 4-way valve

to prevent the connecting line of 4-way valve from

burning when succeeding welding.

Disconnect the pipe (site D in

illustration) of 4-way valve and

ischarge pipe

Don’t leave welding slag inside pipes.

Disconnect the pipe (site E in

illustration) of 4-way valve and

connecting pipe

Don’t leave welding slag inside pipes.

Disconnect the pipe (site C

in illustration) of 4-valve and

connecting pipe

Don’t leave welding slag inside pipes.

Disconnect the pipe (site S in

illustration) of 4-way valve and

connecting pipe

Don’t leave welding slag inside pipes.

Remove the 4-way valve Remove 4-way valve after it is cooled.

Install new 4-way valve in reversed order and wrap it with wet cloth before welding.

Loading...

Loading...