iv

5. Besuretoturnthepoweroffandchecktobesurethatthemachineandmotorcompletelystopbeforere-

movingthebeltcoverandV-beltinordertopreventaccidentcausedbyabruptstartofthemachineormotor.

6. Ifaservomotorisusedwiththemachine,themotordoesnotproducenoisewhilethemachineisatrest.

Besurenottoforgettoturnthepoweroffinordertopreventaccidentcausedbyabruptstartofthemotor.

7. Neverusethemachinewiththecoolingopeningofthemotorpowerboxshieldedinordertopreventre

accidentbyoverheat.

Lubrication

1. BesuretouseJUKIgenuineoilandJUKIgenuinegreasetothepartstobelubricated.

2. Iftheoiladheresonyoureyeorbody,besuretoimmediatelywashitoffinordertopreventinamma-

tionorirritation.

3. Iftheoilisswallowedunintentionally,besuretoimmediatelyconsultamedicaldoctorinordertopre-

ventdiarrheaorvomiting.

Maintenance

1. Inpreventionofaccidentcausedbyunfamiliaritywiththemachine,repairandadjustmenthastobe

carriedoutbyaservicetechnicianwhoisthoroughlyfamiliarwiththemachinewithinthescopedened

intheinstructionmanual.BesuretouseJUKIgenuinepartswhenreplacinganyofthemachineparts.

JUKIassumesnoresponsibilityforanyaccidentcausedbyimproperrepairoradjustmentortheuseof

anypartotherthanJUKIgenuineone.

2. Inpreventionofaccidentcausedbyunfamiliaritywiththemachineorelectrical-shockaccident,besure

toaskanelectricaltechnicianofyourcompanyorJUKIordistributorinyourareaforrepairandmainte-

nance(includingwiring)ofelectricalcomponents.

3. Whencarryingoutrepairormaintenanceofthemachinewhichusesair-drivenpartssuchasanaircyl-

inder,besuretoremovetheairsupplypipetoexpelairremaininginthemachinebeforehand,inorderto

preventaccidentcausedbyabruptstartoftheair-drivenparts.

4. Besuretocheckthatscrewsandnutsarefreefromloosenessaftercompletionofrepair,adjustment

andpartreplacement.

5. Besuretoperiodicallycleanupthemachineduringitsdurationofuse.Besuretoturnthe

poweroff

andverifythatthemachineandmotorstopcompletelybeforecleaningthemachineinordertoprevent

accidentcausedbyabruptstartofthemachineormotor.

6. Besuretoturnthepoweroffandverifythatthemachineandmotorstopcompletelybeforecarryingout

maintenance,inspectionorrepairofthemachine.(Forthemachinewithaclutchmotor,themotorwill

keeprunningforawhilebyinertiaevenafterturningthepoweroff.So,becareful.)

7. Ifthemachinecannotbenormallyoperatedafterrepairoradjustment,immediatelystopoperationand

contactJUKIorthedistributorinyourareaforrepairinordertopreventaccidentthatcanresultinper-

sonalinjuryordeath.

8. Ifthefusehasblown,besuretoturnthepoweroffandeliminatethecauseofblowingofthefuseand

replacetheblownfusewithanewoneinordertopreventaccidentthatcanresultinpersonalinjuryor

death.

9. Besuretoperiodicallycleanuptheairventofthefanandinspecttheareaaroundthewiringinorderto

preventreaccidentofthemotor.

Operatingenvironment

1. Besuretousethemachineundertheenvironmentwhichisnotaffectedbystrongnoisesource(electro-

magneticwaves)suchasahigh-frequencywelderinordertopreventaccidentcausedbymalfunctionof

themachine.

2. Neveroperatethemachineinanyplacewherethevoltageuctuatesbymorethan"ratedvoltage±10%"

inordertopreventaccidentcausedbymalfunctionofthemachine.

3. Besuretoverifythattheair-drivendevicesuchasanaircylinderoperatesatthespeciedairpressure

beforeusingitinordertopreventaccidentcausedbymalfunctionofthemachine.

