Paragraph 8 Cont.

KUBOTA

Fig. 19—Rolling torque of bevel ptnton shaft

with differential assembly Instatted shouid be

within range of 1.96-2.94 N-m (17-26 tn.-tbs.).

Refer to text

Side gear thrust washers (20-Fig. 16)

are available in three different

thicknesses to adjust backlash to desired

value. Tighten ring gear mounting cap

screws to a torque of 61-68 N-m (45-50

ft.-lbs.).

Assemble bevel pinion shaft using new

bearings and oil seal. Tighten adjusting

nut finger tight, then reinstall pinion

shaft and case into differential housing.

Use a torque wrench to measure torque

required to turn pinion shaft as shown in

Fig. 18. Tighten adjusting nut (1-Fig.

16) to obtain recommended rolling tor-

que of

1.27-1.67

N-m (11-15 in.-lbs.).

Stake adjusting nut after bearing ad-

justment is completed.

Install differential assembly and ring

gear into differential case and reinstall

axle housing.Measure torque required to

Fig. 20—Use a diai indicator to check backlash

between ring gear and pinion. Recommended

backlash Is 0.15 mm

(0.006-0.010

inch).

Fig. 21—Exploded view of one piece drive shaft

assembly used on some modets.

1.

Front tube

2.

"0" ring 5. Drive shaft

3.

Snap ring 6. Rear cover

4.

Coupling 7. Gasket

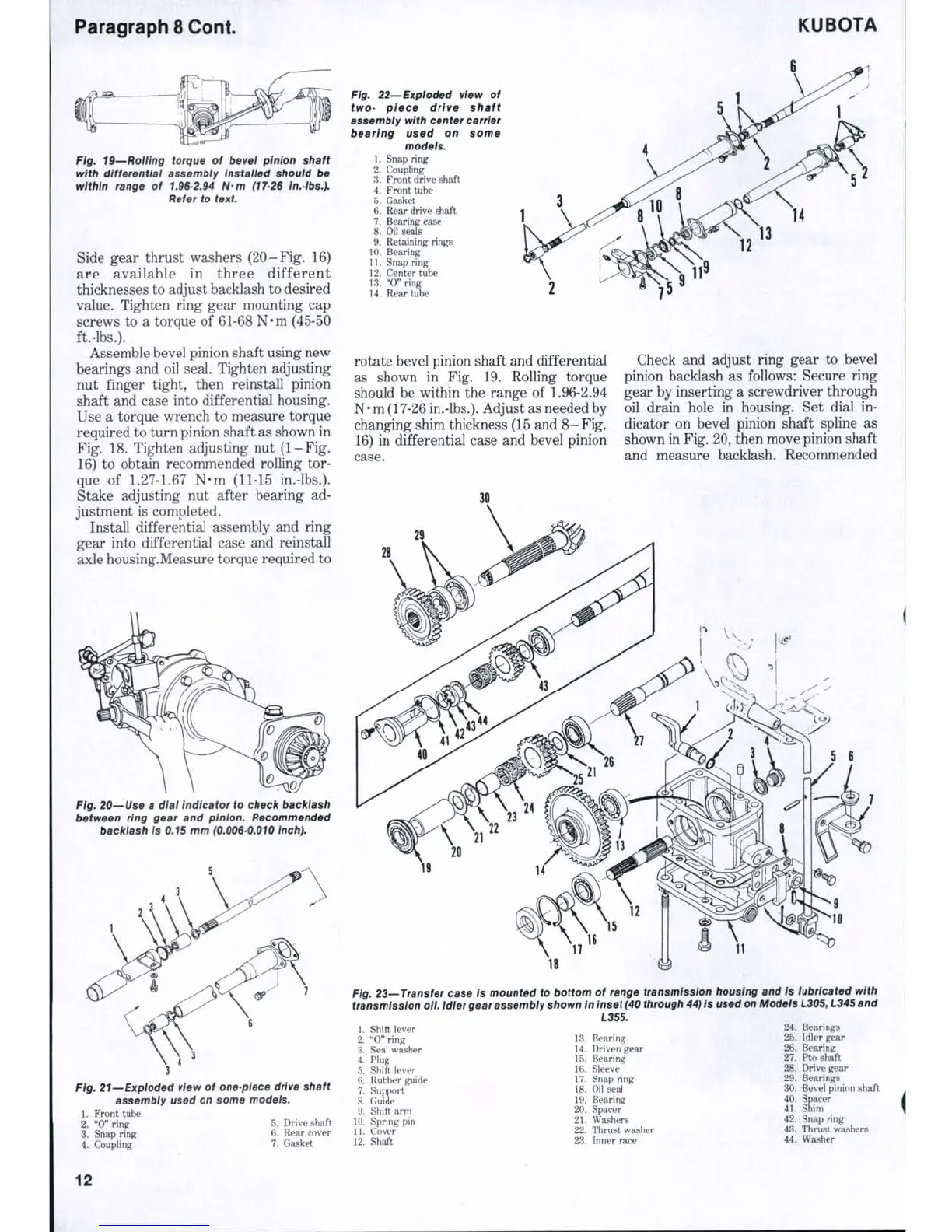

Ftg. 22—Exploded view of

two-

piece drive shaft

assembly

with center carrier

bearing used on some

models.

1.

Snap ring

2.

Coupling

3.

Front drive shaft

4.

Front tube

5.

Gasket

6. Rear drive shaft

7.

