Printed in Japan

© 2016–2018 Icom Inc

Basic Issue: May 10/16

Revision 6: Feb 9/18

12421 Willows Road NE, Kirkland, WA 98034, U.S.A

Printed on recycled paper with soy ink.

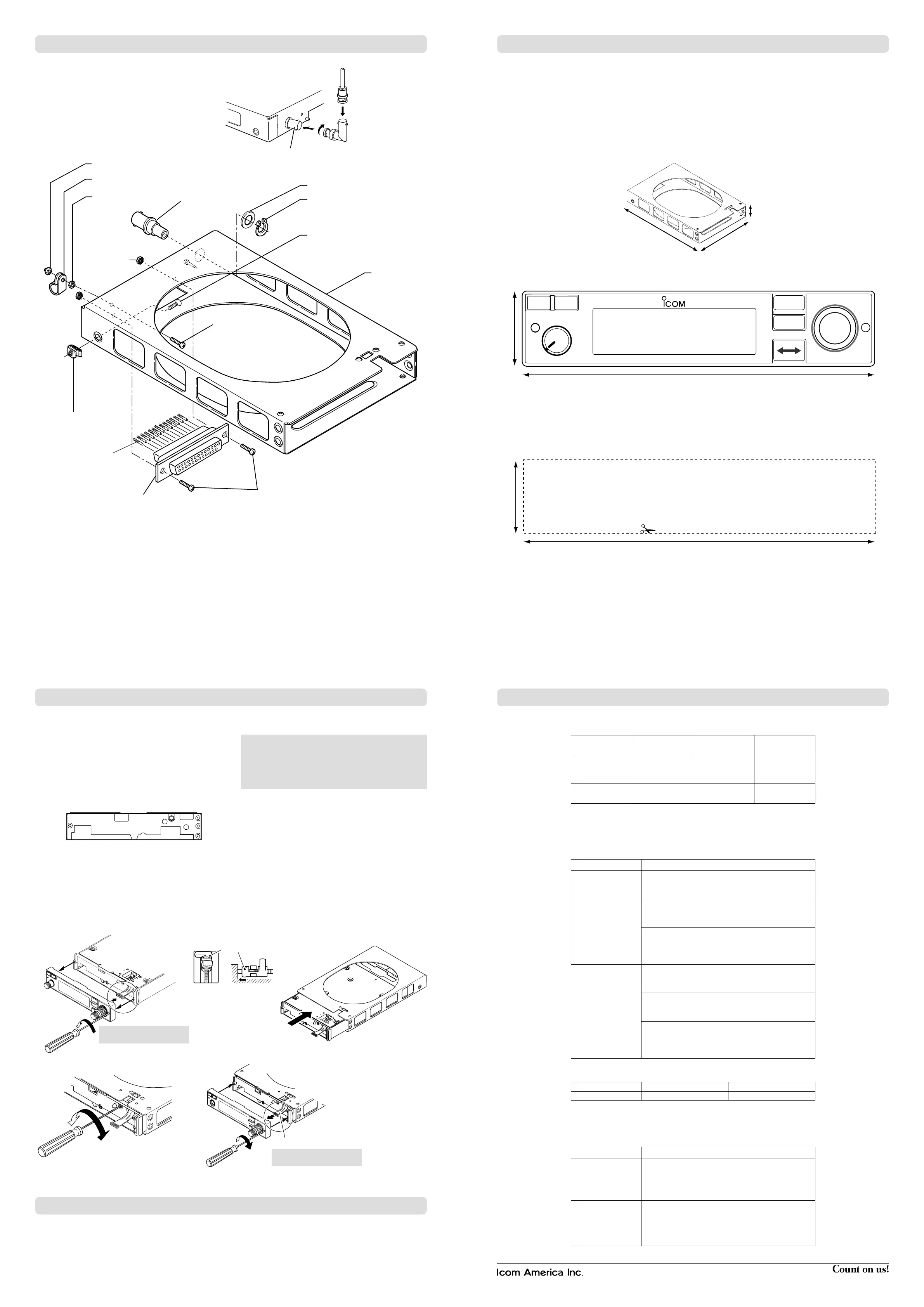

L-type BNC

connector

(User supplied, if required)

Coaxial

connector

y BNC-LP

y BNC-LP

!2 Nut

o Antenna cable clip

!0 Self-crimping nut

u Washer

i C-shaped ring

!4 Screws

!1 Screw

r Screws Bind UNC

q Mounting

bracket

w D-sub 25 pin connector

!3 Crimp nut

q Mounting

bracket

e Connector pins

t K-Lock Nut

. MOUNTING BRACKET ASSEMBLY

D Notes for marking the mounting hole

The transceiver can be mounted securely in the supplied

mounting bracket.

