GENERAL INFORMATION 21

MAINTENANCE

1. VALVE CLEARANCE AND ADJUSTMENT

Note:

The cylinder head bolts were previously tightened with

the “Angular Tightening Method”. Therefore, it is not

necessary to retighten the cylinder head bolts before

adjusting the valve clearance.

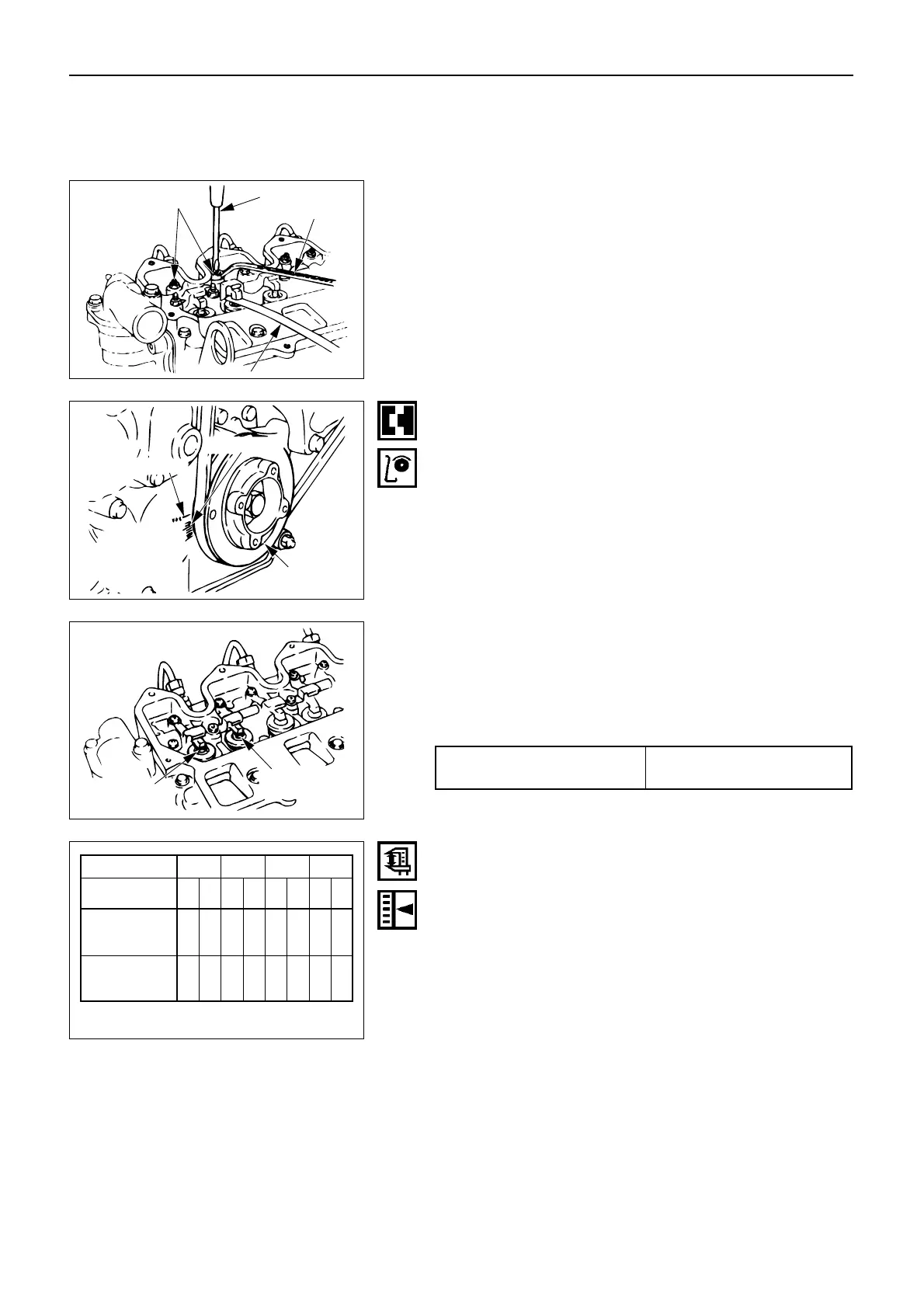

1. Bring the piston in either the No. 1 cylinder or the

No. 3 cylinder to Top Dead Center on the compres-

sion stroke by turning the crankshaft until the TDC

mark on the front cover aligns with the groove mark

on the crankshaft pulley.

2. Check to see if there is play in the No. 1 intake and

exhaust valve rocker arms.

If the No. 1 cylinder intake and exhaust valve rocker

arms have play, the No. 1 piston is at TDC on the

compression stroke.

If the No. 1 cylinder intake and exhaust valve rocker

arms are depressed, the No. 4 piston is at TDC on

the compression stroke.

Adjust the circle or double circle marked valves as

shown in Fig. 24, while the No. 1 or the No.4 cylin-

der is at TDC on compression stroke.

mm (in.)

Intake and Exhaust

Valve Clearance (cold)

0.40 ± 0.05 (0.015 ± 0.002)

3. Loosen each valve clearance adjusting screw as

shown in the illustration.

4. Insert a 0.40 mm (0.015 in) feeler gauge between the

rocker arm and the valve stem end.

5. Turn the valve clearance adjusting screw until a

slight drag can be belt on the feeler gauge.

6. Tighten the lock nut securely.

7. Rotate the crankshaft 360°.

Realign the crankshaft pulley.

8. Adjust the clearances for the remaining valves as

shown in the illustration.

Loading...

Loading...