Bearing case

8. Oil seals

9. Retaining rings

10.

Bearing

11.

Snap ring

12.

Center tube

13.

"0" ring

14.

Rear tube

rotate bevel pinion shaft and differential

as shown in Fig. 19. Rolling torque

should be within the range of

1.96-2.94

N-m (17-26

in.-lbs.).

Adjust as needed by

changing shim thickness (15 and 8-Fig.

16) in differential case and bevel pinion

case.

Check and adjust ring gear to bevel

pinion backlash as follows: Secure ring

gear by inserting a screwdriver through

oil drain hole in housing. Set dial in-

dicator on bevel pinion shaft spline as

shown in Fig. 20, then move pinion shaft

and measure backlash. Recommended

II

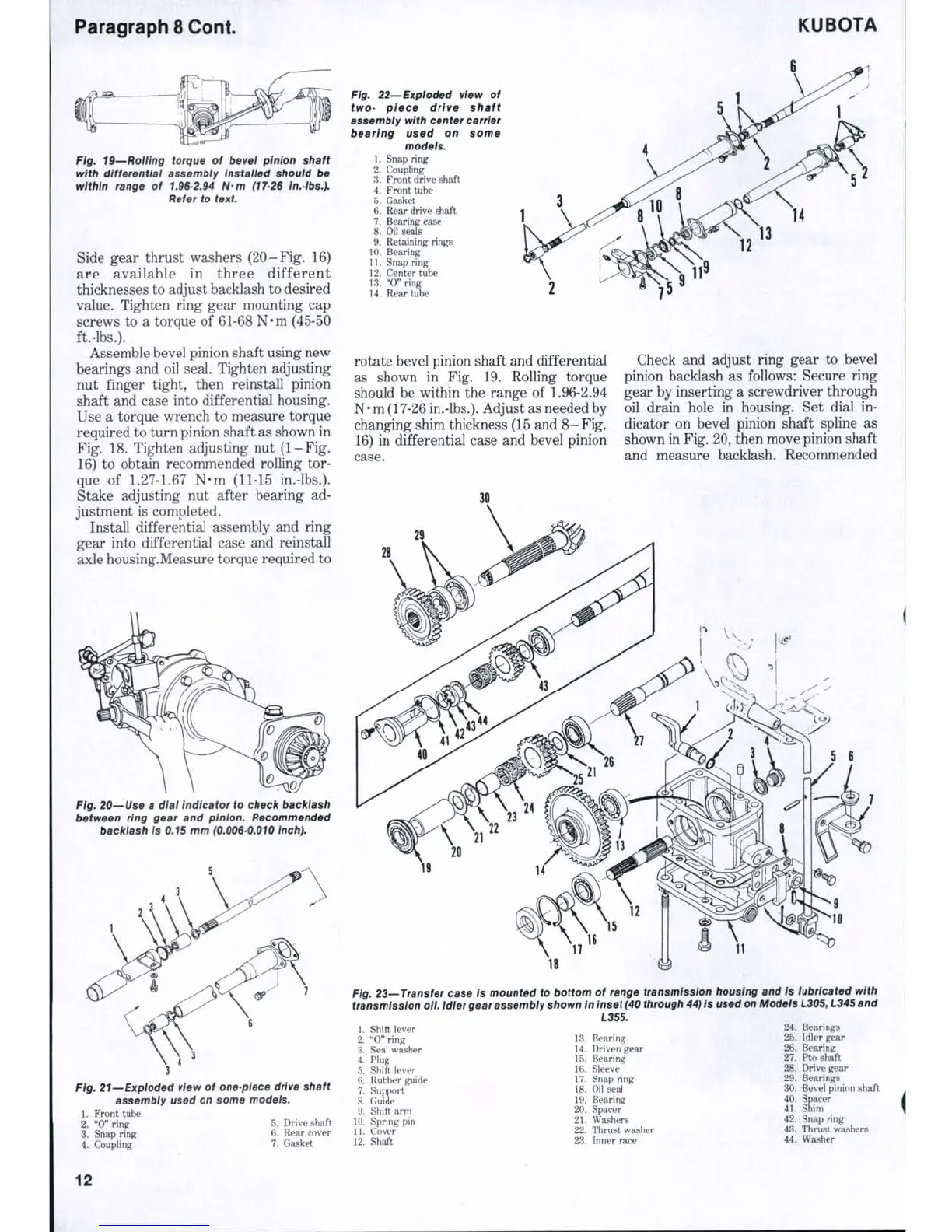

Fig. 23—Transfer case is mounted to bottom of range transmission housing and is lubricated with

transmission ott.

Idler

gear assembly shown in Inset

(40

through

44)

is used on Modeis

L305,

L345

and

L355.

1.

Shift lever

2.

"0" ring

3.

Seal washer

4.

Plug

5.

Shift lever

6. Rubber guide

7.

Support

8. Guide

9. Shift arm

10.

Spring pin

11.

Cover

12.

Shaft

13.

Bearing

14.

Driven gear

15.

Bearing

16.

Sleeve

17.

Snap ring

18.

Oil seal

19.

Bearing

20.

Spacer

21.

Washers

22.

Thrust washer

23.

Inner race

24.

Bearings

25.

Idler gear

26.

Bearing

27.

Pto shaft

28.

Drive gear

29.

Bearings

30.

Bevel pinion shaft

40.

Spacer

41.

Shim

42.

Snap ring

43.

Thrust washers

44.

Washer

12

Loading...

Loading...