GMV DC Inverter VRF

36

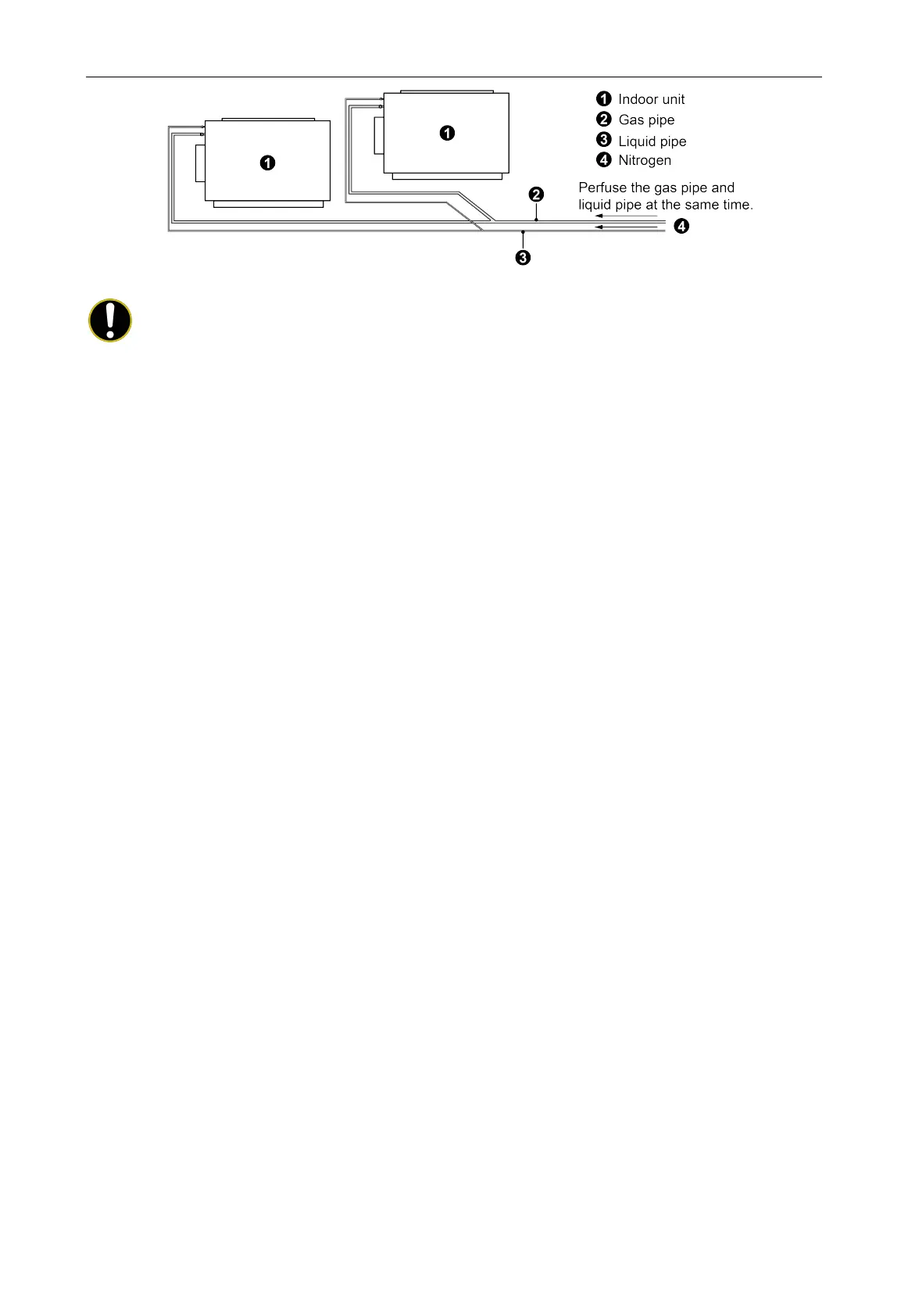

Fig. 3.6.1

NOTE!

All welding points can't be heat-insulated and wrapped until the air tightness test is completed.

(2) Operation procedures for the air tightness test

When leaving the factory, gas pipe, liquid pipe and cut-off valve of outdoor unit have been closed.

Please confirm it during installation.

Before the test, a small amount of lubricant oil required by the corresponding system should be

smeared at the nut and the end of the pipe. Two wrenches should be used when fixing the nut.

It is not allowed to connect the pipeline of outdoor unit for test during the air tightness test.

The test pressure for R410A system is 4.15MPa. The air tightness test must use nitrogen as the

medium and the nitrogen should be dried. Slowly increase the pressure in three steps:

Step 1: slowly increase the pressure to 0.5MPa, stay for 5 minutes and conduct the leakage

inspection. You may find big leakage;

Step 2: slowly increase the pressure to 1.5MPa, stay for 5 minutes, conduct the air tightness

inspection, and you may find small leakage;

Step 3: Slowly increase the pressure for R410A system to 4.15MPa, stay for 5 minutes and

conduct the strength test. You may find small penetration or blisters. After increasing the pressure to

the test pressure, hold the pressure for 24 hours, and observe whether the pressure drops. If the

pressure does not drop, it is qualified.

3.6.2 Vacuum Drying

(1) Selection requirements for vacuum pumps.

1) Can't vacuumize different refrigerant systems with the same vacuum pump.

2) The ultimate vacuum of the vacuum pump should be -0.1Mpa.

3) The air displacement of the vacuum pump should be above 4L/s.

4) The accuracy of the vacuum pump should be above 0.02mmHg.

5) The system vacuum pump must have a check valve.

(2) Operation procedures of vacuum drying.

1) Before vacuuming, confirm that the stop valves of gas pipe and liquid pipe are at closed

status.

2) Connect the regulating valve and vacuum pump to the inspection joint of the gas pipe

valve and liquid pipe valve valves with a filling tube.

Loading...

Loading...