4. Tousethemachinewithsafety,besuretouseitundertheenvironmentwhichsatisesthefollowing

conditions:

Ambienttemperatureduringoperation 5°Cto35°C

Relativehumidityduringoperation 35%to85%

5. Dewcondensationcanoccurifbringingthemachinesuddenlyfromacoldenvironmenttoawarmone.

So,besuretoturnthepoweronafterhavingwaitedforasufcientperiodoftimeuntilthereisnosign

ofwaterdropletinordertopreventaccidentcausedbybreakageormalfunctionoftheelectricalcompo-

nents.

6. Besuretostopoperationwhenlightningashesforthesakeofsafetyandremovethe

powerplugin

ordertopreventaccidentcausedbybreakageormalfunctionoftheelectricalcomponents.

7. Dependingontheradiowavesignalcondition,themachinemaygeneratenoiseintheTVorradio.Ifthis

occurs,usetheTVorradiowithkeptwellawayfromthemachine.

8. Inordertoensuretheworkenvironment,locallawsandregulationsinthecountrywherethesewing

machineisinstalledshallbefollowed.

Inthecasethenoisecontrolisnecessary,anearprotectororotherprotectivegearshouldbewornac-

cordingtotheapplicablelawsandregulations.

9. Disposalofproductsandpackagesandtreatmentofusedlubricatingoilshouldbecarriedoutproperly

accordingtotherelevantlawsofthecountryinwhichthesewingmachineisused.

v

1. Topreventaccidentscausedbyelectricshockhazards,donotopenthecontrolboxcoverofmotor

ortouchthecomponentsinsidethecontrolbox.

1. Topreventaccidentscausedbyabruptstartofthemachine,depressthestartswitchafter

conrmingthatthereisnointerferenceundertheneedlewhenwindingthread.

2. Topreventaccidentscausedbyabruptstartofthemachine,whenturningONthesetreadyswitch

orthreadingswitch,donotplaceyourngersundertheclothpresserfootsincetheclothpresser

foot automatically comes down.

Donotplaceyourngersneartheclothpresserfootwhilethemachineisinoperation.

3. Donotplaceyourngersneartheneedleentryareaorinsidethethreadtake-upcoverwhilethe

machine is in operation.

4. Beforeremovinganyofthecoversprovidedforyourmachine,thepowerswitchhastobeturned

OFF without fail.

5. Ifyourmachineisprovidedwithsafetydevicessuchascovers,ngerguardsandeyeguards,

neveroperateyourmachinewithanyofthemremoved.Wheneveryoudatachanyofthemfromthe

machine, reinstall it in its original position.

6. Castersandadjustingboltshavetobexedbeforeputtingthemachineintoservice.

7. If it is necessary to suddenly stop the machine while it is in operation, press the temporary stop

switch located on the control panel.

8. Carefullytilt/raisethemachinewithyourbothhands,whennecessary,afterhavingturnedOFF

the

power switch.

9. Thebeltloopsupplyingdevicestartstowork,simultaneouslywiththeturning-ONofthesetready

switch,toallowitsforktomoveatahighspeedwithabeltlooptowardtheareaundertheneedle.

Thismeansthattheforkcouldpierceintoyourhandsorngersifyouplaceyourhandwithin

thedangerousarea.So,itisquitenecessaryforyoutoplaceyourhandatthecorrectoperating

position and not to put it in the dangerous area.

10. Toensuresafety,neveroperatethemachinewiththegroundwireforthepowersupplyremoved.

11. The motor is completely silent when the machine is at rest. So, attention has to be paid not to

forget to turn OFF the power to the machine after the termination of work.

12. Ifthemachineissuddenlymovedfromacoldplacetoawarmplace,dewcondensationmaybe

observed.Inthiscase,turnONthepowertothemachineafteryouhaveconrmedthatthereisno

danger of water drops in the machine.