Remember to allow adequate space for installation of

cables and connectors.

When installing two or more transceivers in a stack, the

mounting bracket should be 1.3 mm

(0.05″) apart.

The mounting bracket has 0.6 mm

(0.024″) dimples in the

top, bottom, and both sides for proper spacing.

Mark and cut the mounting holes.

To support the mounting bracket, the rear mounting bosses

should be attached to the airframe.

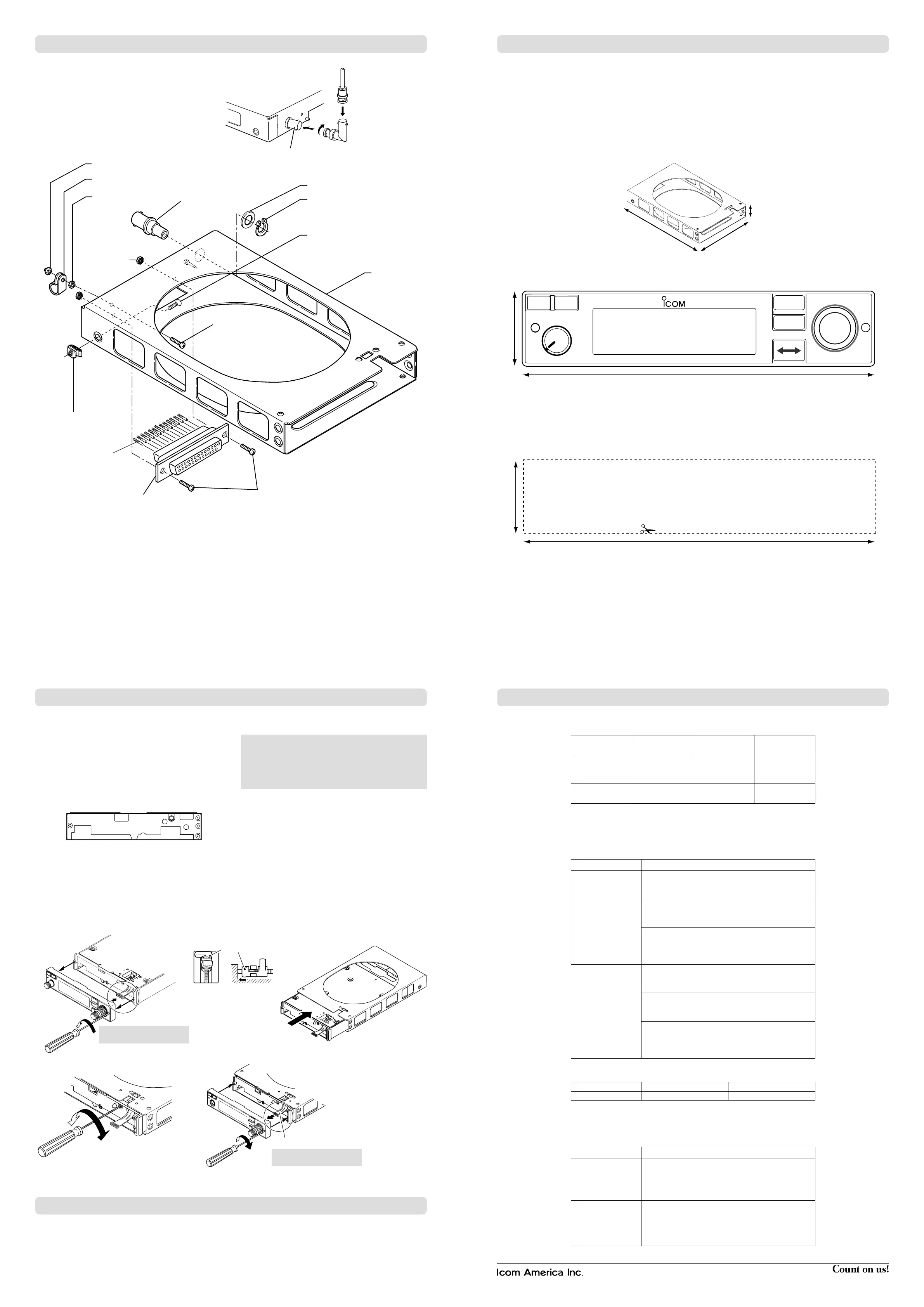

⁄0 MARKING A MOUNTING HOLE

D Mounting bracket dimensions

160 mm (6.3″)

33 mm (1.3″)

260 mm (10.2″)

D Front panel dimensions

160 mm (6.3″)

34 mm (1.3″)

RCL

MEM

OFF

VOL

PUSH

TEST

COMM

DUAL

EC

118.00

128.10

Allow space for the front panel as shown above.

