Maintenance Guide

2-11

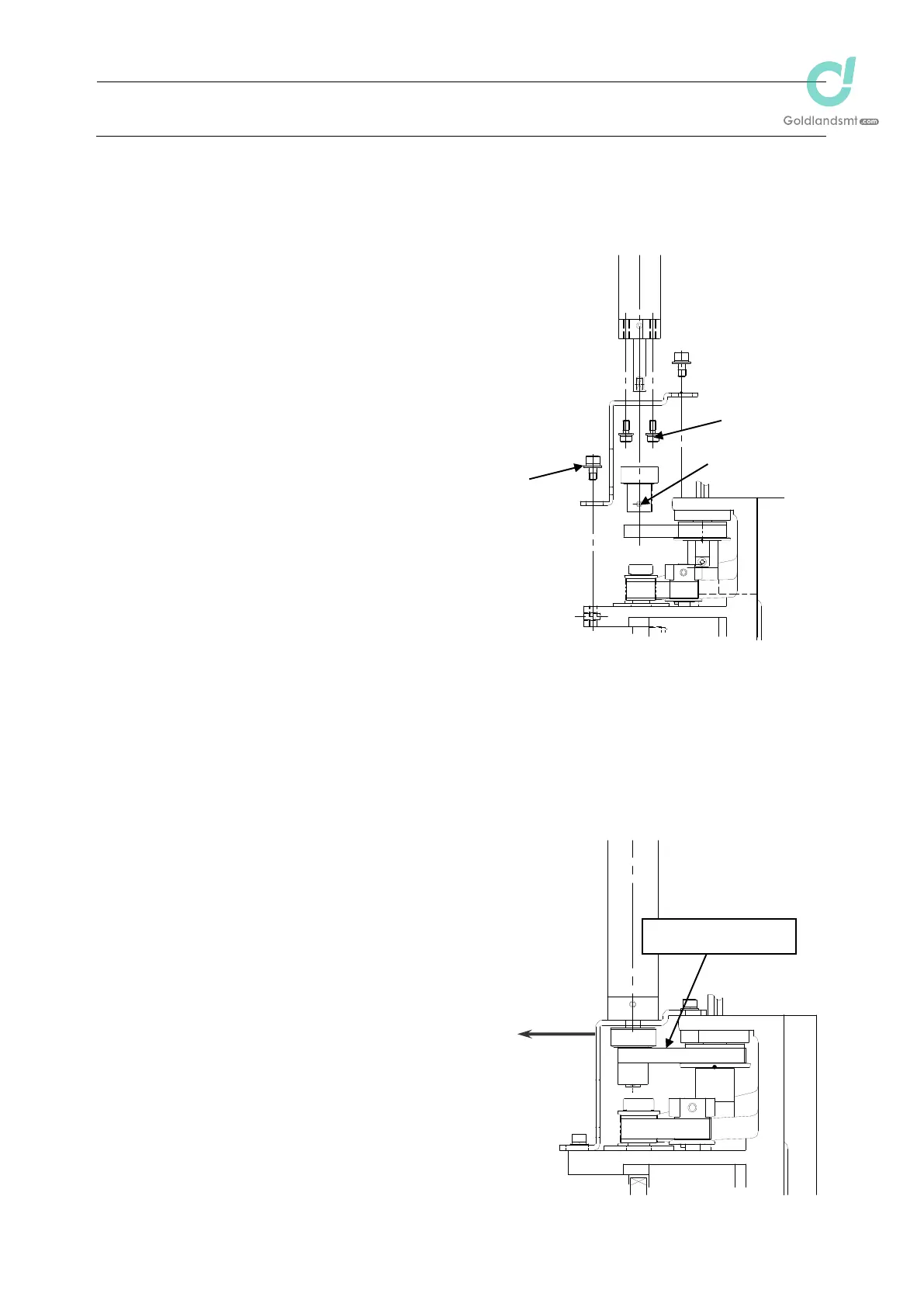

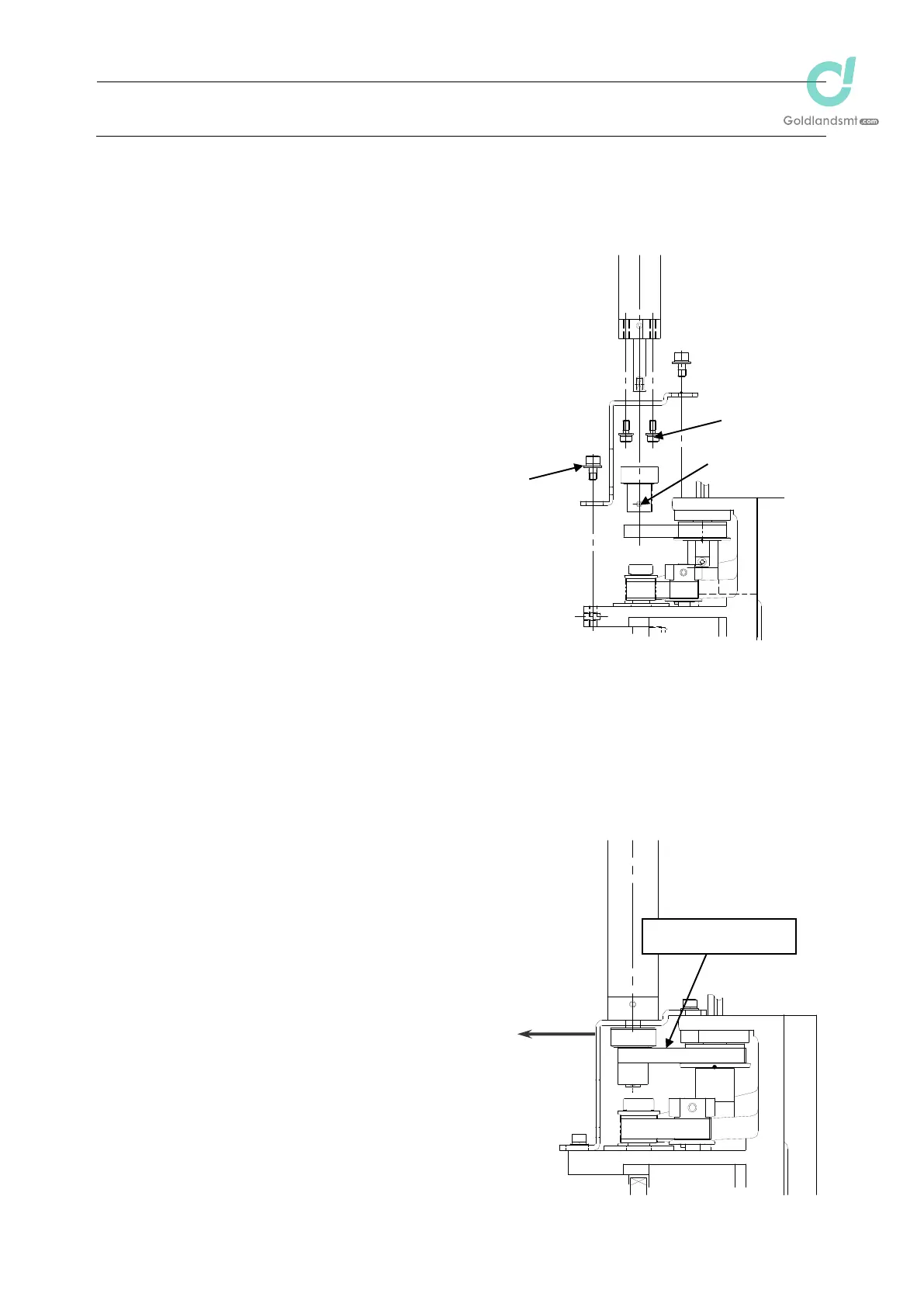

2-2-5. T-Motor (IC Head: KE-2080R)

After the T-motor has been replaced, it is absolutely necessary to re-input the MS parameters

related to the axis home. (For details of input items, see section 2-9.)

(1) Disconnect the motor cables from the servo

amplifier board.

(2) Remove the mounting screws c (3 pcs.) of

the IC T-motor bracket.

(3) Loosen the set screws (2 pcs.) of the IC

T-pulley to detach the pulley.

(4) Remove the mounting screws e (3 pcs.) from

the IC T-motor bracket to detach the motor.

(5) Reassemble the components in the reverse

order of disassembly.

Apply Loctite 242 to the mounting screws

e and tighten them with a tightening

torque of 2.3 N㺃m.

Make the adjustment so that the end face

of the motor shaft is aligned with the end

face of the pulley, and then fix the set screws of the T-pulley.

(6) Follow the steps below to adjust the belt tension.

<Procedure>

c Pull the IC T-motor bracket to adjust the

tension of the timing belt to the status shown

below.

Tension meter set value (For check)

Weight: 1.0g/m Width: 6.0mm

Span: 30.8mm

Proper tension 9.0±1N

When tightening the set screw of the T

pulley, make sure to align the orientation

of the flat part of the T-motor shaft and the

setscrew of the pulley. Tighten the

setscrew with a torque of 0.5 Nm.

Pull

IC Timing belt T

Figure 2-2-5

d

e

c

Loading...

Loading...