2 3

Recommended cut capacity – handheld

Powermax65 SYNC

Cut speed Material thickness

500mm/min (20in/min) 19mm (3/4inch)

250mm/min (10in/min) 25mm (1inch)

125mm/min (5in/min) – severance 32mm (1-1/4inch)

Pierce capacity 16mm (5/8inch)

Powermax85SYNC

Cut speed Material thickness

500mm/min (20in/min) 25mm (1inch)

250mm/min (10in/min) 32mm (1-1/4inch)

125mm/min (5in/min) – severance 38mm (1-1/2inch)

Pierce capacity 19mm (3/4inch)

Powermax105SYNC

Cut speed Material thickness

500mm/min (20in/min) 32mm (1-1/4inch)

250mm/min (10in/min) 38mm (1-1/2inch)

125mm/min (5in/min) – severance 51mm (2inches)

Pierce capacity 22mm (7/8inch)

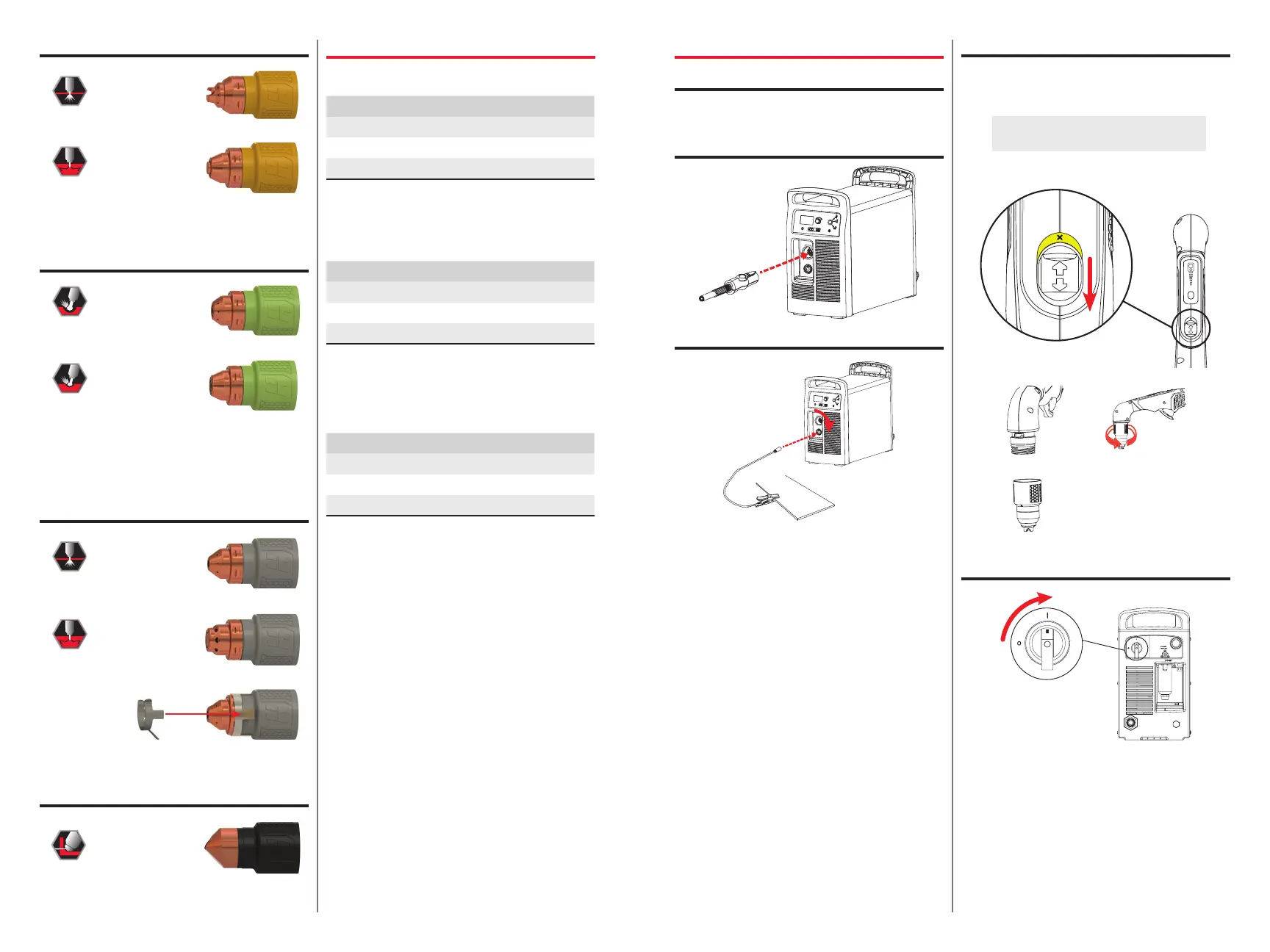

Operate the system

Before you use the system

1. Connect the gas supply to the plasma power supply.

2. Connect the plasma power supply to electrical power.

Step 1 – Connect the torch lead

Step 2 – Connect the work lead and work clamp

1/4turn until locked

in position

Step 3 – Install the cartridge

SmartSYNC™ torches have a switch that locks the torch.

