Power supply control board settings

2 Field Service Bulletin

HPR CONTROL BOARD REPLACEMENT

DIP switch location and settings

The dip switches on the new board must match the dip

switches on the old board.

Switch number 1 determines if the board is being used in

an HPR130 (OFF position) or an HPR260 (ON position).

Switches 2 and 3 are used when the plasma system has

more than one power supply in series (also referred to as

multi-drop systems). Switches 4 through 8 must be in the

OFF position. See the wiring diagrams in your instruction

manual for more information on multi-drop systems).

= HPR130

= HPR260

Caution: Do not discard the old control board until the installation is complete.

All jumpers and dip switches on the new control board must match the

settings on the old control board for the system to work correctly.

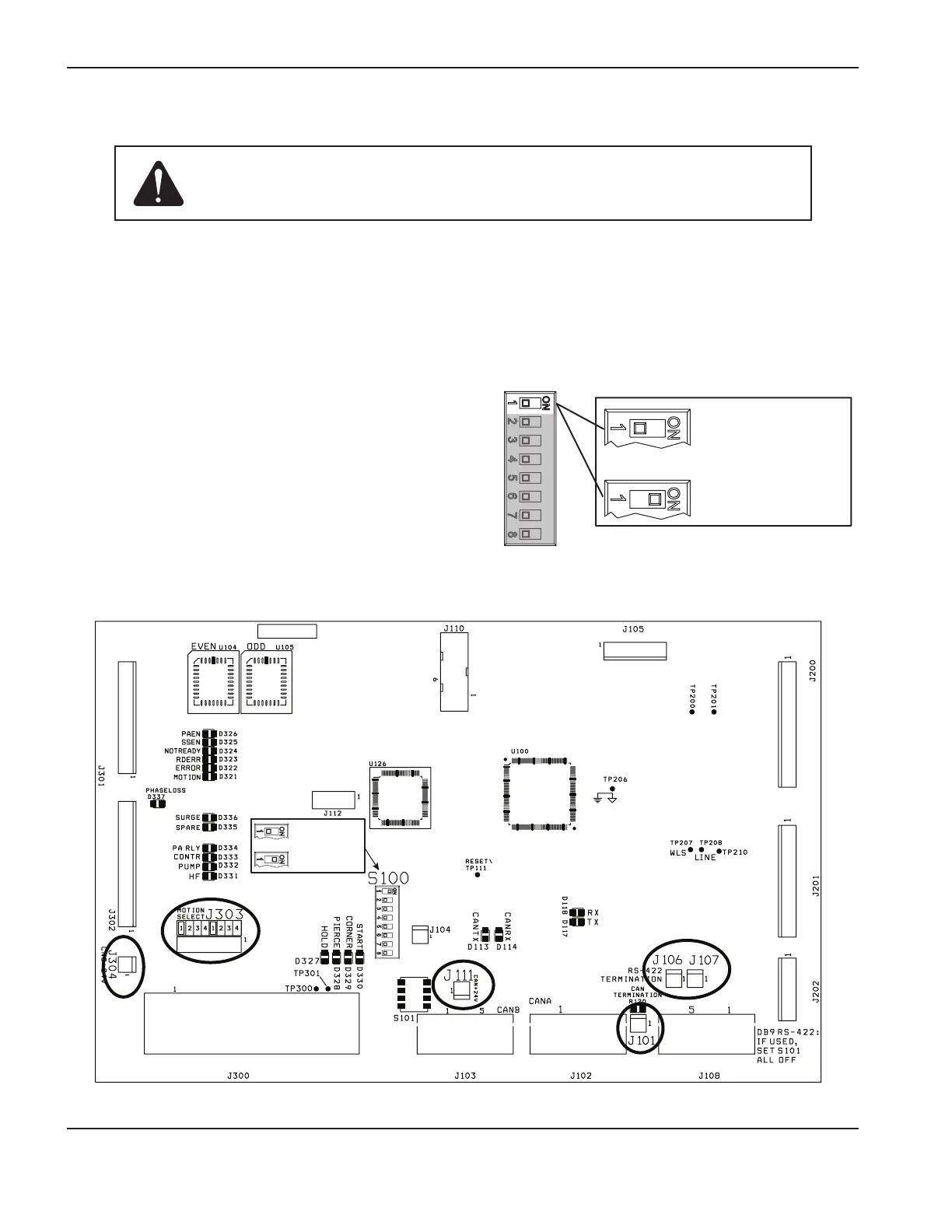

Jumpers

The jumpers on the new control board must match the jumpers present on the old control board. Configure the jumpers

on the new control board to match the jumpers on the old control board in the corresponding locations. See the figure

below for jumper locations.

041993

HPR130XD and HPR260XD power supply control board

= HPR130

= HPR260

Loading...

Loading...