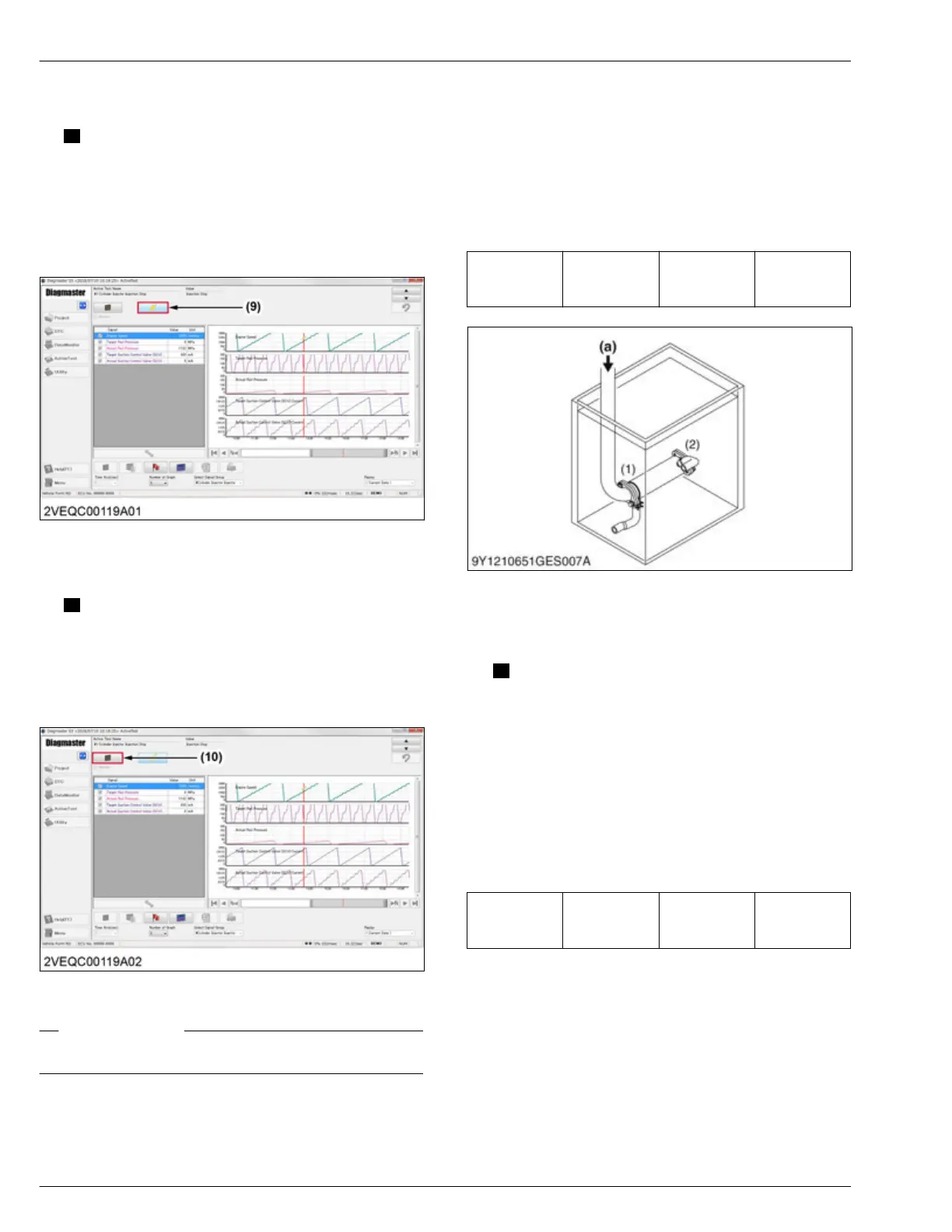

7. Click

the [Send

Specified Active Test Value]

button (9).

NOTE

• Confirm that

the each injectors are injecting

normally.

• If it is injecting normally, the engine

vibration and noise will increase and engine

speed will fluctuate when the injector is

stopped.