This prevents the torch from firing even if the plasma power

supply is ON.

The SmartSYNC mini machine torch does not

have a switch that locks the torch.

Lock the torch before you install a new cartridge.

1/4 turn to install

Step 4 – Set the power switch to ON(I)

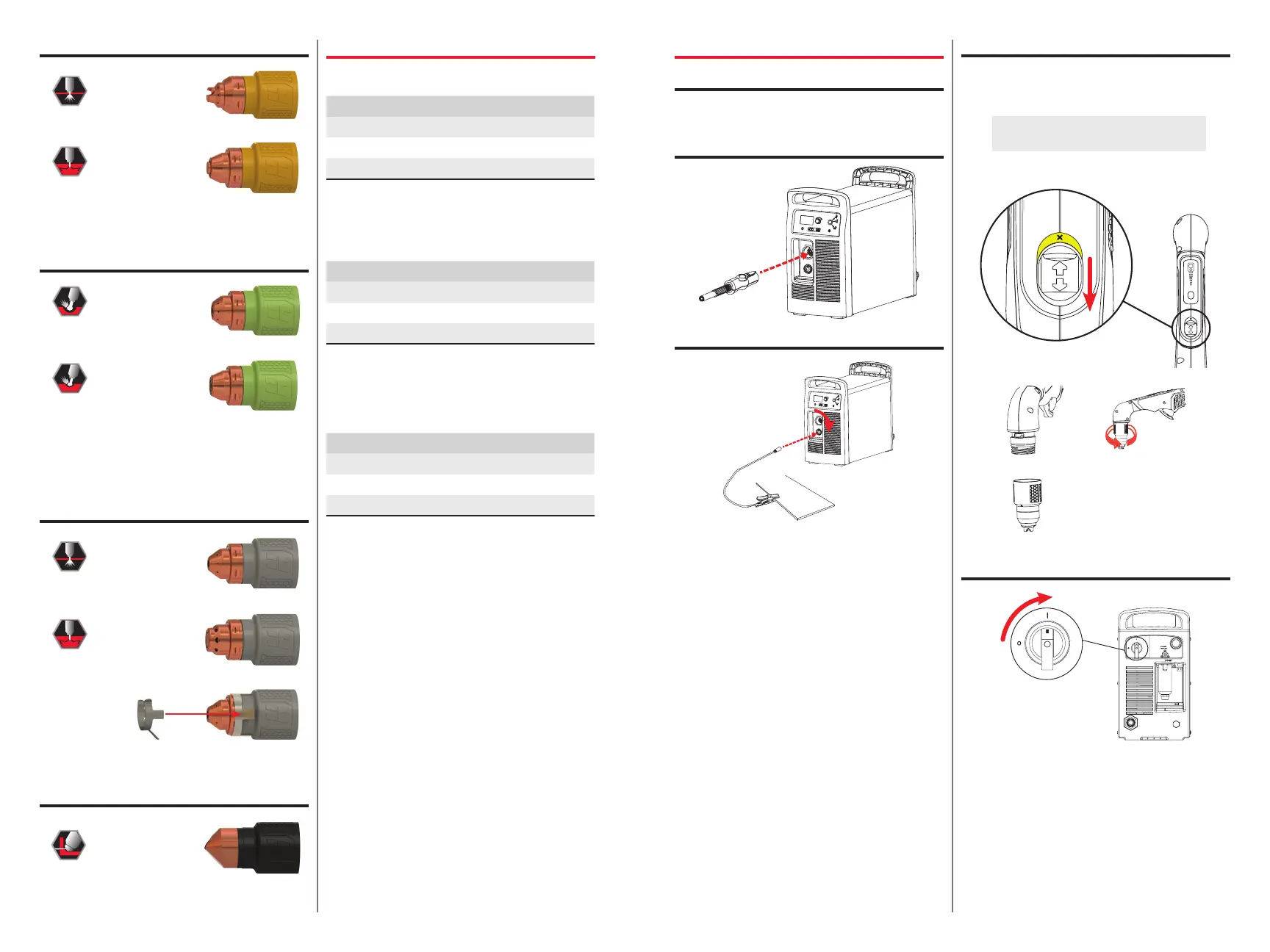

Hand cutting cartridges

30 A – 45 A: 428928

105 A: 428938

45A – 85 A: 428932

105 A: 428939

45 A – 85 A: 428933

105 A: 428937

85 A: 428935

65 A: 428931

45 A: 428927

30 A – 45 A: 428926

105 A: 428936

85 A: 428934

65 A: 428930

45 A: 428925

428895

ohmic sensing ring (420580), 3 per kit

Gouging cartridges

Mechanized cutting cartridges

Drag cutting

FineCut

Max Removal

gouging

Max Control

gouging

Mechanized

cutting

FineCut

FlushCut cartridges

105 A: 428954

85 A: 428953

65 A: 428952

FlushCut

Loading...

Loading...