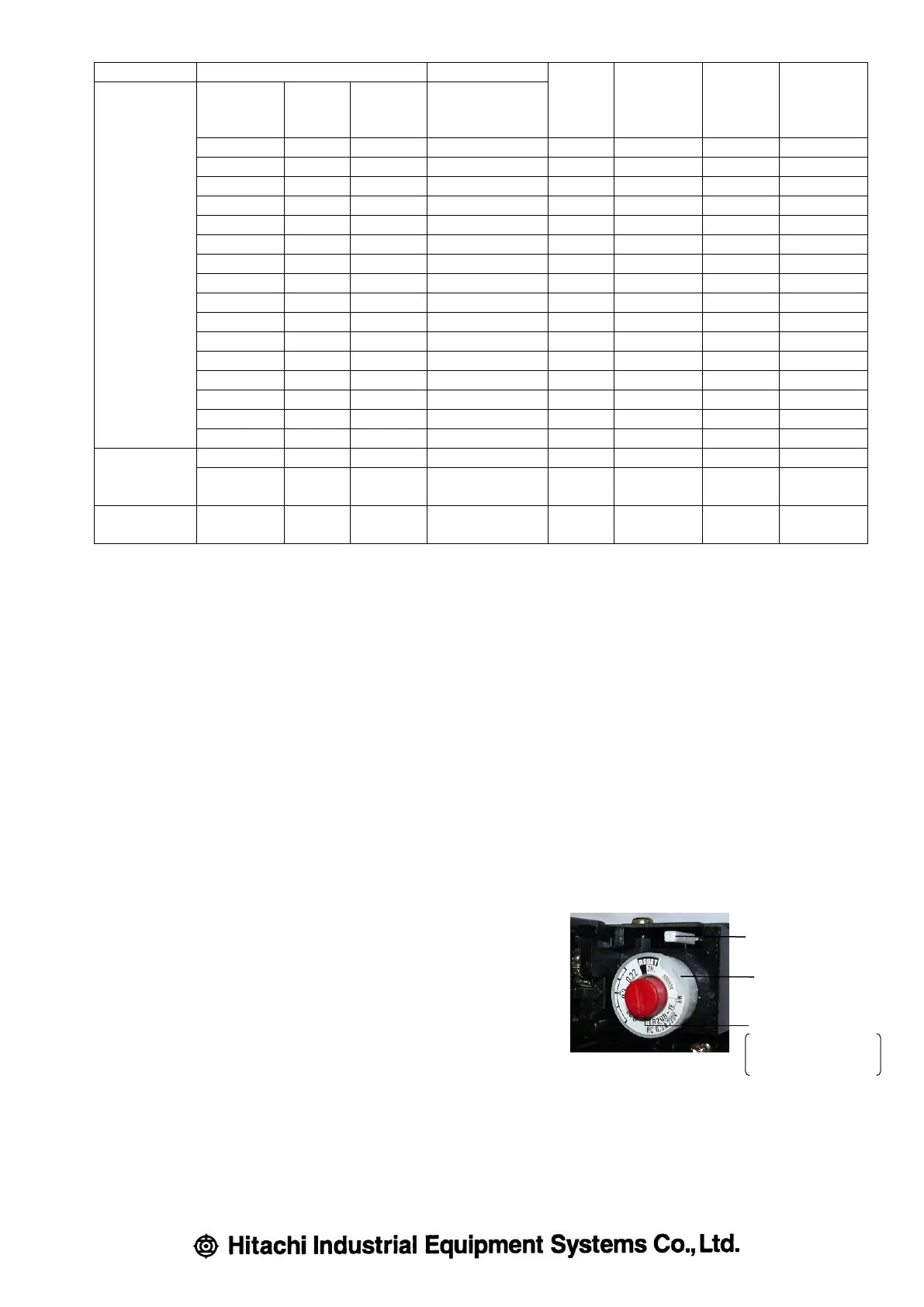

Table2 Wire size and tightening torque

Even a terminal screw of the same size is different from Contactor and Thermal Relay.

Please be careful so that screws are not replaced on the occasion of wiring.

When do not use an appropriate screw, it is not tightened, and a case may be damaged.

4.Using

Normal service condition

(1) Ambient temperature :-5℃ to 40℃ (usable up to 50℃ without enclosure)(HS series is 55℃)

(2) Relative humidity :45% to 85%

(3) Altitude :2,000m or lower

(4) Atmosphere :must be free from corrosive gas, combustible gas, dust, vapor, salt, etc.

● Don’t touch electric connecting, or you should be damaged by electric-shock.

● Check the wire is anenergized at the time of maintenance, or you should be damaged by electric-shock.

● Don’t operate with opening a cover of the contactor, or short circuit should be made.

● At using for reversible type, electrical interlock must be needed.

● A metallic case must be connected to the earth.

