18

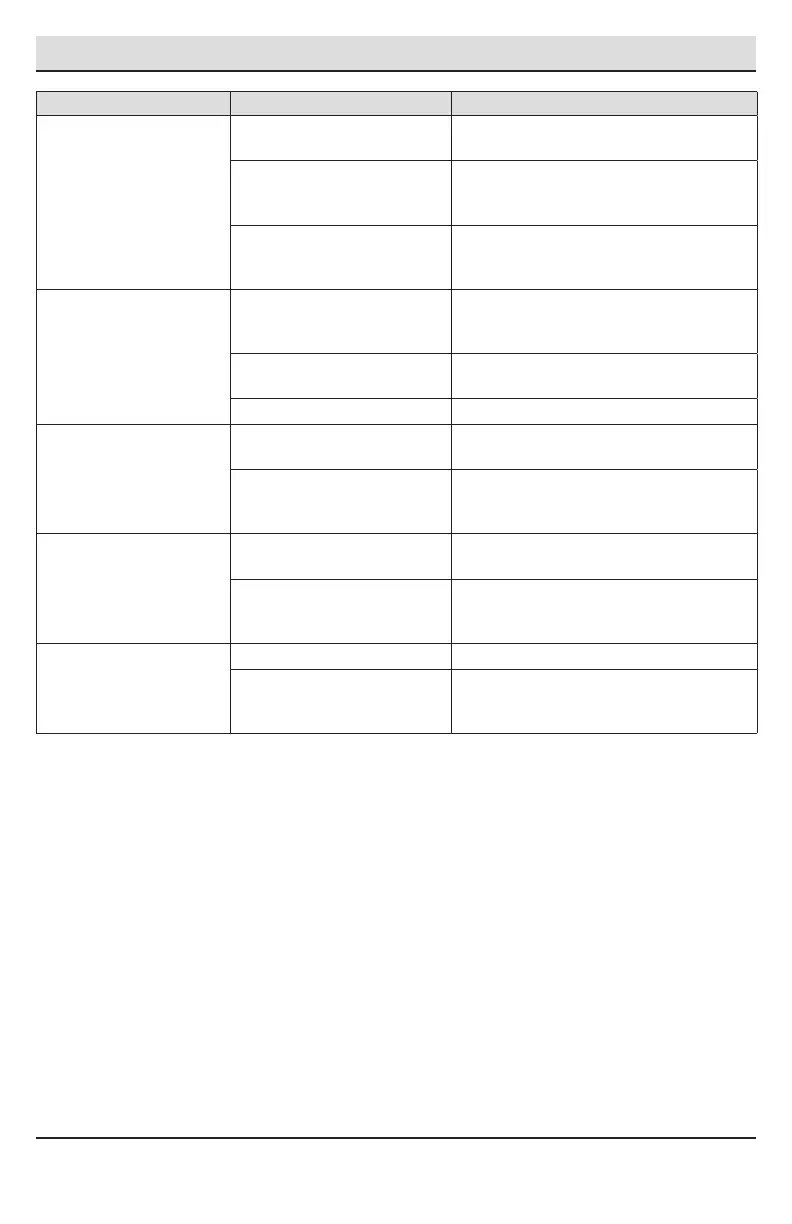

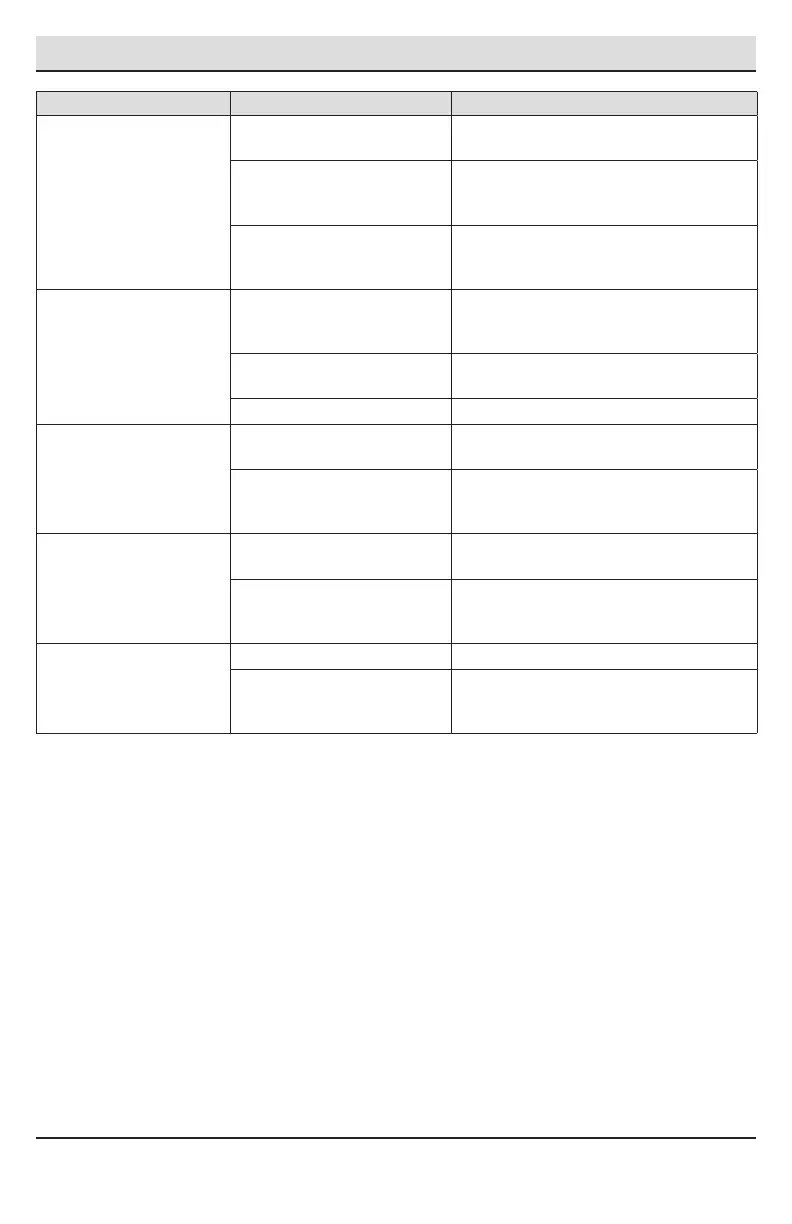

Problem Possible Cause Solution

The thermal overload protector

cuts out repeatedly.

□ There is low voltage from

the power source.

□ Call an electrician.

□ There is a lack of proper

ventilation, or the room

temperature is too high.

□ Move the compressor to a well-ventilated

area.

□ The wrong gauge wire or

length of extension cord is

being used.

□ Check for proper gauge wire and cord

length.

The air receiver pressure

drops when the compressor

shuts off.

□ The connections (fittings,

tubing, etc.) are loose and

leaking.

□ Check all connections with a soap and

water solution and tighten.

□ The drain valve is loose

or open.

□ Tighten the drain valve.

□ The check valve is leaking. □ Bring the compressor to a service center.

There is excessive moisture

in the discharge air.

□ There is excessive water in

the air tank.

□ Drain the tank.

□ The compressor is working

under a high humidity

environment.

□ Move the compressor to an area of less

humidity; use an air line filter.

The compressor

continuously runs.

□ The pressure switch is

defective.

□ Bring the compressor to a service center.

□ An excessive amount of air

is being used.

□ Decrease the air usage; the compressor

is not large enough for the tool’s

requirement.

The air output is lower than

normal.

□ The inlet valves are broken. □ Bring the compressor to a service center.

□ The connections (fittings,

tubing, etc.) are loose and

leaking.

□ Tighten the connections.

Troubleshooting (continued)

Loading...

Loading...