2

The EnDat interface provides everything

needed to reduce system cost and at the

same time improve your technical standard.

The most significant benefits are:

Cost optimization

• A single interface for all absolute and

incremental encoders

• Simple subsequent electronics with

EnDat receiver chip and standard

components

• Simpler, more economical voltage

supply, since remote sensing is not

required

• Simple connection technology: Standard

connecting elements (M12 – 8-pin),

single shielded standard cables and low

wiring costs

• Only one cable with HMC 6: the Hybrid

Motor Cable contains the lines for the

encoder, the motor and the brake

• Small motor or system dimensions

through compact connecting elements

• No expensive additional sensory analysis

and wiring: EnDat 2.2 transmits additional

data (limit switch, temperature, etc.)

• Faster configuration during installation:

Datum shifting through offsetting by a

value in the encoder

Improved quality

• Higher system accuracy through specific

optimization in the encoder

• High contour accuracy, particularly for

CNC machine tools: position value

formation in the encoder permits shorter

sampling intervals without influencing

the computing time of the CNC

Higher availability

• Automatic configuration of the system

axis: all necessary information can be

saved in the encoder (electronic ID label).

• High system reliability through purely

digital data transmission

• Diagnostics of the encoders through

monitoring messages and warnings that

can be evaluated in the subsequent

electronics

• High transmission reliability through

cyclic redundancy checking

Safety system

• EnDat 2.2 was conceived for safety-

related machine designs up to SIL 3

• Two independent position values for

error detection

• Two independent error messages

• Checksums and acknowledgments

• Forced dynamic sampling of error

messages and CRC formation by

subsequent electronics

Support for state-of-the-art machine

designs

• Suitable for direct drive technology

thanks to high resolution, short cycle

times and commutation information

• Cyclic sampling every 25 µs with full

“read and write” mode

• Position values available in the subse-

quent electronics after only approx. 10 µs

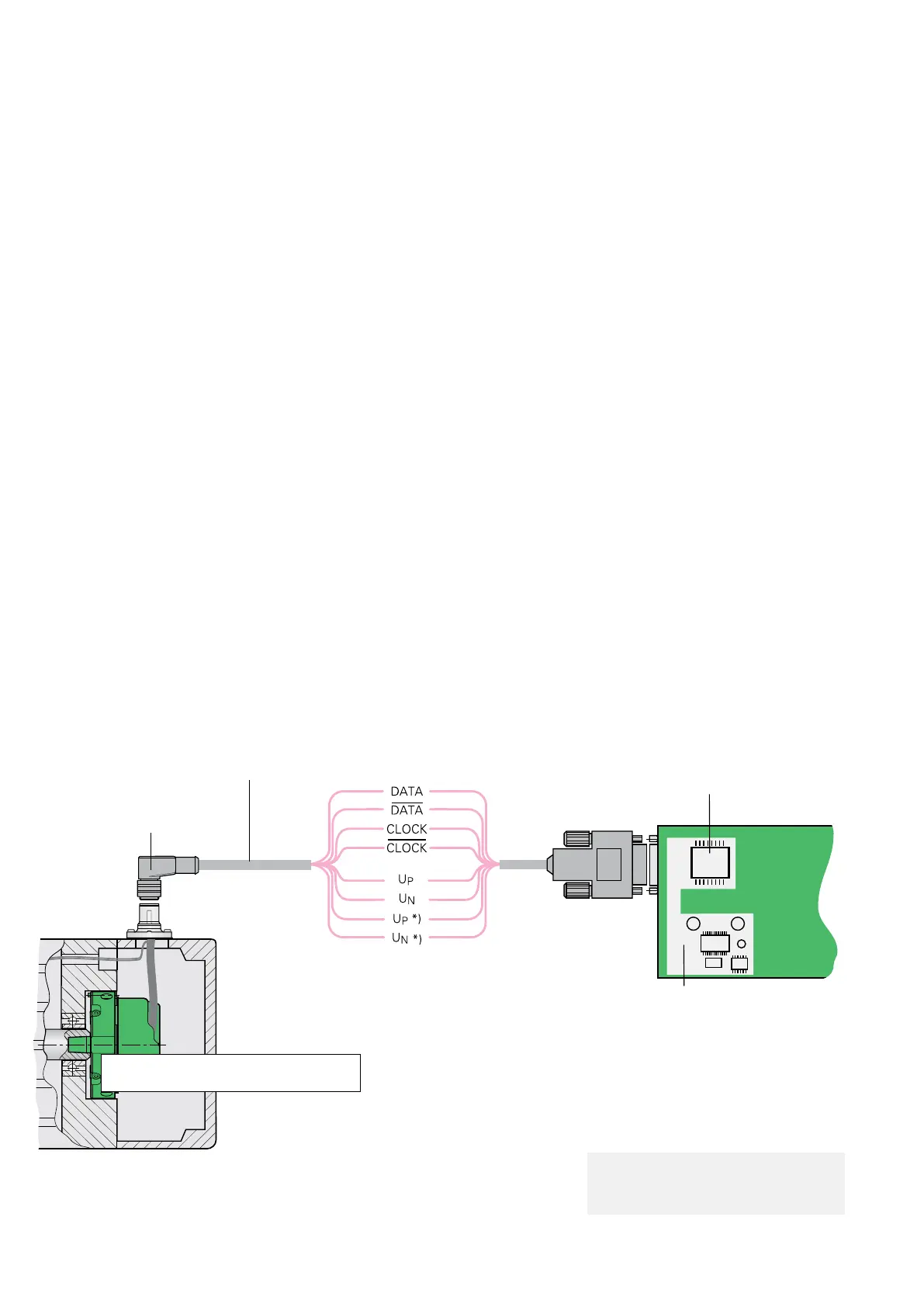

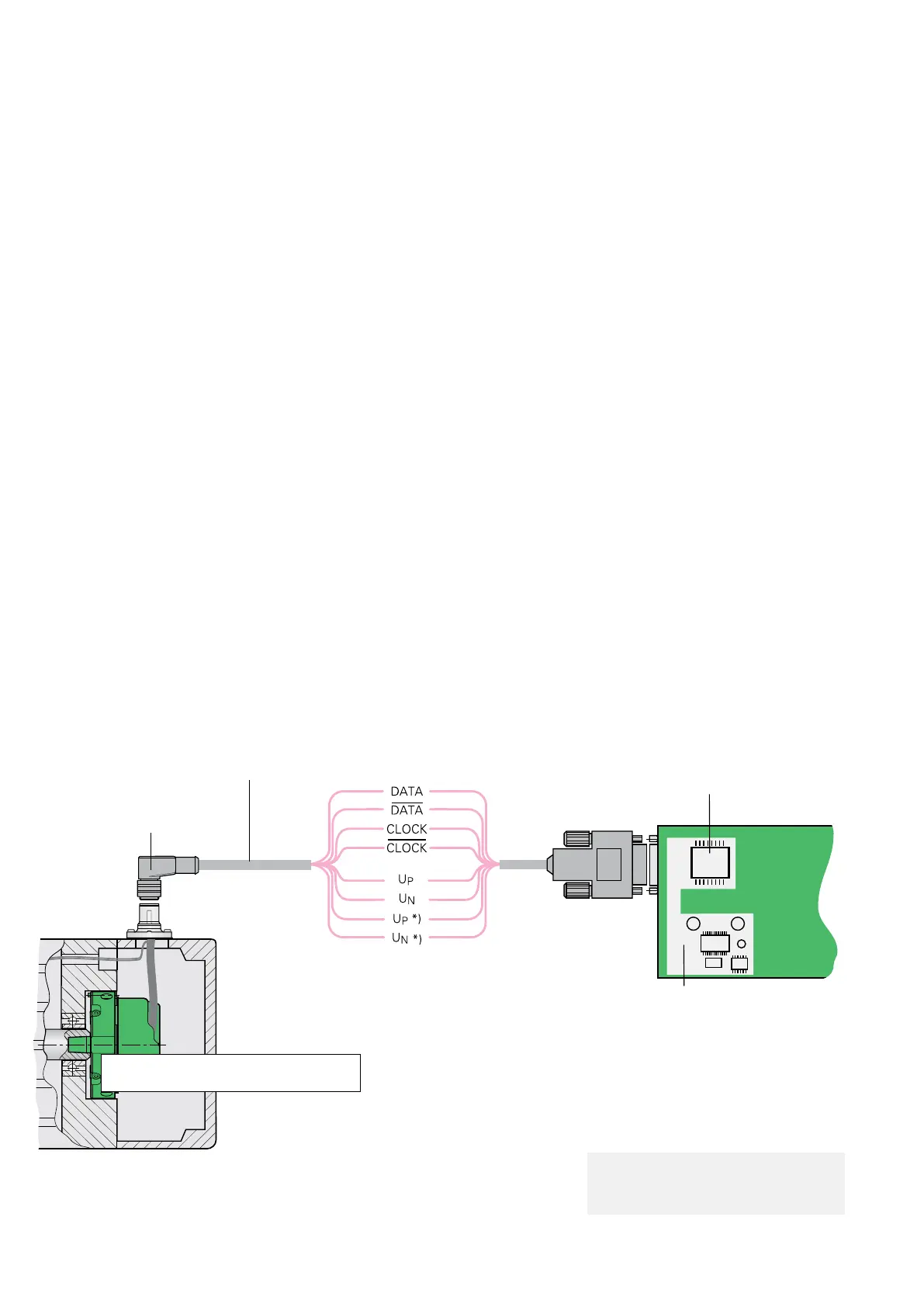

Miniature connecting

element, M12, 8-pin

Simple connection technology,

8-wire cable, single shielding

Integrated interpolation and position value

formation, temperature measurement

Connecting element,

e.g. M12, D-sub

Voltage supply without

remote sensing

(U

P

= 3.6 to 5.25 V or

3.6 to 14 V)

Simple subsequent electronics

with EnDat 2.2 receiver chip

(“EnDat Master”)

* For parallel voltage supply lines

or battery buffering

Benefits of the EnDat interface

For further information on implementing

EnDat or additional documents, see

www.endat.de

Loading...

Loading...