English (GB)

11

10. Wrap the rotor in a protective material, such as cardboard, to

protect it from scratches.

11. Place the rotor on the vice. Do not tighten the vice on the

rotor!

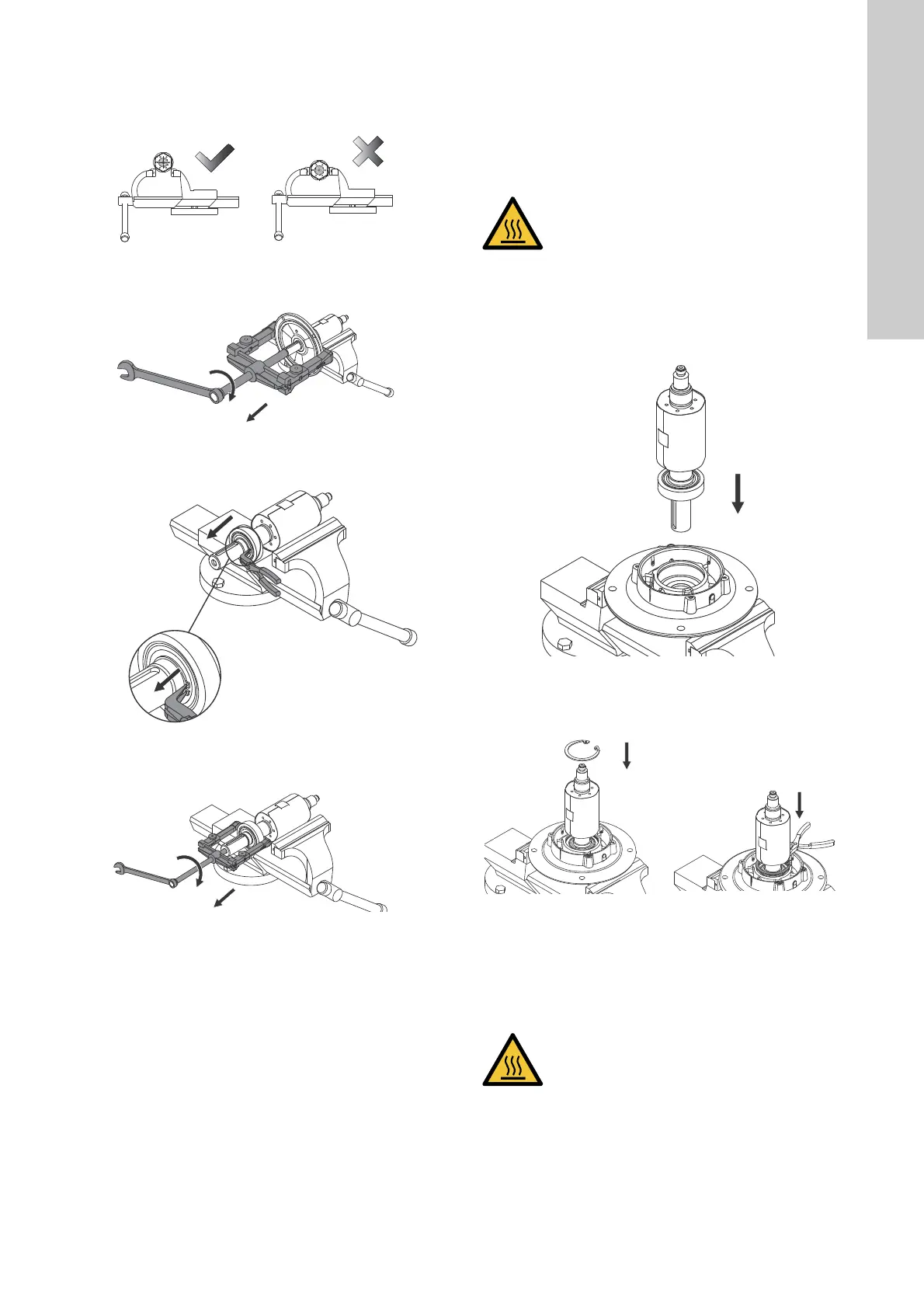

Fig. 15 Correct position of the rotor on the vice

12. Pull the flange from the rotor with a puller.

Fig. 16 Pulling the flange from the rotor

13. Remove the locking ring (188) from the shaft.

Fig. 17 Removing the locking ring

14. Remove the bearing (153) with a puller.

Fig. 18 Removing the bearing with a puller

Assembly

1. Place the rotor on a vice. Do not tighten the vice on the rotor!

2. Clean the bearing journal in the drive end with a clean cloth.

3. Heat the new bearing (153) to a temperature between 90 and

110 °C. Follow the instructions for the bearing and bearing

heater.

4. Fit the heated bearing on the drive end of the shaft.

5. Fit the locking ring (188) on the shaft.

6. Place the flange in the vice.

7. Clean the bearing seat with a clean cloth and lubricate the

bearing seat with anti-fretting paste.

