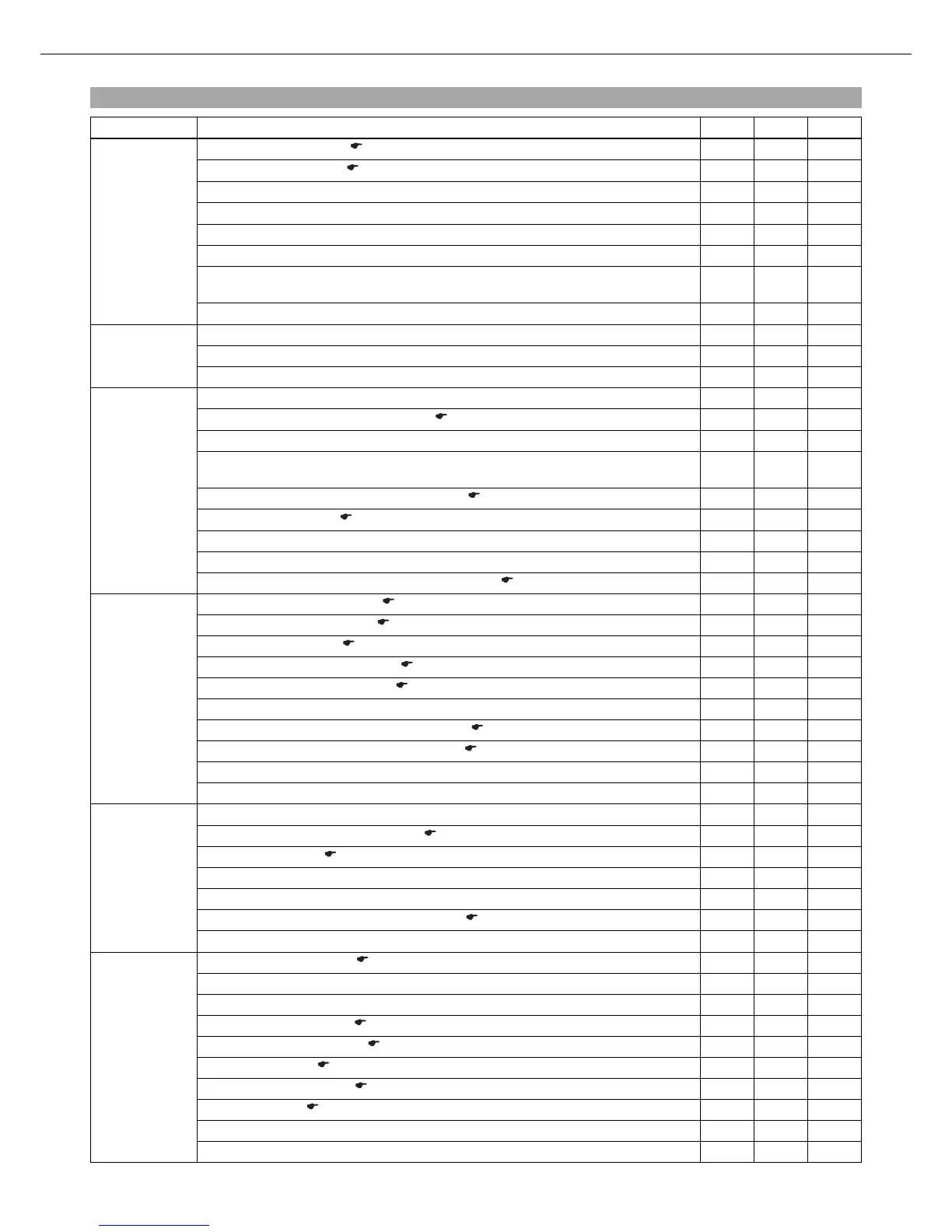

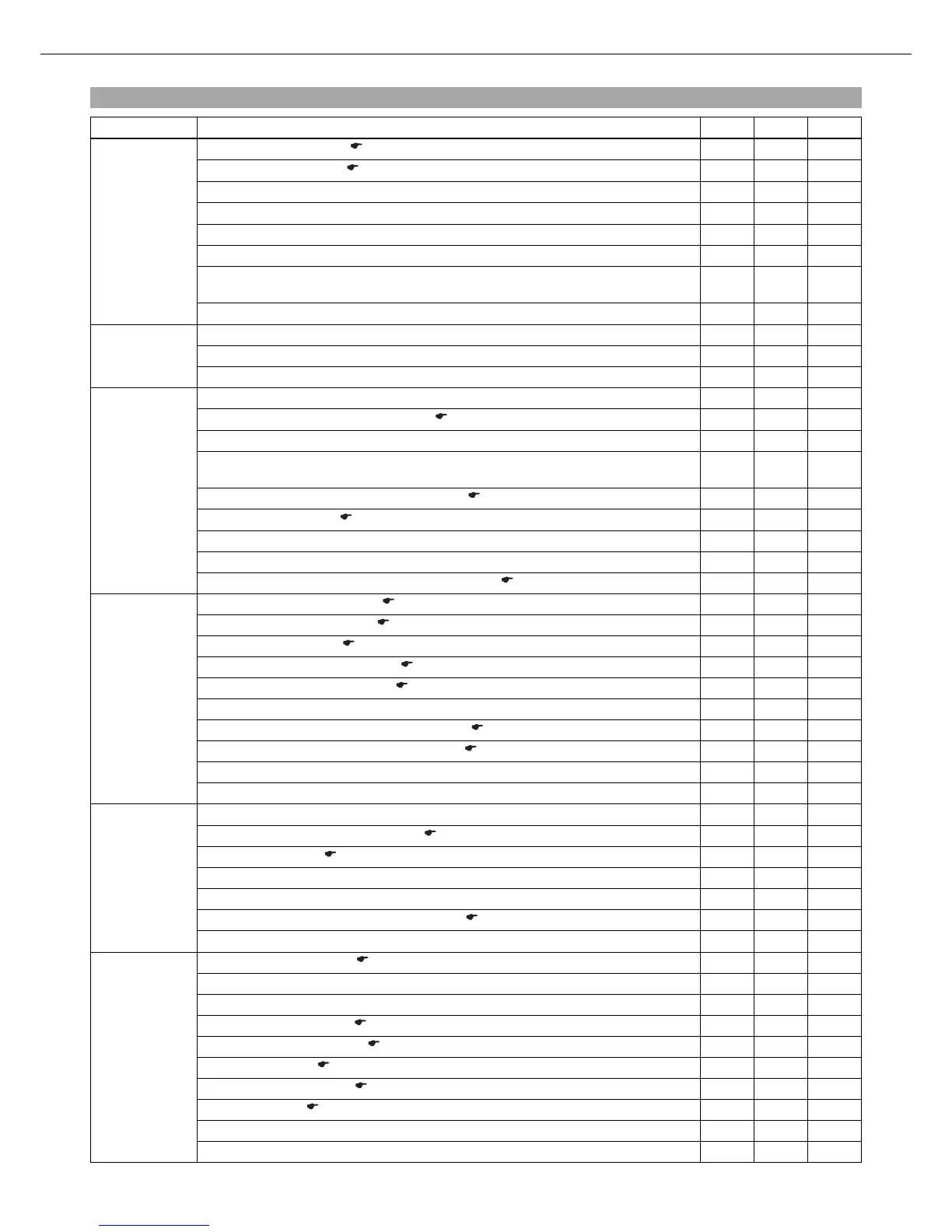

SERVICE SCHEDULE 35

10.1Important maintenance work to be carried out by an authorized KTM workshop

S10N S20A S40A

Engine Check the gear oil level. ( p. 88) • •

Change the gear oil. x ( p. 88)

• •

Check spark plug and replace if required. x

• • •

Clean the spark plug connectors and check for tightness. x

• •

Check that the screws in the shift lever and the kickstarter are tight. • • •

Check the engine mounting screws for tightness. • • •

Clean the bearing bush in the starter drive, check that it is seated firmly and grease

it. x (250 EXC AUS/XC‑W/XC, all 300 models)

•

Check the starter drive for play. x (250 EXC AUS/XC‑W/XC, all 300 models)

•

Carburetor Check intake flange and carburetor connection boot for cracks and leakage. • •

Check the idle. • •

Check the vent hoses for damage and routing without sharp bends. • •

Attachments Check the cooling system for leakage. • •

Check the antifreeze and coolant level. ( p. 77) • •

Check the exhaust system for leakage and looseness. • •

Check the throttle cables for damage, smooth operation and routing without sharp

bends.

• • •

Check the fluid level of the hydraulic clutch. ( p. 83) • • •

Clean the air filter. x ( p. 82)

• • •

Check the cables for damage and routing without sharp bends. • •

Check that the electrical equipment is functioning properly. • • •

