38 - Maintenance

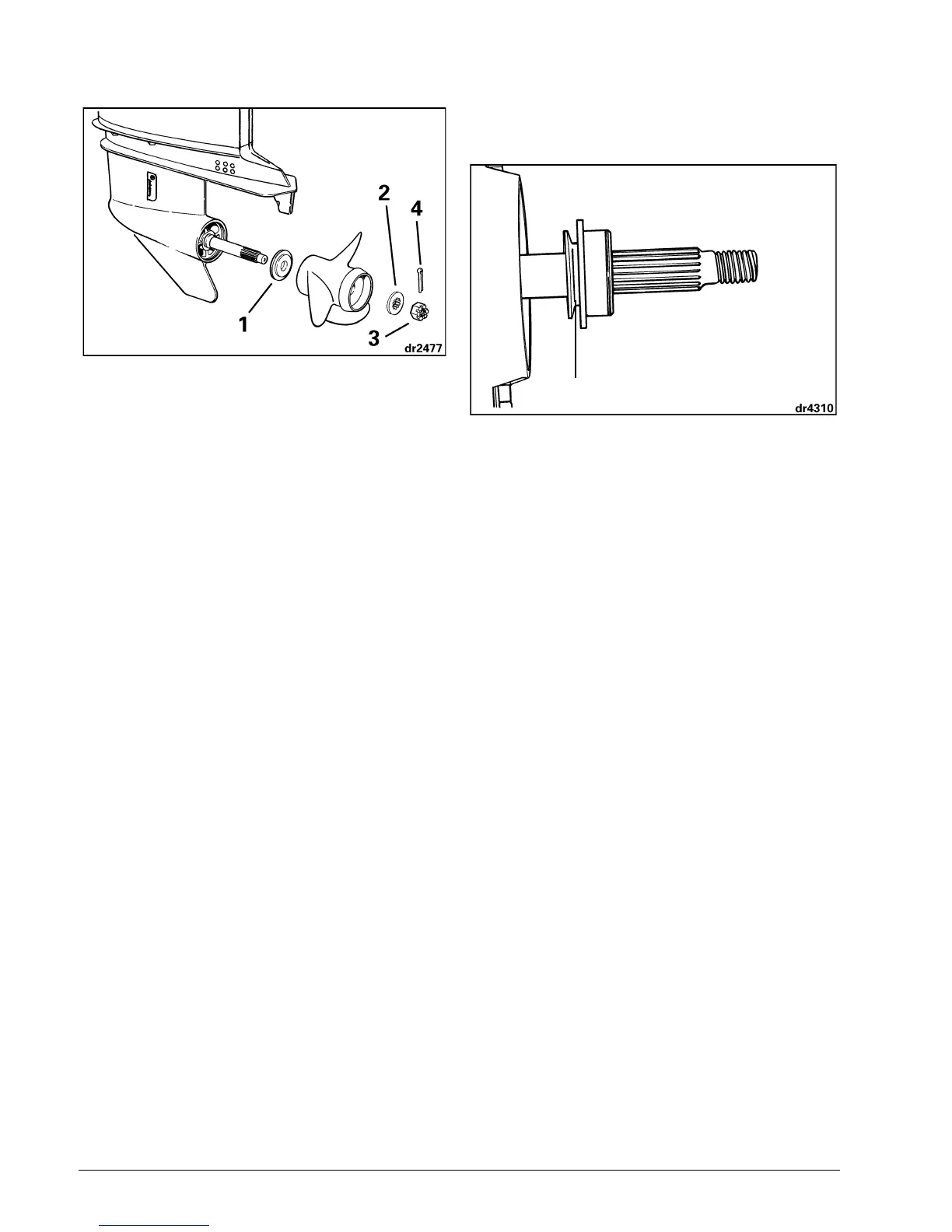

Continue to tighten propeller nut until nut slots and

cotter pin hole are aligned. Install new cotter pin

and bend ends to secure.

1. Thrust washer

2. Spacer

3. Propeller nut

4. Cotter pin

Remove block of wood. Make sure engine is in

NEUTRAL; give propeller a spin. It must turn freely.

Repair

If your propeller hits a solid object, the impact is par-

tially absorbed by the rubber bushing in the hub to

help prevent damage to the engine. A strong impact

can damage the hub and propeller blades. Damage

to blades can cause unusual and excessive vibra-

tion. Damage to the hub can cause excessive en-

gine RPM with little forward movement.

