– 74 –

3. Portion to which LOCKTITE is applied

LOCKTITE has been applied to the following parts at the time of assembly at the factory.

Avoid disassembling these parts to the most. When an assembly which includes the aforementioned parts

has been forced to be disassembled, be sure to wash the LOCKTITE applied part using a paint thinner or the

like, and reassemble it using LOCKTITE after removing any moisture from the mating faces.

If it is hard to remove a part which has been xed using LOCKTITE, heat it using a torch lamp or the like to

help remove the part.

No. Portion to which LOCKTITE is applied Part No. LOCKTITE No. Remarks

1 Setscrew of coupling SM8050812TP LOCKTITE #243

2 Setscrew of handwheel SM6054502TN LOCKTITE #243 Only LU-2810-6 and 2860-6

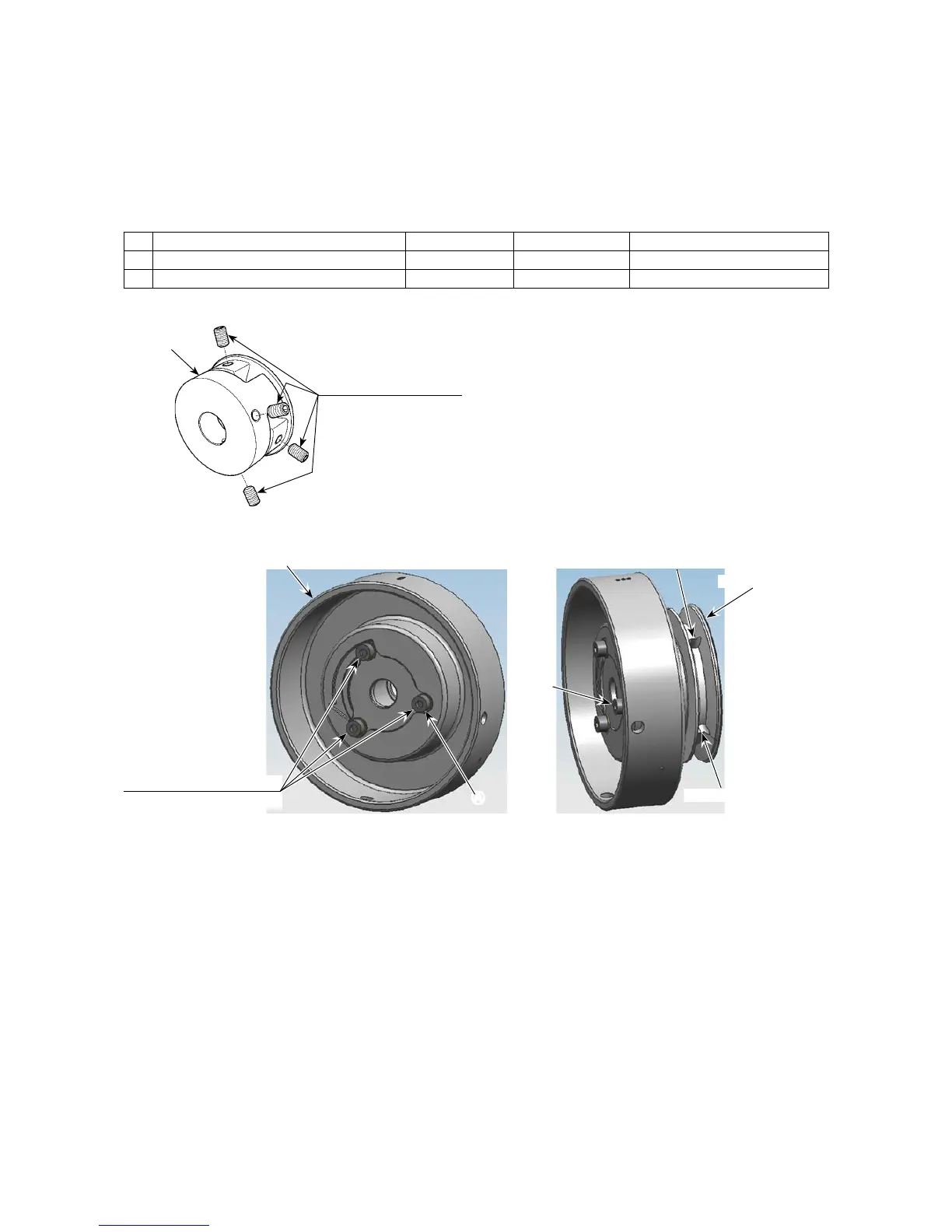

No. 1

No. 2

Setscrews of coupling

LOCKTITE applied

Coupling

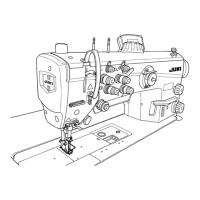

Setscrews of handwheel

LOCKTITE applied

Handwheel

A

Handwheel A

1st setscrew

2nd setscrew

A

(Caution) When an assembly which includes the aforementioned parts has been forced to be disas-

sembled, attach the handwheel so that setscrew

A

(opposite side of the arrow mark indi-

cating the direction of rotation) of the handwheel is located between 1st setscrew and 2nd

setscrew of handwheel A. (Marker dot position of the handwheel will not match.)

Loading...

Loading...