Troubleshooting

22 24 690 06 Rev. PKohlerEngines.com

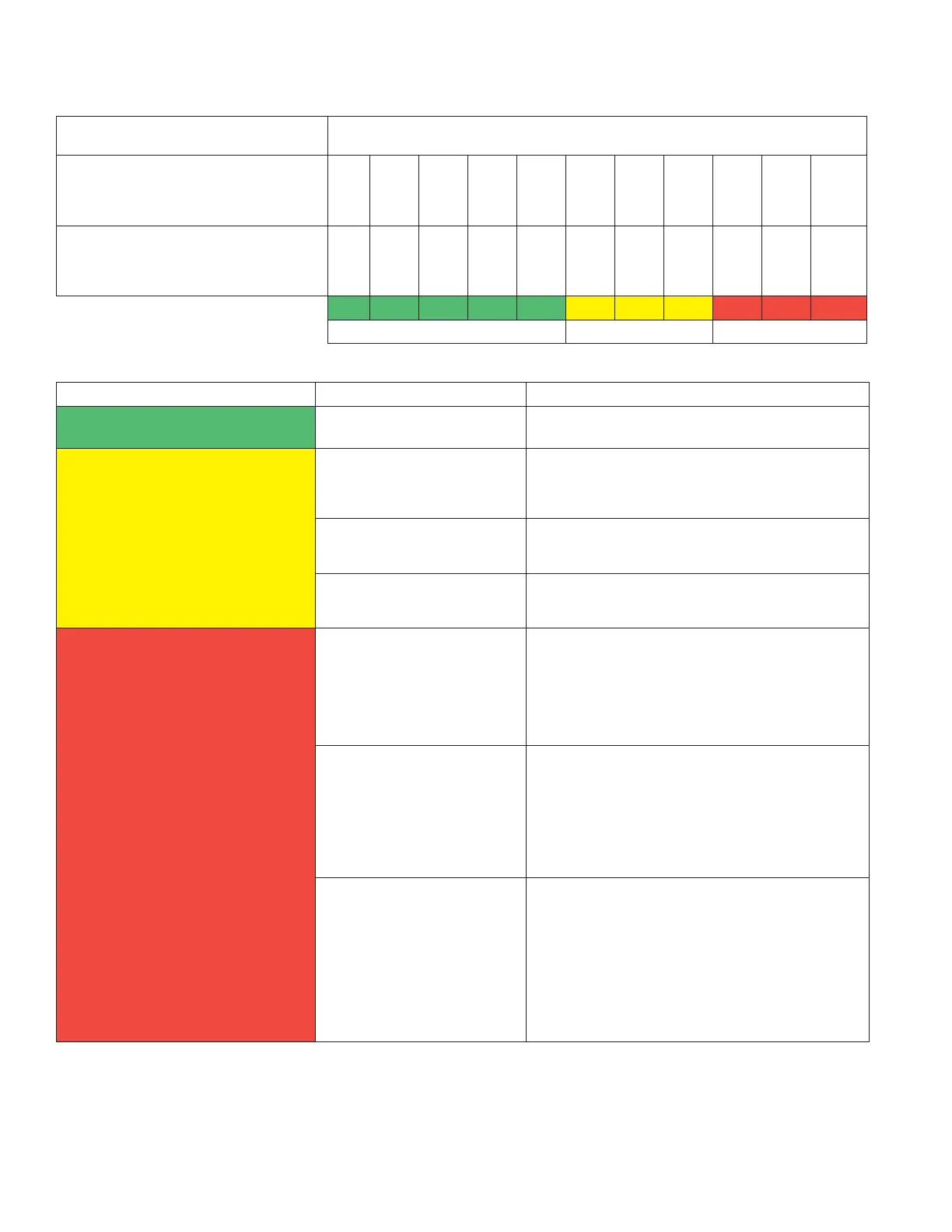

Test Pressure Chart for Dual Gauge Tool

Left Gauge Regulated Pressure

Selection Right Gauge Reading in PSI

80 PSI

Recommended for engines over 200

cc or those exhibiting high leakage at

35 PSI setting.

80 72 64 56 48 40 32 24 16 8 0

35 PSI

Recommended for single cylinder

walk-behind push mower

applications.

35 31.5 28 24.5 21 17.5 14 10.5 7 3.5 0

Percentage of leakage 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Green Zone Yellow Zone Red Zone

