10.24

Section 10

Reassembly

Prepare the Engine for Operation

The engine is now completely reassembled. Before

starting or operating the engine, be sure the following

have been done.

1. All hardware is tightened securely.

2. The oil drain plug, Oil Sentry™ pressure switch

(if so equipped), and a new oil filter are installed.

3. The crankcase is filled with the correct amount,

weight, and type of oil.

Testing the Engine

It is recommended that the engine be operated on a

test stand or bench prior to installation in the piece of

equipment.

1. Set the engine up on a test stand. Install an oil

pressure gauge. Start the engine and check to be

certain that oil pressure (5 psi or more) is present.

2. Run the engine for 5-10 minutes between idle and

mid-range. Adjust the throle and choke controls

and the high-speed seing as necessary. Make

sure the maximum engine speed does not exceed

3300 RPM. Adjust the carburetor idle fuel needle

and/or idle speed screw as necessary. Refer to

Section 5, Fuel System and Governor.

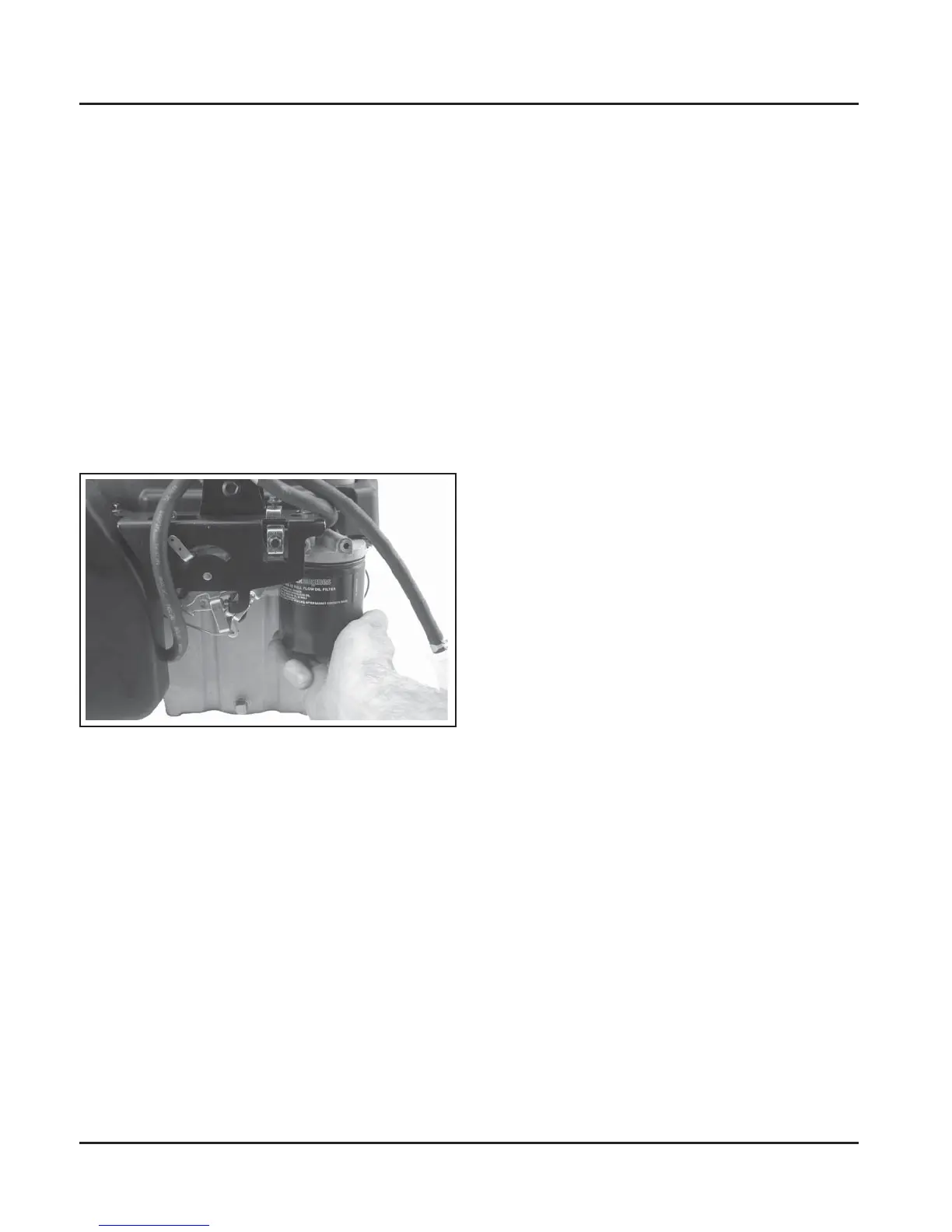

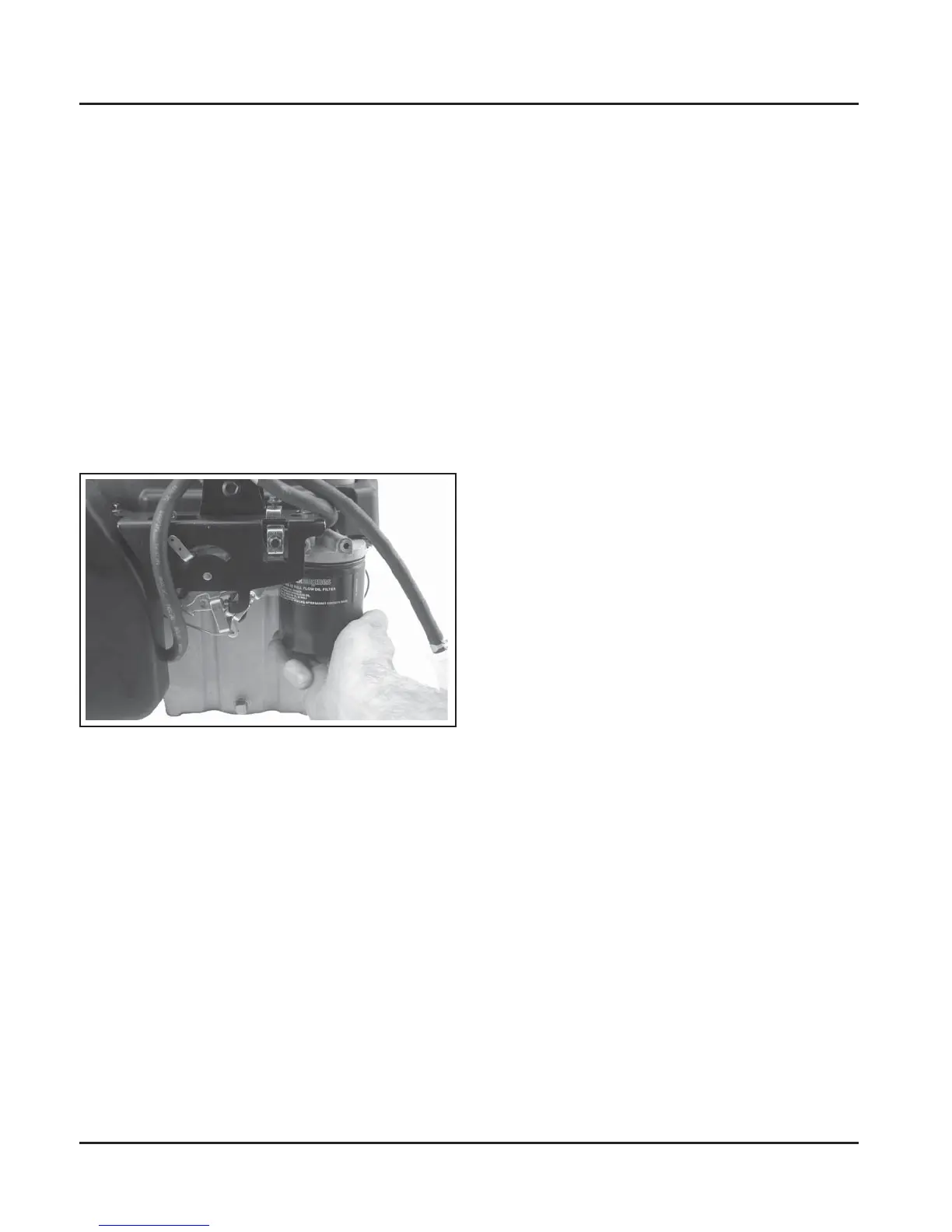

Install Drain Plug, Oil Filter, and Oil

1. Install the oil drain plug and torque to 14 N·m

(125 in. lb.).

2. Place a new replacement filter in a shallow pan

with the open end up. Pour new oil of the proper

type, in through the threaded center hole. Stop

pouring when the oil reaches the boom of the

threads. Allow a minute or two for the oil to be

absorbed by the filter material.

3. Apply a thin film of clean oil to the rubber gasket

on the new filter. Install the new oil filter to the

filter adapter or oil cooler. Refer to instructions

on the oil filter for proper installation. See Figure

10-84. Fill the crankcase with new oil of the

proper type, to the “F” mark on the dipstick.

Figure 10-84.Installing Oil Filter.

Loading...

Loading...