IMPORTANT: Avoid or limit operation using a dam-

aged propeller. Carry a spare propeller.

Keep your propeller in good condition. Use a file to

smooth slight damage to blade edges. See your

DEALER for repair of serious damage.

Fish Line Trap

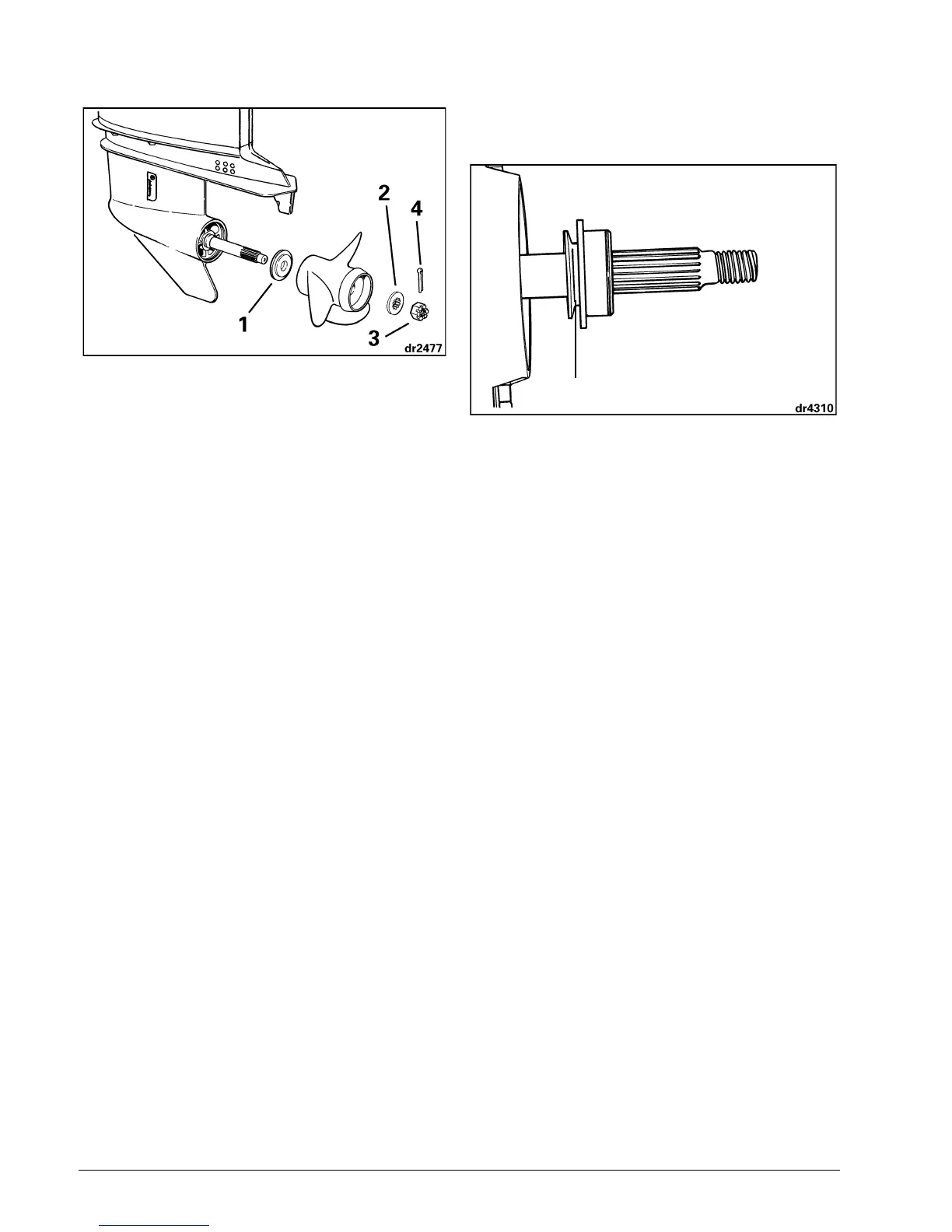

The thrust bushing contains a built-up groove as a

trap for fish line. Every 15 to 20 hours of operation,

or whenever you suspect the presence of fish line,

remove the propeller and check the trap. Remove

any debris.

1. Fish line trap groove

IMPORTANT: Fish line can damage propeller shaft

seals. Damaged seals can allow water to enter the

gearcase, causing internal damage.

1

Loading...

Loading...