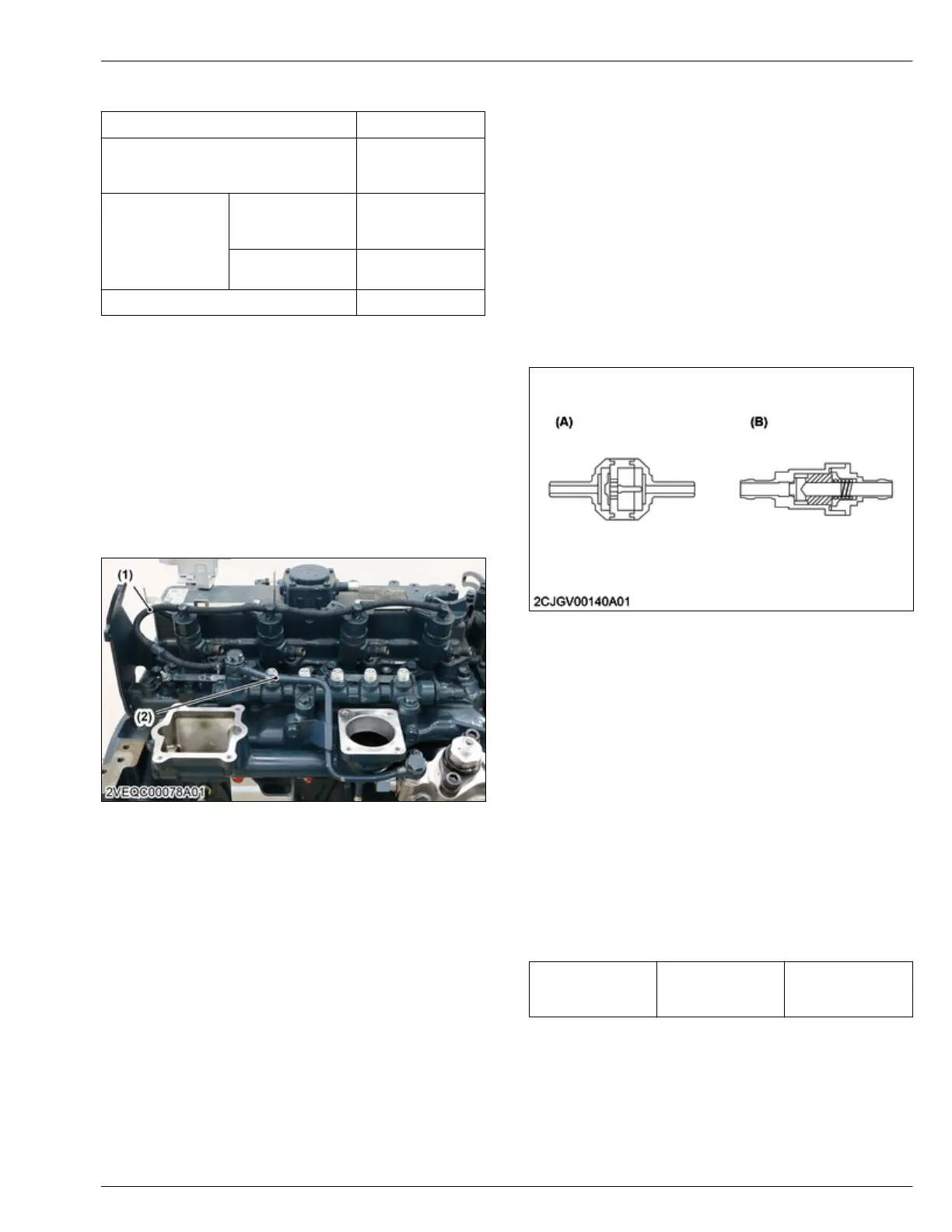

3.13.4 Specification of injector

Operating voltage 110 V

Operating pressure range

30.0 to 160 MPa

306 to 1630 kgf/cm

2

4360 to 23200 psi

Number of injection

holes

D1803-CR-E4, TE4,

V2403-CR-E4, TE4,

TE4BG

7

D1803-CR-TIE4,

V2403-CR-TIE4

8

QR correction points 4

3.14 Overflow pipe

3.14.1 Outline of overflow pipe

The overflow pipe is a path for returning excess fuel

after injection to the tank.

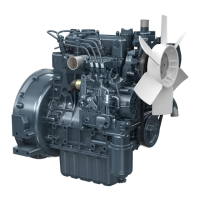

3.14.2 Structure of overflow pipe

The overflow pipe is made up of two pipes, the return

from

the

injectors and the return from the supply pump

and rail.

(1) Overflow hose (2) Overflow pipe

3.14.3 Function of overflow pipe

The overflow

pipe is a path for returning excess fuel

after injection to the tank.

