MEB-3200SS

Using conventional machines, it's often quite difficult to reproduce the same

sewing conditions. This machine does it with ease. With this capability,

the MEB-3200 responds immediately to material changes, significantly

reducing the time required for setup changes or adjustments. The machine

also ensures the consistent production of high-quality seams.

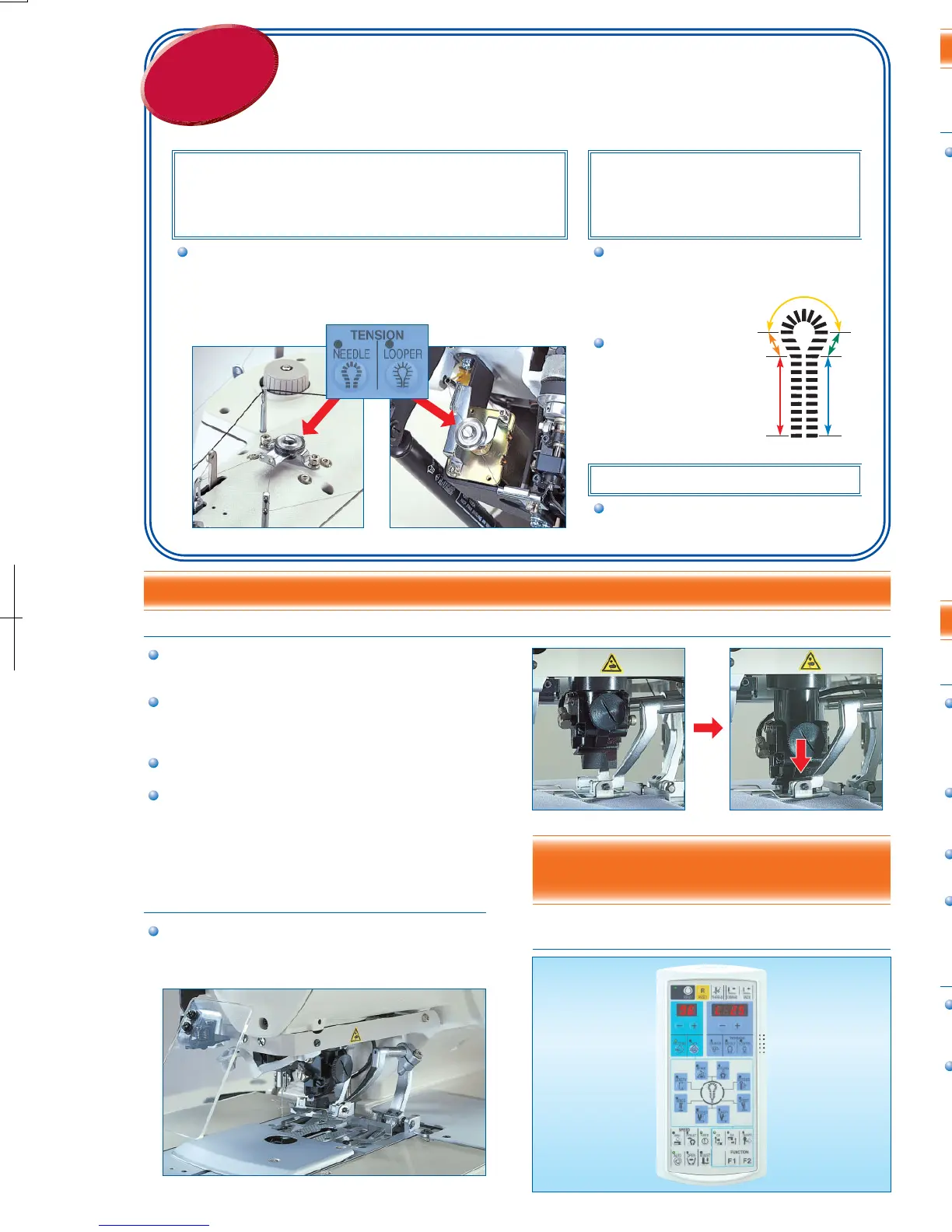

Needle and looper thread tensions can be digitally

established on the operation panel according to sewing

conditions. Data can be registered on a pattern-by-pattern

basis to easily reproduce the same sewing conditions.

The knife is controlled by a stepping motor. This enables easy

adjustment of the knife pressure on the operation panel to suit

the material to be used, thereby preventing irregular cutting.

Data on knife pressure can be registered on pattern-by-pattern

basis to establish the best-suited knife pressure according to

sewing specifications. Adequate knife pressure improves

durability of cloth-cutting knife and knife guard.

Selection between the cut-before knife and cut-after knife can

be made on the operation panel.

The stepping-motor-controlled cloth-cutting knife is free from the

troubles likely to affect air-driven knives, including dull cutting

and the breakage of parts such as the knife-driving arm.

In addition, a large-capacity compressor is no longer required

since the machine uses less compressed air.

The machine promises high-quality seams by

smoothly responding to changes in stitch

formation and allowing the operator to set a

separate thread tension

for the bartacking sections

of buttonholes.

Thread tensions for the

beginning and end of

sewing can also be

separately established.

This helps prevent loose

stitches or slip-off or

raveling of thread at the

beginning of sewing.

For needle thread

For looper thread

Since fewer parts need to be threaded, the

machine can be threaded more quickly and easily

than conventional buttonholing machines.