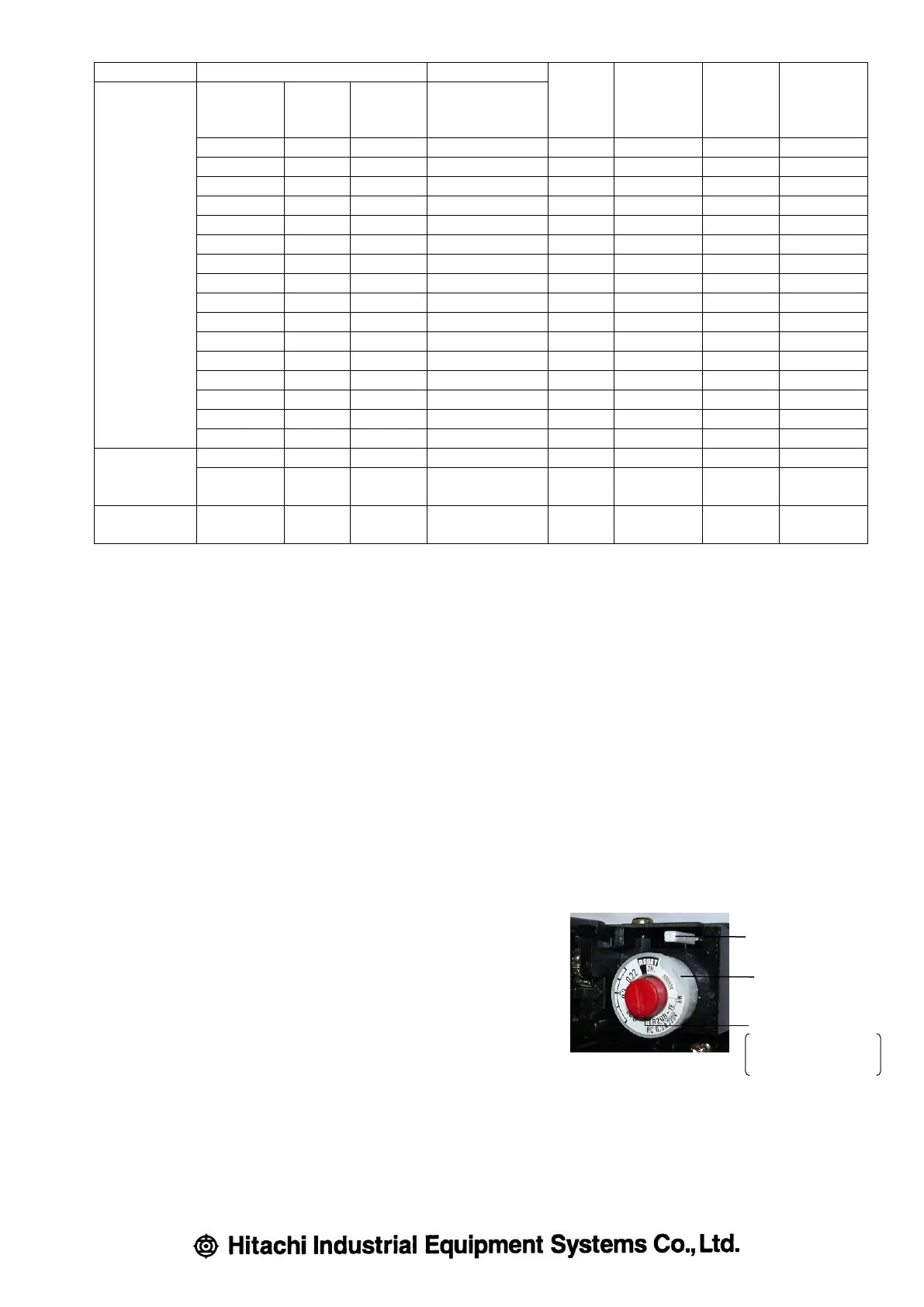

● For thermal overload relay, setting current must be adjusted to rating of motor by turning of current

adjusting knob. Don’t over-turn adjusting knob.

5.Maintenance

● Check whether screw are fully tightened. If a loose, tighten

more.

● Check whether foreign substances such as a washer, wire

waste etc., have infillrated the contactor by manual

operation.

● During trial running, check whether there occurs abnormal

noise, abnormal smell or abnormal arcing etc.

● Check whether contacts are abnormally worn after loosed

screws and removed cover of the contactor.

● Eliminate dropped foreign substances such as dust, chip etc.

on each portion.

● Don’t paint oil on cores of the contactor.

● Even if contacts are somewhat blackened, no trouble occurs.

● Even if only one contact of three phase is worn, the contacts of all phases must be replaced at the same

time.

At replacing, check the wire is anenergized.

● Dust from worn contact should be eliminated after removed the worn contact.

Loading...

Loading...