D Template

Cut out dimensions for the mounting bracket as follows.

160 mm (6

5

⁄

16

″)

33 mm (1

5

⁄

16

″)

Fig. 1

Fig. 4

Fig. 3

Fig. 5

Fig. 1

Fig. 6Fig. 5

Fig. 7

Clockwise: For installation.

Counterclockwise: For removal.

CAUTION: Treat the cable with

care when disconnecting it.

Clockwise: For attaching.

Counterclockwise: For removal.

Cable

CAUTION: Treat the cable with

care when connecting it.

Fig. 2

Surface

The flat cable

Fig. 2 Fig. 4Fig. 3

Screw 4 revolutions Unscrew a quarter

revolution

• Metal catch position

Metal catch

Metal catch

⁄1 MOUNTING TO THE BRACKET ⁄3 INFORMATION

D Transceiver installation

1. Remove the front panel from the transceiver’s main unit.

- Use a

3

⁄32″ allen driver.

- Carefully disconnect the cable from the front panel.

(Fig. 1)

2. Insert a

3

⁄32″ allen driver into the lock screw and rotate

the driver counterclockwise until the metal catch

touches the back of the lock chassis. (Fig. 2)

Main unit front view

3. Insert the main unit (transceiver) into the mounting

bracket. (Fig. 3)

4. Turn the lock screw clockwise until the main unit

(transceiver) is fixed to the bracket. (Fig. 4)

5. Connect the cable. (Fig. 5)

6. Attach the front panel and tighten the allen screws.

(Fig. 5)

CAUTION: Make sure that the cable between the

transceiver and front panel is securely connected. The

transceiver may not function properly when loose or when

a wrong connection is made.

Improper cable connection can cause damage and result

in a non-warranty repair.

D Transceiver removal

The transceiver can be easily removed from the mounting

bracket, if required.

1. Remove the front panel from the transceiver's main unit.

- Use a

3

⁄32″ allen driver.

- Carefully disconnect the cable from the front panel.

2. Insert a

3

⁄32″ allen driver into the lock screw and rotate

the driver counterclockwise until the metal catch

touches the back of the lock chassis.

3. Slowly pull the transceiver out from the mounting bracket.

4. Connect the cable to the front panel.

5. Attach the front panel and tighten the allen screws.

D TSO Authorization Reference

Function TSO/RTCA

Applicable SW

P/Ns

DO-178C Level

Equipment That

Prevents Blocked

Channels

TSO-C128a

DO-207

A220-0615-0028 C

COM Transceiver

TSO-C169a

DO-186B

A220-0615-0028 C

(1) Software Part Number

(

A220-0615

) - ( 0028 )

(Part Number) - (Version) Version to be incremented on a minor software change

D TSO Deviation list

TSO/ETSO Deviation

TSO-C128a

1. Icom was granted a deviation from the TSO to mark

the exterior of the unit with the serial number instead

of the date of manufacture.

2. Icom was granted a deviation from the TSO to use

RTCA/DO-160G instead of the earlier version as the

standard for environmental conditions and tests.

3. Icom was granted a deviation from the TSO to use

RTCA/DO-178C instead of the earlier version to

demonstrate compliance for the verification and

validation of computer software.

TSO-C169a

1. Icom was granted a deviation from the TSO to mark

the exterior of the unit with the serial number instead

of the date of manufacture.

2. Icom was granted a deviation from the TSO to use

RTCA/DO-160G instead of the earlier version as the

standard for environmental conditions and tests.

3. Icom was granted a deviation from the TSO to use

RTCA/DO-178C instead of the earlier version to

demonstrate compliance for the verification and

validation of computer software.

• FCC Grant of Equipment Authorization

Model FCC ID IC ID

IC-A220 AFJ297410 202D-297410

D Non-TSO function list

These functions operate per the system requirements for this transceiver and do not interfere with the TSO MOPS compliance.

Function Description

Weather Channels

Reception

The radio provides reception of the weather channels

which Icom America evaluated as part of the RTCA/

DO-160G and RTCA/DO-178C test/verication process

and additional system level tests were also performed.

Two Station Intercom

The radio provides a user interface to select two

station intercom as an option to the pilot. This function

was tested as part of the RTCA/DO-160G and the

RTCA/DO-178C test/verication process and additional

system level tests were also performed.

Check the following points after transceiver installation.

- Polarity of the power supply.

- NO interference caused to other equipment.

- NO noise or interference from other equipment.

- VSWR is less than 2.5:1.

- Communication capability on both the highest and lowest

communication frequencies, if possible.

⁄2 OPERATION CHECK

Loading...

Loading...