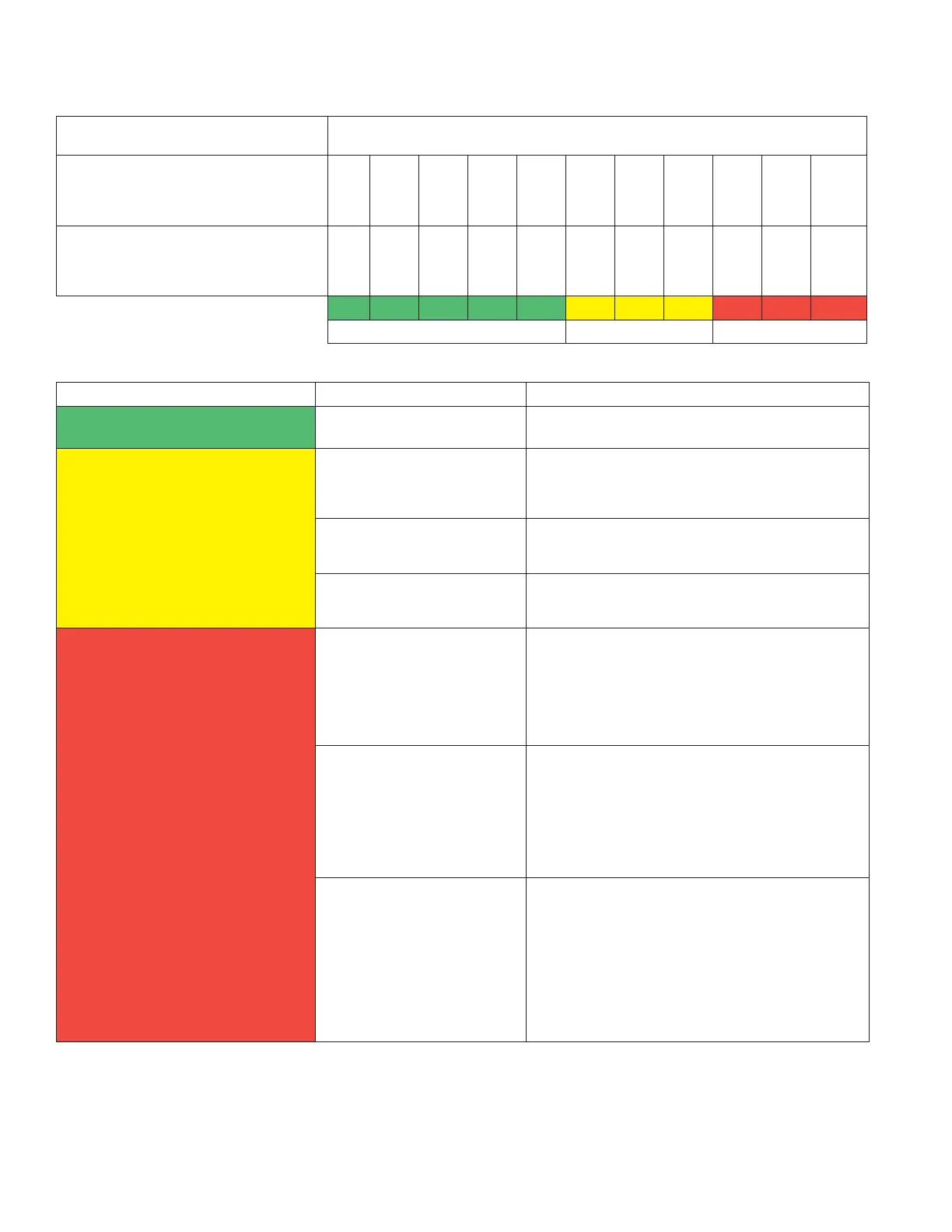

Leakdown Test Results

Test Result Condition Action

Gauge reading in low

(green) zone.

Piston rings and cylinder in

good condition.

No further action required.

Gauge reading in

moderate (yellow)

zone.

Air escaping from crankcase

breather and/or dipstick tube.

Some wear present causing leakage from

combustion chamber to crankcase. Repair not

required at this time if breather system is

functioning normally.

Air escaping from exhaust. Exhaust valve leakage present, possibly due to

carbon deposits. Repair not required. Carbon

cleaning could be performed to reduce leakage.

Air escaping from intake. Intake valve leakage present, possibly due to

carbon deposits. Repair not required. Carbon

cleaning could be performed to reduce leakage.

Gauge reading in

high (red) zone.

Confi rm consecutive leakdown

test has been performed AFTER

engine has been operated under

normal load conditions.

Air escaping from crankcase

breather and/or dipstick tube.

Excess wear present causing leakage from

combustion chamber to crankcase. Breather

system will not function normally and will fail

crankcase vacuum test if this condition is truly

present. Engine disassembly and analysis

required to determine root cause and

correction.

Air escaping from exhaust. Excess exhaust valve leakage present, possibly

due to carbon deposits and/or valve to seat

sealing issues. Carbon cleaning may reduce

leakage. Valve grind and/or component

replacement may be necessary. Excess oil

consumption and/or excess heat is a suspect

cause and must be resolved to prevent

reoccurrence.

Air escaping from intake. Excess intake valve leakage present, possibly

due to carbon deposits and/or valve to seat

sealing issues. Carbon cleaning may reduce

leakage. Valve grind and/or component

replacement may be necessary. Excess oil

consumption through intake valve and/or

excess heat is a suspect cause and must be

resolved to prevent reoccurrence. Inspect

breather system components and intake valve

stem sealing.

Loading...

Loading...