REV C 4-6 121363

• Place the steering control levers in the park brake

position.

• Disengage the deck clutch.

• Remove the ignition switch key.

• Disconnect the negative battery cable.

2. Remove the three 1/4” filter guard screws and filter

guard. Clean any loose debris from around the filter.

Figure 4-12

3. Place an oil drain pan beneath the oil filter and remove

the oil filter from the transaxle.

4. After the oil has been drained, wipe the filter base sur-

face off and apply a film of new oil to the gasket of the

new replacement filter.

5. Install the new filter by hand, turn 3/4 to one full turn

after the filter gasket contacts the filter base surface.

6. Re-install the filter guard with three 1/4” screws.

Torque the screws to 65 in.–lbs. each. Figure 4-12

7. Repeat steps 2–6 for the opposite side transaxle.

8. Drain oil filters of all free flowing oil prior to disposal.

Place used oil in appropriate containers.

9. IMPORTANT: Remove the top port plug from both tran-

saxles prior to filling with oil. This will allow the tran-

saxles to vent during oil fill. Figure 4-13

10. Remove the cap from the transaxle's expansion tank.

11. Fill with 20W50 motor oil until oil just appears at the

bottom of each transaxles top port (approximately 2

qts. per transaxle). Install the top port plug into each

transaxle. Torque plugs to 180 in.–lbs. Clean up any

oil that leaked from the ports. Figure 4-13

12. Continue to fill the transaxles through the expansion

tank until the “Full Cold” line is reached on the expan-

sion tank.

13. Re-install the expansion tank cap by hand. Be careful

not to overtighten.

14. Proceed to the purge procedure.

IMPORTANT: Purging procedures must be followed after

changing the oil and filter. Refer to the Purging Procedure sec-

tion for detailed information.

IMPORTANT: When washing the mower, direct the spray

away (especially if using a power washer) from the transaxle’s

seals to prevent water intrusion and to ensure component per-

formance.

Purging Procedure

Due to the effects air has on efficiency in hydrostatic drive

applications, it is critical that air is purged from the system.

A. Expansion tank

Figure 4-10

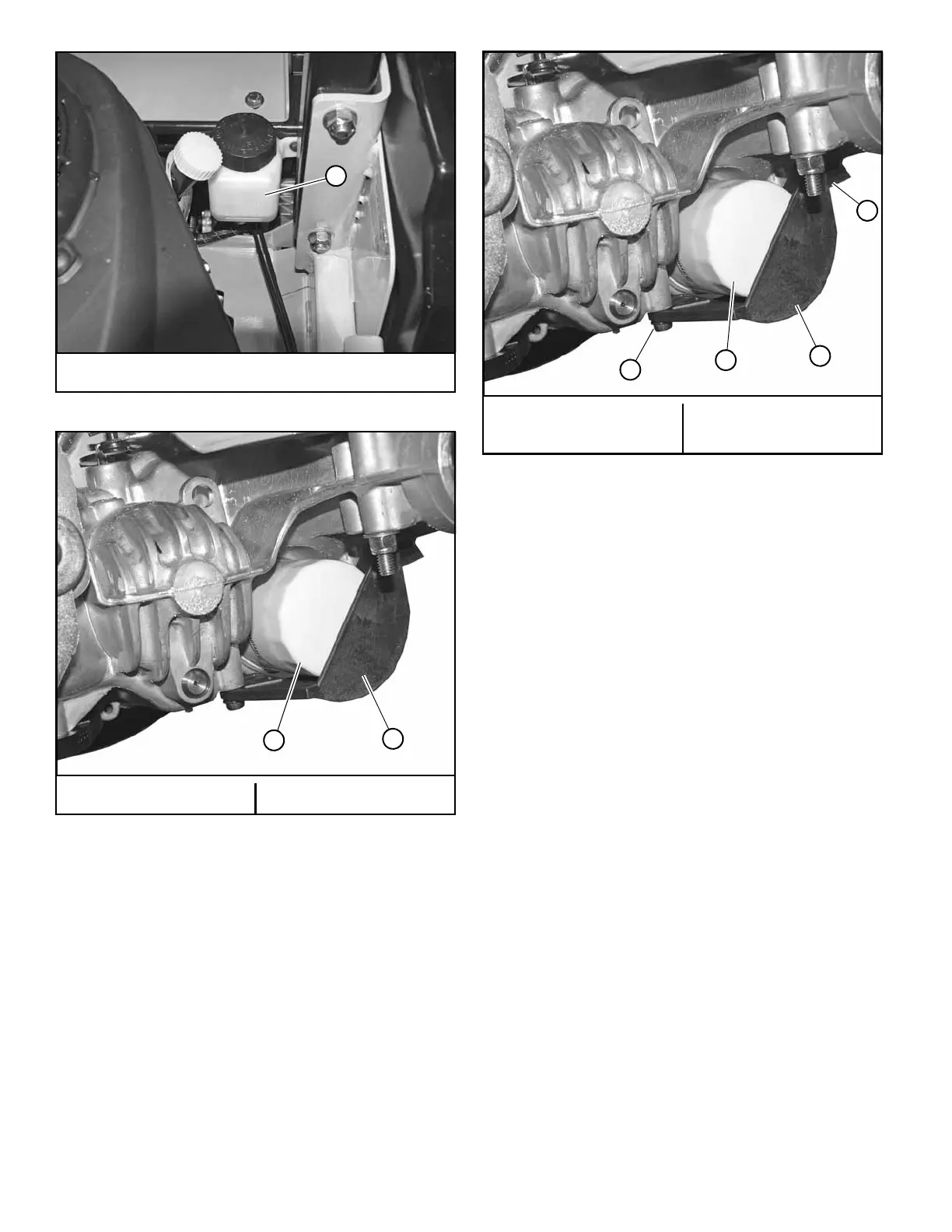

A. Filter B. Filter guard

Figure 4-11

A. Screw

B. Filter

C. Filter guard

Figure 4-12

Loading...

Loading...