Do you have a question about the Lainox NABOO NAGB101 and is the answer not in the manual?

Room ventilation requirements for gas installations and extractor hoods.

Requirements for flue gas extraction stack or system for gas appliances.

Gas supply plumbing installation according to regulations and fast-acting shutoff valve.

Guidelines for lifting and handling floor-standing ovens using forklifts or jack pallets.

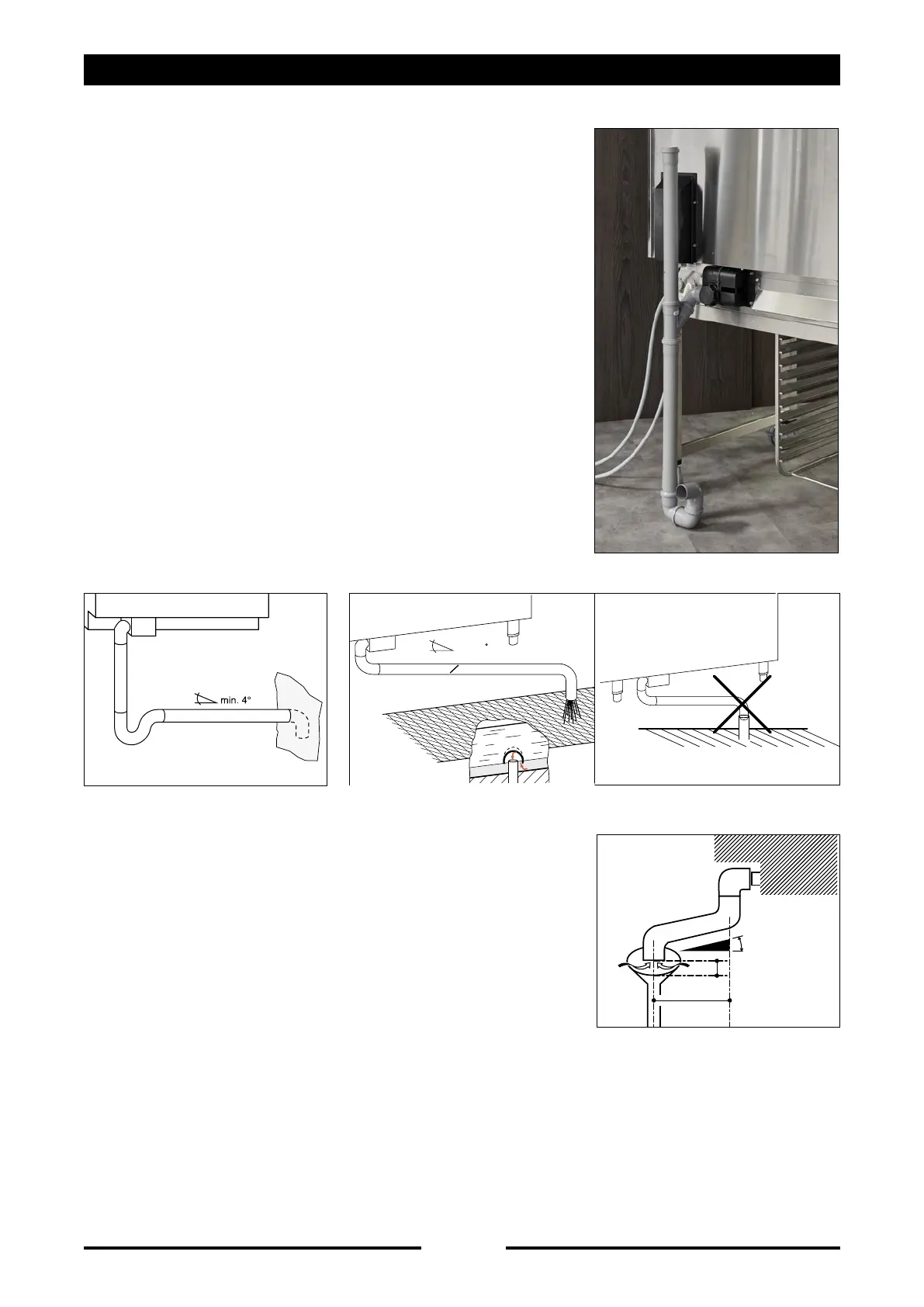

Instructions for positioning and setting COMBICLEAN detergent cartridge/container.

Instructions for positioning and setting CALFREE descaler cartridge/container.

Procedure for replacing the COMBICLEAN detergent cartridge.

Instructions for positioning and setting both COMBICLEAN and CALFREE cartridges.

Specifications for gas supply pipe selection, connection, and shutoff valve.

Guidelines for exhausting flue gases based on installation type and room ventilation.

Procedure for checking chamber burner depth and fan speed.

How to test burner function, block sequences, and use CLIMA button.

Checking combustion CO (ppm) and CO2 (%) values with an instrument.

Checking appliance and installation after connection, including protective film, vents, and leaks.