(9) Send Specified Active Test

Value button

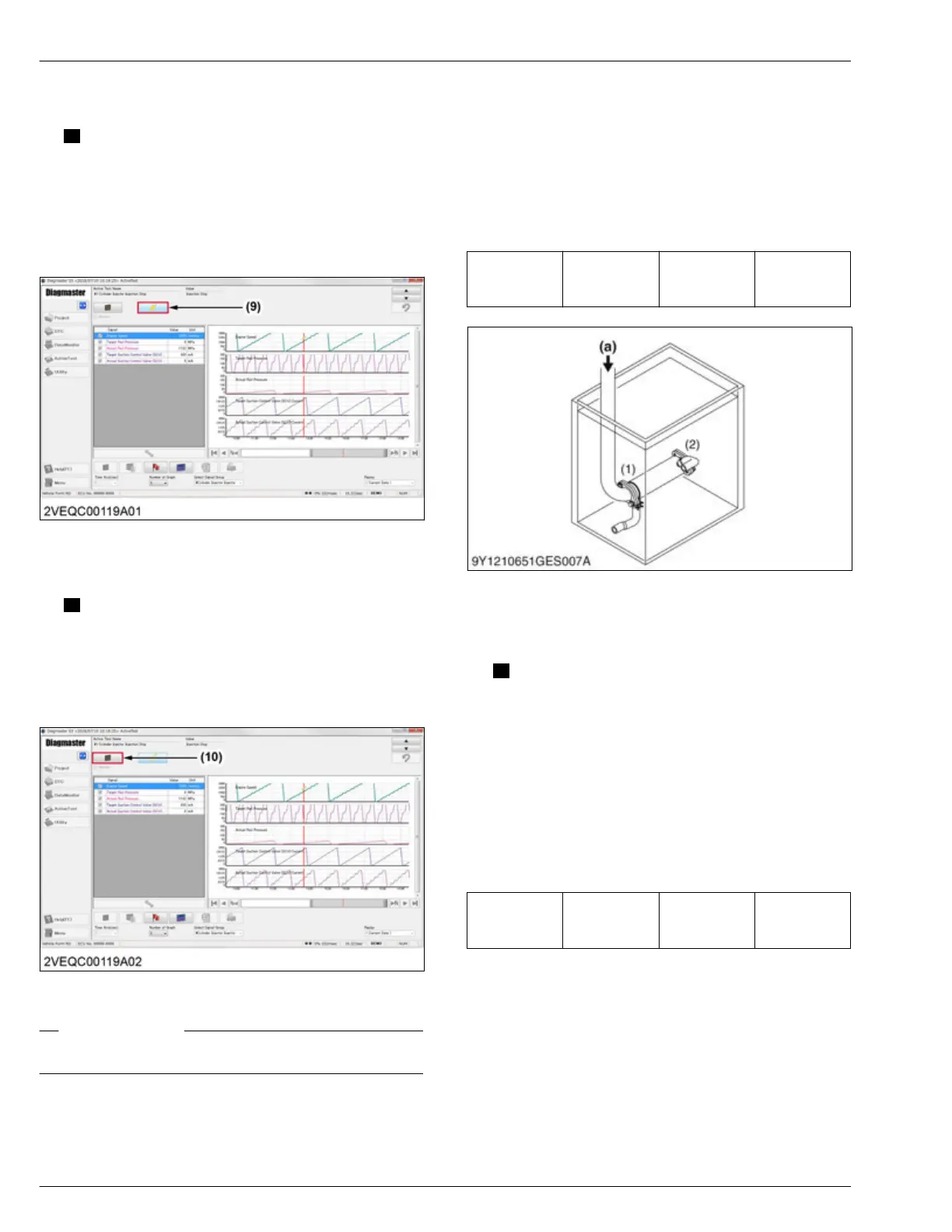

8.

Click the [Finish Active T

est]

button (10).

NOTE

• If it

is determined that there is a failure,

check for a plug in the injection pipe.

• If the injector pipe is normal, this may be an

injector failure so replace the injector using

the procedure for replacing injectors.

(10) Finish Active Test button

RELATED PAGE

7.56 Replacing injector on page 4-191

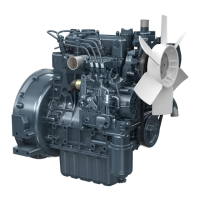

8.2 Checking EGR cooler

Exhaust gas passage

1. Block the EGR cooler exhaust gas outlet (2).

2.

Attach an air hose to the EGR cooler exhaust gas

inlet (1) and then submerge it in a water tank.

3. Check that the coolant passage is full of water.

4. Apply the specified amount of air pressure (a) to the

air hose side.

EGR cooler

leakage test

pressure

Service speci-

fication

Exhaust gas

passage

290 kPa

3.0 kgf/cm

2

43 psi

(1) Exhaust gas inlet

(2) Exhaust gas outlet

(a)

Air pressure

5. Check that there are no air leaks in any of the EGR

cooler parts.

NOTE

• If there are air leaks, replace the EGR cooler.

6. Install the removed parts.

Coolant passage

1. Block the

EGR cooler exhaust gas inlet (1), EGR

cooler exhaust gas outlet (2), and the coolant outlet

(3).

2. Attach an air hose to the EGR cooler coolant inlet

(4), and then submerge it in a water tank.

3. Apply the specified amount of air pressure (a) to the

air hose side.

EGR cooler

leakage test

pressure

Service speci-

fication

Coolant pas-

sage

250 kPa

2.5 kgf/cm

2

36 psi

3. MAINTENANCE

CHECK AND MAINTENANCE

8.Check points of every 1500 hours

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...