13. Wheninserting/removingthepowerconnector,thepowerswitchhastobeturnedOFFinprior.

14. Be careful of handling this product so as not to pour water or oil, shock by dropping, and the like

since this product is a precision instrument.

15. ThisisaClassAproduct.Inadomesticenvironmentthisproductmaycauseradiointerference,in

whichcasetheusermayberequiredtomakecorrectiveactions.

16. Be careful to keep your hands away from the operating area of the fork, loop cutter, loop draw-out

device,hookmovingdeviceandthepresserfootsincethosepartscarryouttheirinitialoperation

whenyoupresstheRESETswitchafter

havingturnedthepowerON.

Precautions to be taken so as to use the MOL-254 more safely

Hazardous area

○

×

vi

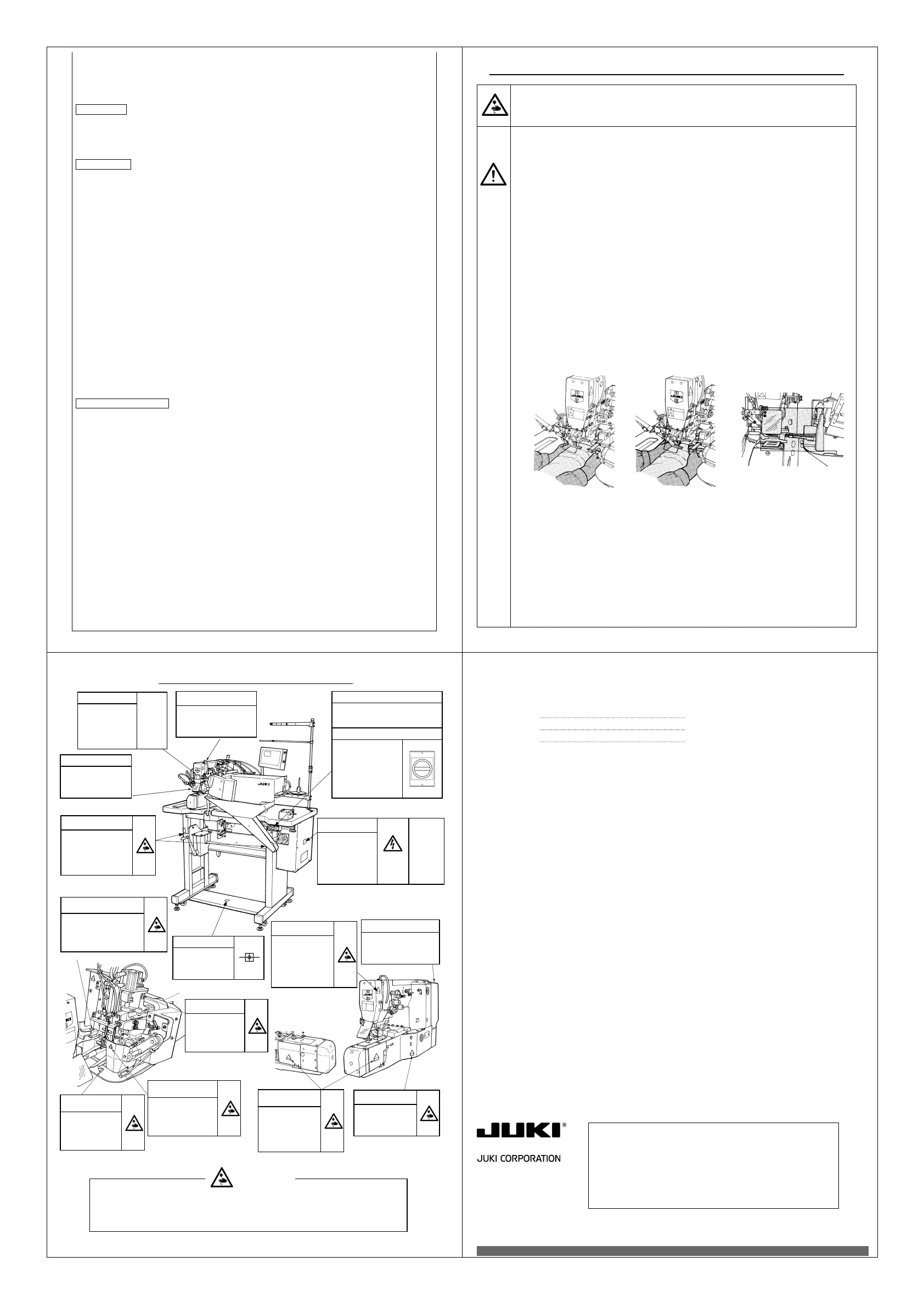

Warning label

against pinching

This label warns

that there is a risk of

pinching of hands in

the table stand when

lifting or lowering the

table.

Safetydevicesandwarninglabels

Eyeprotectioncover

Thisisacoverfor

protecting eyes from

being injured by a

broken needle.

Warning label

(Refer

to the

warning

label on

page i.)

Thelabelgives

the minimum

precautions to be

taken when oper-

ating the sewing

machine.

Electrical-shock

danger label

(EU type)

(Refer to

"Electri-

cal-shock

danger

label"on

page i.)

In order to protect

against electrical

shock, safety

precautions to

betakentoavoid

danger are written

on this label.

Thread take-up

levercover

Thisisacoverforpre-

ventingcontactbetween

the human body and the

threadtake-uplever.

Power switch

This is a switch for disconnecting

the power unit of the sewing ma-

chine from the power supply.

Power switch (EU type)

This switch is used

for disconnecting

the power unit of the

sewing machine from

the power supply.

It is also used as

the emergency stop

switch.

Inaddition,beawarethatthesafetydevicessuchasthe"eyeprotectioncover"and

"ngerguard"aresometimesomittedinthesketches,illustrationsandguresin-

cludedintheInstructionManualfortheexplanation'ssake.Inthepracticaluse,never

removethosesafetydevices.

CAUTION

Motorcover

Thisisacoverforpre-