8. Fit the rotor in the flange.

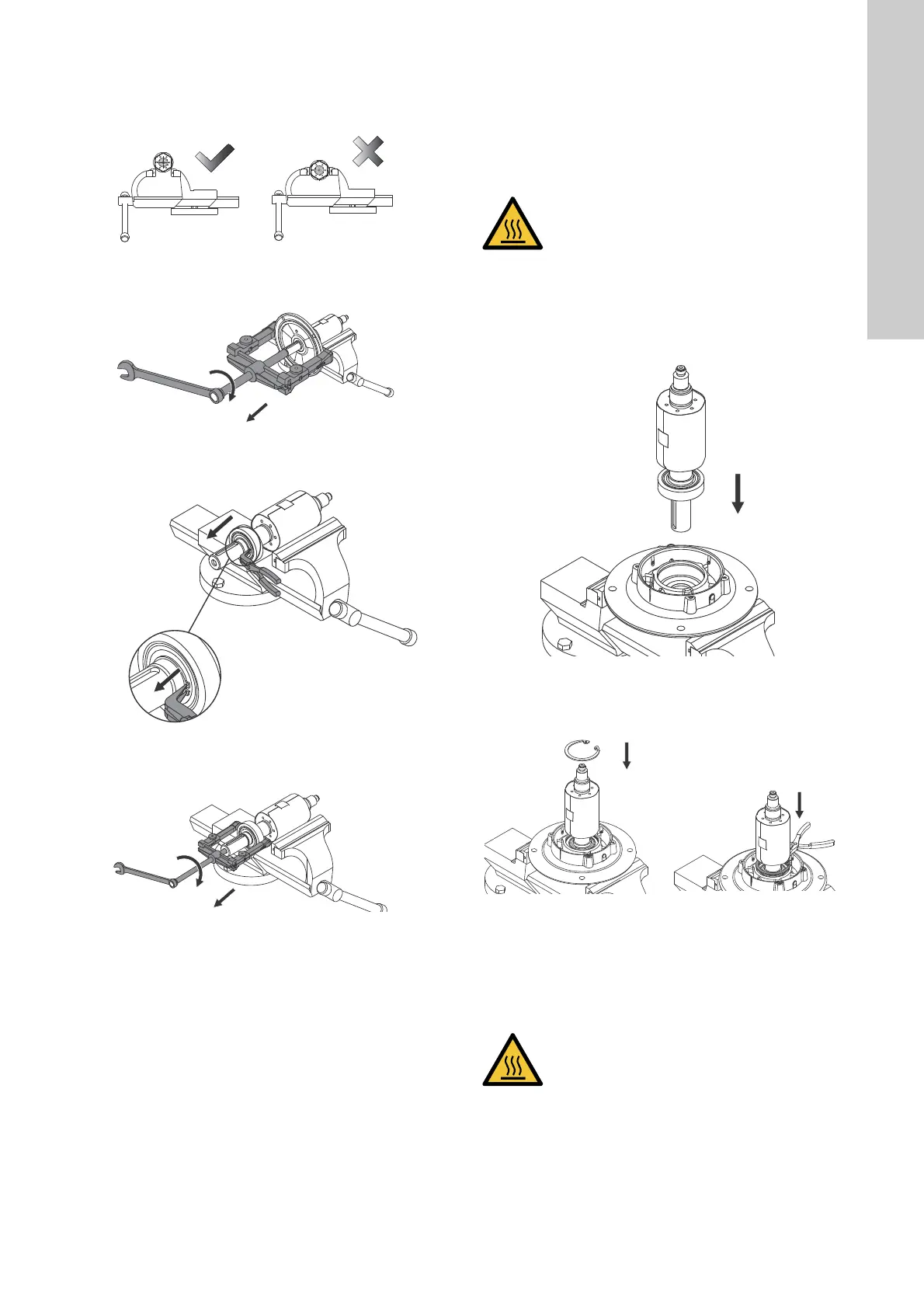

Fig. 19 Fitting the rotor in the flange

9. Fit the locking ring (187) so that the bearing is held by the

flange.

Fig. 20 Fitting the locking ring for the bearing

10. Clean the bearing journal in the non-drive end with a clean

cloth.

11. Heat the bearing (154) to a temperature between 90 and 110

°C.

12. Fit the heated bearing (154) on the shaft (172).

13. Remove the cardboard from the rotor when the bearings have

cooled down.

14. Check that the corrugated spring (158) is correctly fitted in the

stator housing.

15. Apply Loctite 5512 on the flange surface which seals against

the stator.

16. Gently insert the stator onto the rotor.

TM06 9031 1617TM06 9031 1617TM06 9033 1617TM06 9035 1617

CAUTION

Hot surface

Minor or moderate personal injury

- Use heat-resistant gloves.

TM06 9040 2016TM06 9042 1617 - TM06 9043 1617

CAUTION

Hot surface

Minor or moderate personal injury

- Use heat-resistant gloves.

Loading...

Loading...