3.15 Check valve

3.15.1 Outline of check valve

The check valve prevents reverse flow of fuel inside the

fuel piping.

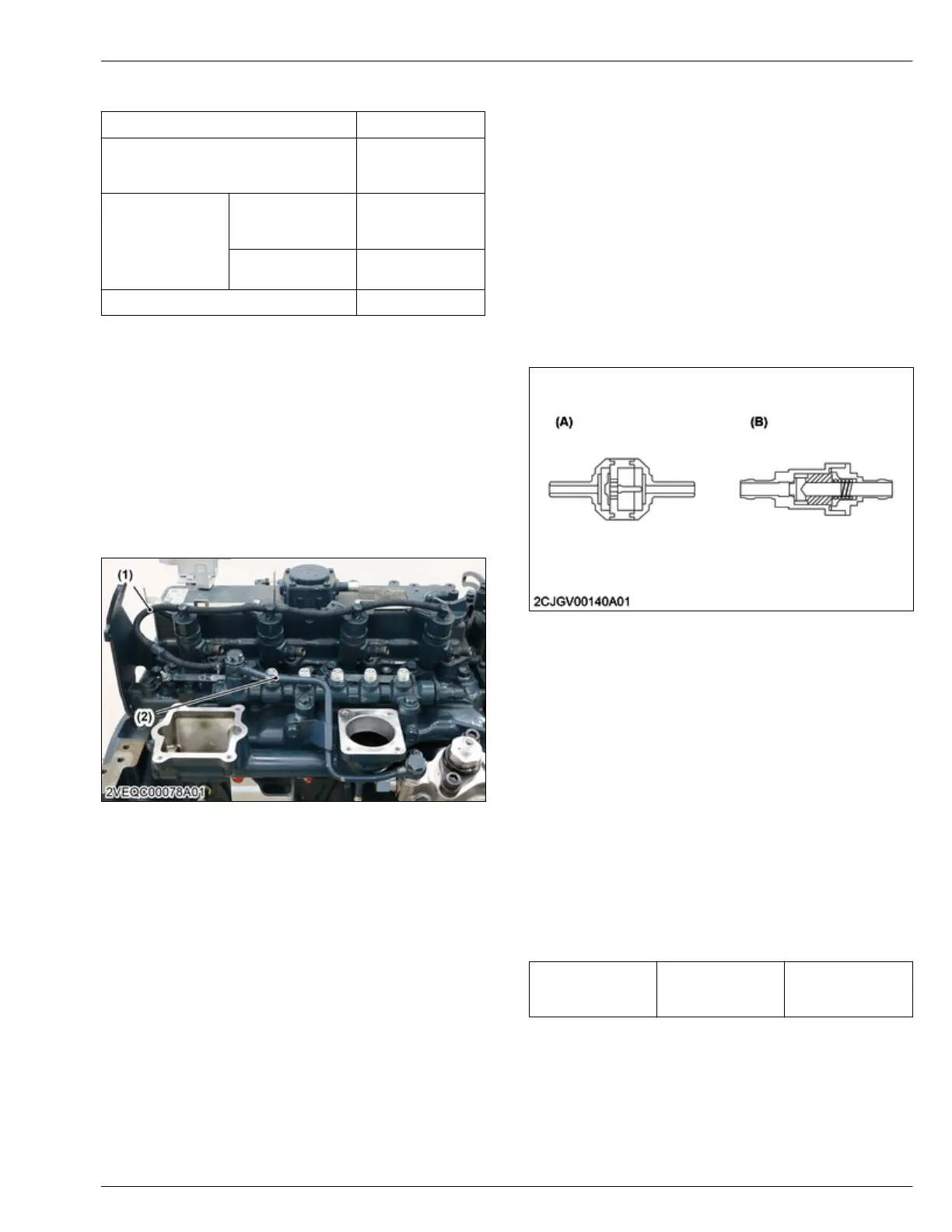

3.15.2 Structure of check valve

There are two types of check valves, with or without a

regulator.

(A) No regulator (B) Regulator included

3.15.3 Function of check valve

The check valve prevents reverse flow of fuel inside the

fuel piping.

The check valve is being used as a no-return valve.

A

check

valve without a regulator is used in the return

path from the fuel filter.

This path is used as a return path for excess fuel and

for air bleeding.

A check valve with a regulator is used in the return path

from the overflow pipe.

This is to retain back pressure inside the return path

from the overflow pipe.

3.15.4 Specification of check valve

Valve opening pres-

sure

Regulator included

11 kPa

0.11 kgf/cm

2

1.6 psi

3.16 Fuel cooler

3.16.1 Outline of fuel cooler

The fuel cooler cools fuel returning from the engine.

Cooling

fuel

returning to the fuel tank prevents

temperature increase of the fuel in the fuel tank.

MECHANISM

3. Fuel system 4. ENGINE

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...