ventingcontactbetween

the motor and magnet

and the human body.

Warning label

against pinching

This label warns

thatngersor

other parts of

human body can

be pinched in the

thread take-up

lever.

Warning label

against pinching

This label warns

that hands can be

pinched under the

sewing machine.

Warning label

against pinching

This label warns

that there is a risk

of pinching of

hands when the

hook saddle on

frontsidemoves.

Warning label

against pinching

This label warns

that there is a risk

of pinching in the

knife and rotary

drivecylinder.

Warning label

against pinching

This label warns

that there is a risk of

personal injury when

drivingtheloopcut-

ting knife.

Warning label

against pinching

This label warns

that there is a risk

of pinching in the

fork when the fork

moves.

Warning label

against pinching

This label warns that

there is a risk of pinching

of hands in the indicated

partbymovingtheelevat-

ing stand up or down.

Load-center label

This label indi-

cates the center

ofgravityofthe

machine.

vii

EC DECLARATION OF CONFORMITY

We hereby declare that the sewing unit or sewing system described as

complies with the following applicable regulations :

EU Machinery Directive 2006/42/EC

EU EMC Directive 2014/30/EU

EU RoHS Directive 2011/65/EU

Applied harmonized standards, in particular :

EN ISO12100, EN ISO10821, EN IEC 60204-31, EN 50581

Manufacturer :

JUKI CORPORATION

2-11-1, Tsurumaki, Tama-shi, Tokyo, Japan

Model

Description Industrial Sewing Unit

Function automatically make stitches and sew

MOL-254

Please do not hesitate to contact our distributors or agents in your area for further information when necessary.

*

Thedescriptioncoveredinthis"FORTHEUSEOFMACHINE"issubjecttochangefor

improvementofthecommoditywithoutnotice.

Copyright © 2017 JUKI CORPORATION

• All rights reserved throughout the world.

17 · 05 Printed in Japan

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO, 206-8551, JAPAN

PHONE : (81)42-357-2371

FAX : (81)42-357-2274

http://www.juki.com

Loading...

Loading...