Check the headlight setting. (EXC, EXC SIX DAYS) ( p. 74) • • •

Brakes Check the front brake linings. ( p. 60) • •

Check the rear brake linings. ( p. 64) • •

Check the brake discs. ( p. 58) • •

Check the front brake fluid level. ( p. 59) • • •

Check the rear brake fluid level. ( p. 63) • • •

Check the brake lines for damage and leakage. • •

Check the free travel of the hand brake lever. ( p. 58) • • •

Check the free travel of the foot brake lever. ( p. 62) • • •

Check that the brake system is functioning properly. • • •

Check the screws and guide bolts of the brake system for tightness. • • •

Chassis

Check the shock absorber and fork for leakage and functioning. x

• • •

Clean the dust boots of the fork legs. ( p. 47) • • •

Bleed the fork legs. ( p. 47) • • •

Check the frame and swingarm for damage. • •

Check the swingarm bearing. • •

Check the play of the steering head bearing. ( p. 48) • •

Check all screws to see if they are tight. • •

Wheels Check the spoke tension. ( p. 70) • • •

Check the wheel hubs for damage. • • •

Check the rim run-out. • • •

Check the tire condition. ( p. 69) • • •

Check the tire air pressure. ( p. 70) • • •

Check chain wear. ( p. 55) • • •

Check the chain tension. ( p. 55) • • •

Clean the chain. ( p. 54) • • •

Check the wheel bearing for play. • •

Clean and grease the adjusting screws of the chain adjuster. • • •

S10N: once after 10 operating hours

Loading...

Loading...