Governor System

4124 690 06 Rev. P KohlerEngines.com

Adjustment

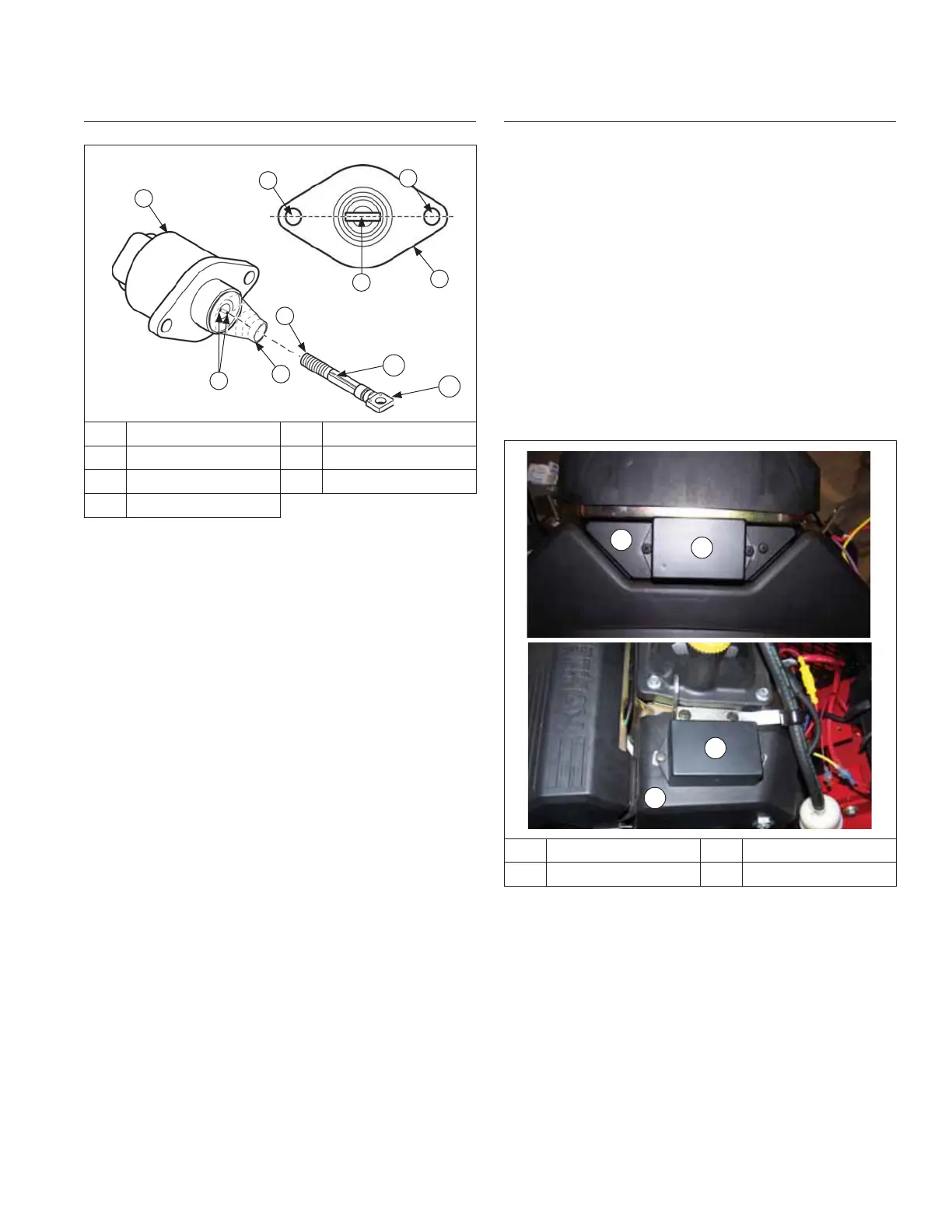

DLA Details

C

C

A

A

B

B

F

D

G

E

A DLA B Mounting Holes

C Clevis D Keyway

E Clevis Shaft F Rubber Boot

G Keys

DLA must be in fully retracted position during assembly.

Full range of throttle plate movement will not be

achieved if DLA is partially extended when assembled.

Loosen DLA mounting plate screws located on top of

actuator plate. With throttle linkage centered in U-Clip or

secured with a retaining clip at end of DLA shaft, press

and hold clevis shaft into actuator, while sliding DLA

bracket assembly back until throttle plate is fully open.

Torque mounting plate screws to 2.5 N·m (22 in. lb.).

If clevis shaft becomes over extended or disconnected

from actuator, replace DLA or reinstall clevis shaft as

follows:

1. Disconnect linkage and remove DLA from bracket.

2. Remove clevis shaft completely out of DLA.

3. Reinstall rubber boot onto DLA if required.

4. Place clevis shaft into actuator. Rotate clevis shaft

clockwise 3 full turns, applying slight pressure, until

you feel clevis shaft keyway make contact with key

in actuator. When clevis is installed properly, fl at of

clevis will be aligned with two DLA mounting holes.

