Page 13

17 – Clean inside of each burner with a bottle cleaning

brush. See figure 21.

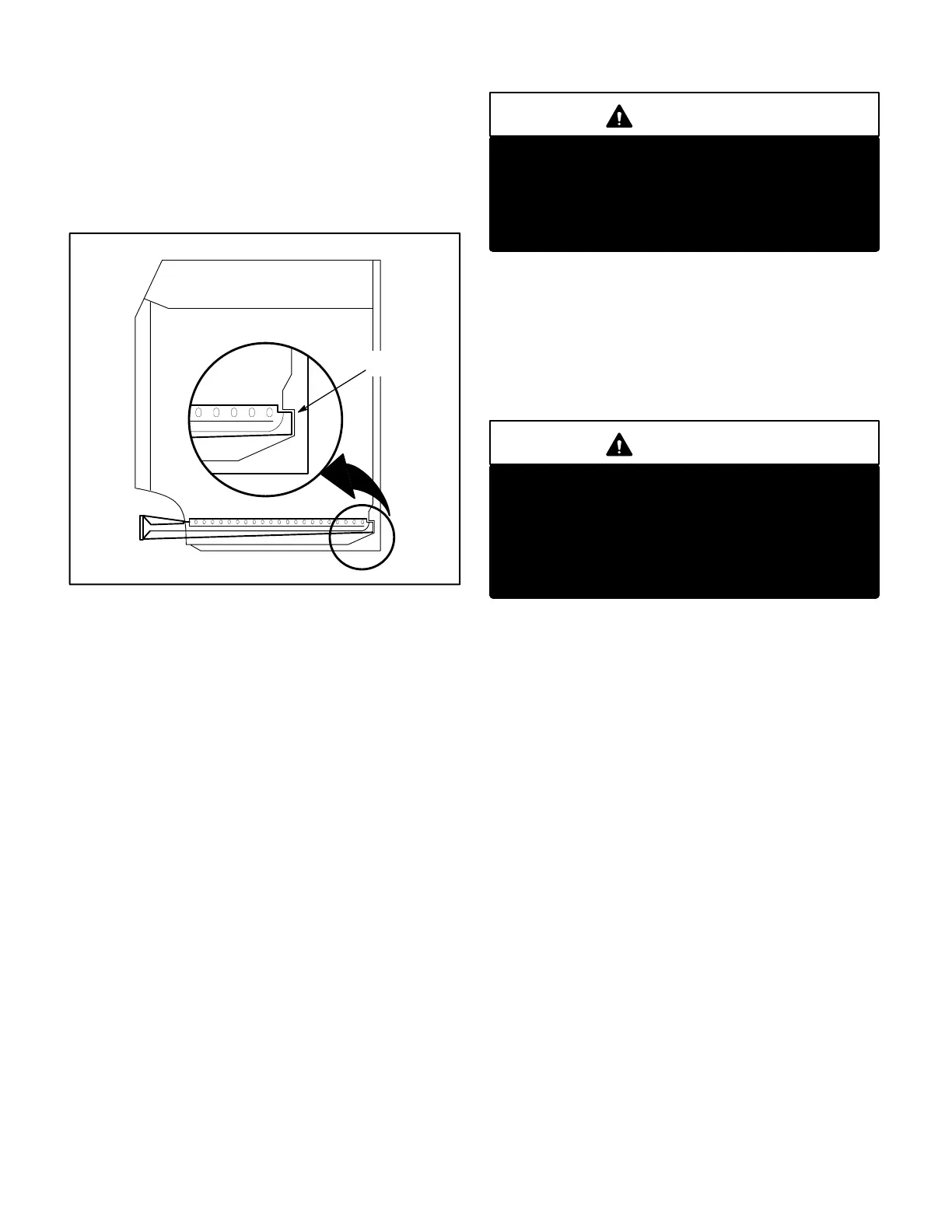

18 – Replace burners making sure to fully engage in rear

receiving slot in heat exchanger. See figure 22. Re-

secure gas manifold and supply piping.

FIGURE 22

BURNER SLOT ENGAGEMENT

ENGAGE BURNER

IN SLOT

19 – Resecure damper assembly, damper prove switch

cover and burner box top. Carefully open damper

by hand to ensure that the damper spring closes

damper correctly and that the damper prove switch

is engaged when damper is open.

CAUTION

Potential for unit damage.

Use extreme care when opening damper door to

prevent permanent damage to the damper door.

Can cause damage to damper motor resulting in

improper furnace operation.

20 – Install flue restrictor (50E models only).

21 – Before replacing draft hood, flue pipe and access

panels, inspect draft hood gasket. Replace gasket if

necessary.

22 – Carefully check all piping connections (factory and

field) for gas leaks. Use a leak detecting solution or

other preferred means.

CAUTION

Potential for gas leaks, fire or explosion.

Some soaps used for leak detection are corrosive

to certain metals. Carefully clean piping thor-

oughly after leak detection has been completed.

Can cause damage to piping resulting in gas leaks,

fire or explosion.

23 – Turn on gas and electrical supply.

E – Electrical

1 – Check all wiring for loose connections.

2 – Check for correct voltage.

3 – Check amp–draw on blower motor.

Loading...

Loading...