30 http://air.ingersollrand.com

INSTALLATION / HANDLING OPERATION AND MAINTENANCE MANUAL

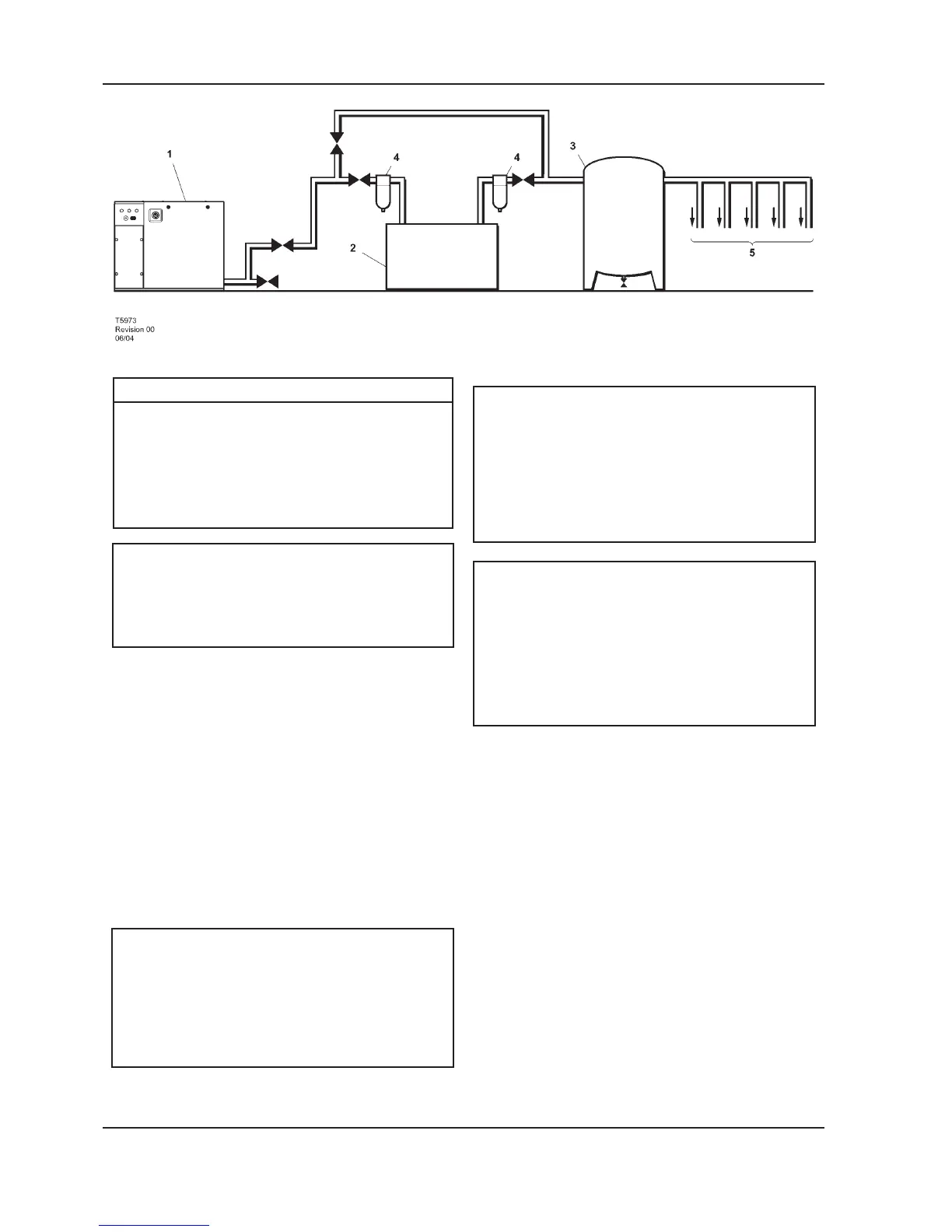

KEY

Compressor

Air Receiver

Air Dryer

Compressed air lters

System demand points

1.

2.

3.

4.

5.

NOTE

Items [2] to [5] are optional or may be existing

items of plant. Refer to your Ingersoll Rand

distributor / representative for specic

recommendations.

LOCATION IN THE PLANT

The compressor can be installed on any level oor

capable of supporting it. A dry, well ventilated area

where the atmosphere is clean is recommended. A

minimum of 1m (3ft) should be left all around machine

for adequate service access and ventilation.

Adequate clearance needs to be allowed around and

above the machine to permit safe access for specied

maintenance tasks.

Ensure that the machine is positioned securely and on

a stable foundation. Any risk of movement should be

removed by suitable means, especially to avoid strain on

any rigid discharge piping.

CAUTION

Screw type compressors [1] should not be

installed in air systems with reciprocating

compressors without means of isolation such

as a common receiver tank. It is recommended

that both types of compressor be piped to a

common receiver using individual air lines.

CAUTION

The use of plastic bowls on line lters and other

plastic air line components can be hazardous.

Their safety can be aected by either synthetic

coolants or the additives used in mineral oils.

Ingersoll Rand recommends that only lters

with metal bowls should be used on any

pressurised system.

CAUTION

The standard compressor unit is not suitable

for operation in temperatures liable to cause

freezing as Condensate water is liable to be

produced in the after cooler and receiver where

tted.

Refer to your Ingersoll Rand distributor for

further information.

DISCHARGE PIPING

Discharge piping should be at least as large as the

discharge connection of the compressor. All piping

and ttings should be suitably rated for the discharge

pressure.

It is essential when installing a new compressor [1],

to review the total air system. This is to ensure a safe

and eective total system. One item which should be

considered is liquid carryover. Installation of air

dryers [3] is always good practice since properly selected

and installed they can reduce any liquid carryover to

zero.

It is good practice to locate an isolation valve close to

the compressor and to install line lters [4].

It is a requirement for air dryers covered under AirCare

that correctly sized Ingersoll Rand pre and afterlters

are installed.

Loading...

Loading...