NOTE: Continuing to rotate clevis shaft after it has

made contact with keyway will damage keyway

or actuator.

5. Confi rm that key and keyway are in alignment, by

hand, press clevis shaft into actuator. It will take a

reasonable amount of pressure to do this. If shaft will

not move inward, do not force it. Remove clevis

shaft and repeat previous step.

6. Reinstall DLA into bracket and connect linkage.

Troubleshooting

Engine Starts But Will Not Continue to Run

1. Check linkage connection between DLA and throttle

plate.

2. Verify throttle plate is opened during start procedure.

Engine is unlikely to start if throttle plate is not

opened. Normal opening may be a small amount of

a few degrees.

3. Test OEM control system for output voltage. Refer to

equipment manufacturer’s manual.

4. Check wire harness and connections.

Engine Does Not Run At Expected Speed

1. Check to see that throttle linkage and DLA have full

range of motion having no mechanical interference.

2. Test OEM control system for output voltage. Refer to

equipment manufacturer’s manual.

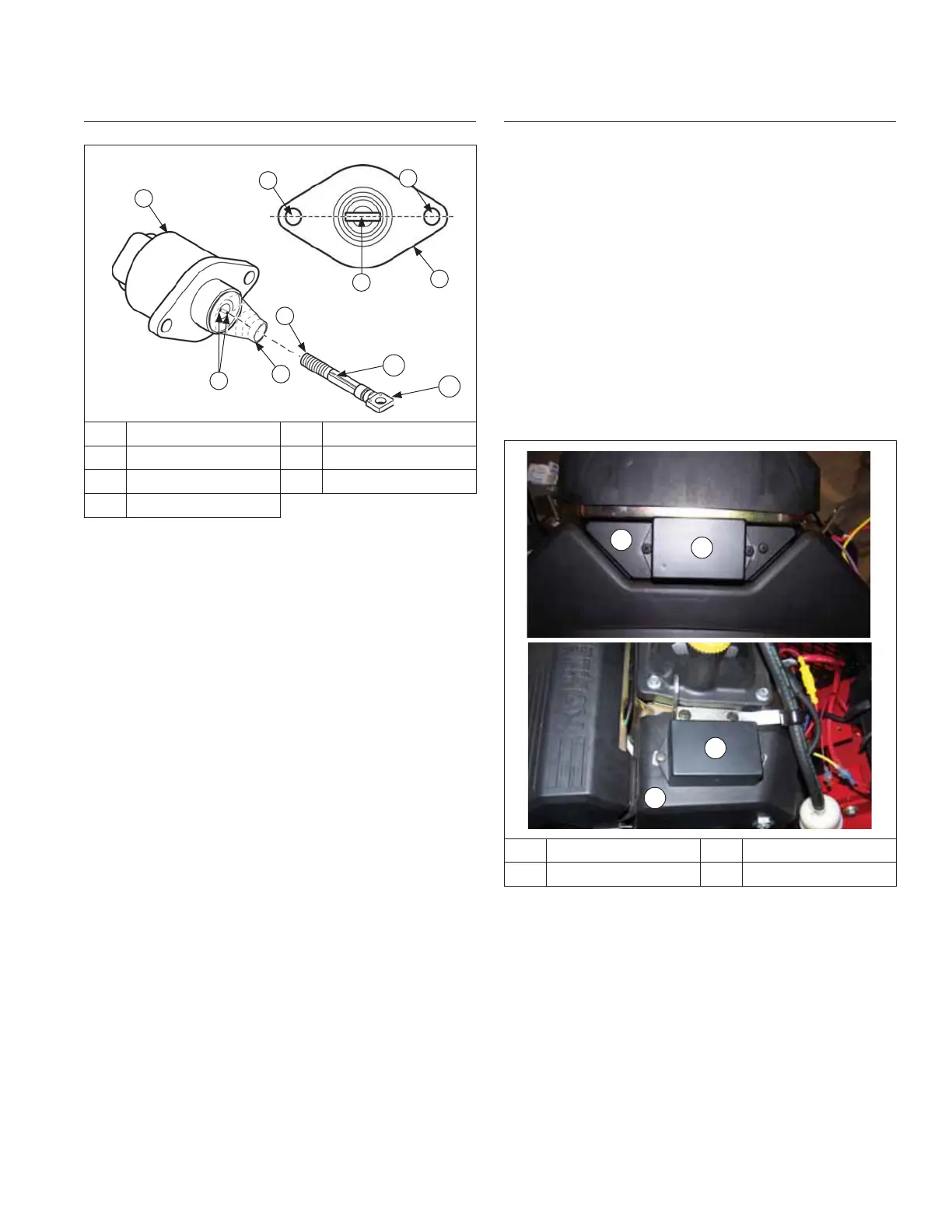

GCU Locations

A

B

C

D

A Panel B GCU

C Blower Housing D GCU

GCU is either secured to a panel on front of engine or to

#1 side of blower housing.

Loading...

Loading...