EXCELLENT CAPABILITIES TO HELP IMPROVE SEAM QUALITY

Thread tensions can be separately

established for various sections of a

buttonhole such as eyelet sections and

parallel sections.

Threading work can be more easily.

Vertically driven cloth cutting knife controlled by a stepping motor.

H

H

Ex

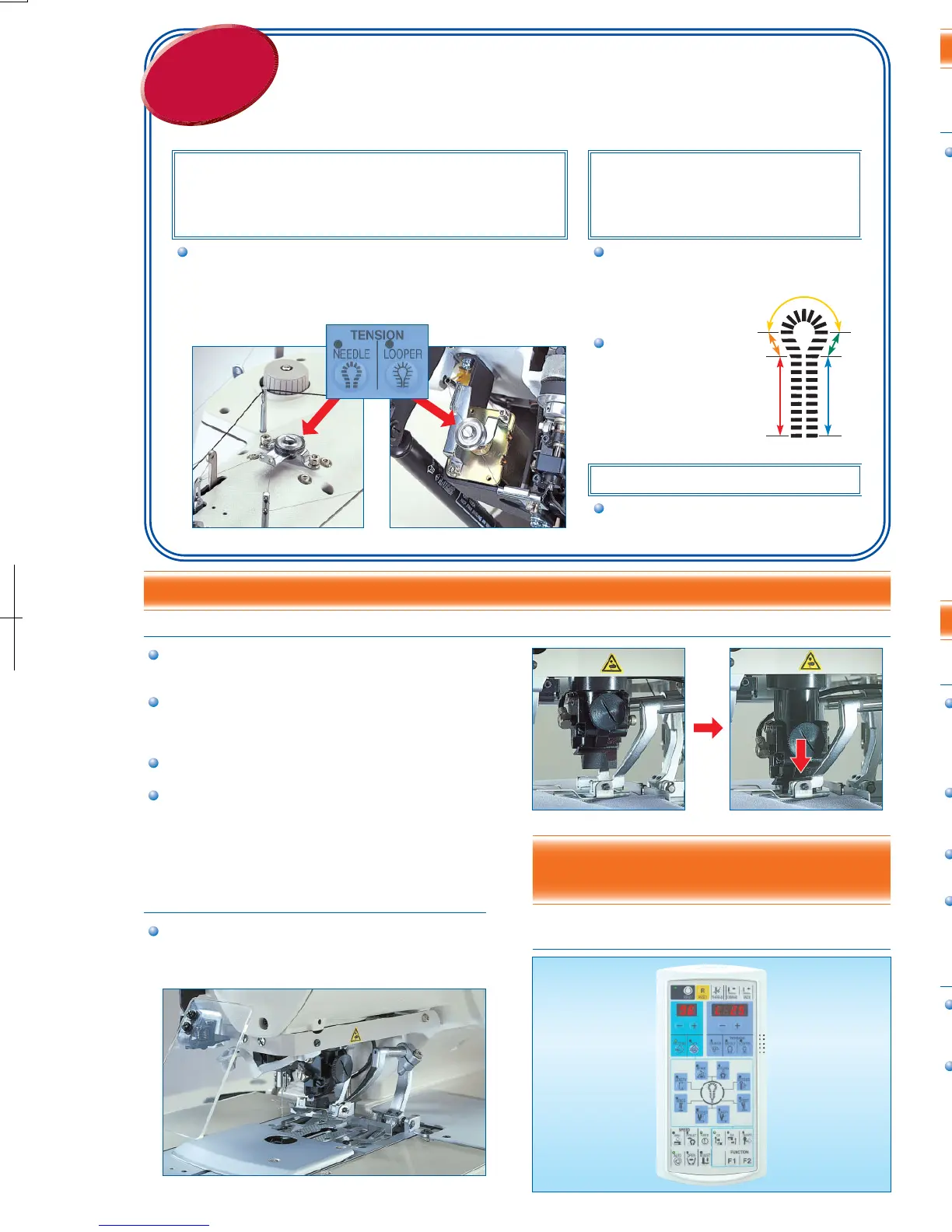

EASY-TO-OPERATE MULTI-

FUNCTIONAL OPERATION PANEL

All pieces of data on sewing specifications can be

established/selected on the operation panel.

Separately driven right and left work clamps.

The right and left work clamps are separately driven by independent air

cylinders. With this mechanism, the work clamps reliably clamp materials

of different thicknesses to prevent the materials from flopping.

THE FIRST

IN THE

WORLD!

THE FIRST

IN THE

WORLD!

Thread tension

Knife comes down

Th

an

on

Ne

lo

AN ACTIVE TENSION MECHANISM (COMPUTER-CONTROLLED

THREAD TENSION MECHANISM) THAT ELECTRONICALLY

CONTROLS THE NEEDLE AND LOOPER THREAD TENSIONS.

AN ACTIVE TENSION MECHANISM (COMPUTER-CONTROLLED

THREAD TENSION MECHANISM) THAT ELECTRONICALLY

CONTROLS THE NEEDLE AND LOOPER THREAD TENSIONS.

AN ACTIVE TENSION MECHANISM (COMPUTER-CONTROLLED

THREAD TENSION MECHANISM) THAT ELECTRONICALLY

CONTROLS THE NEEDLE AND LOOPER THREAD TENSIONS.

Loading...

Loading...